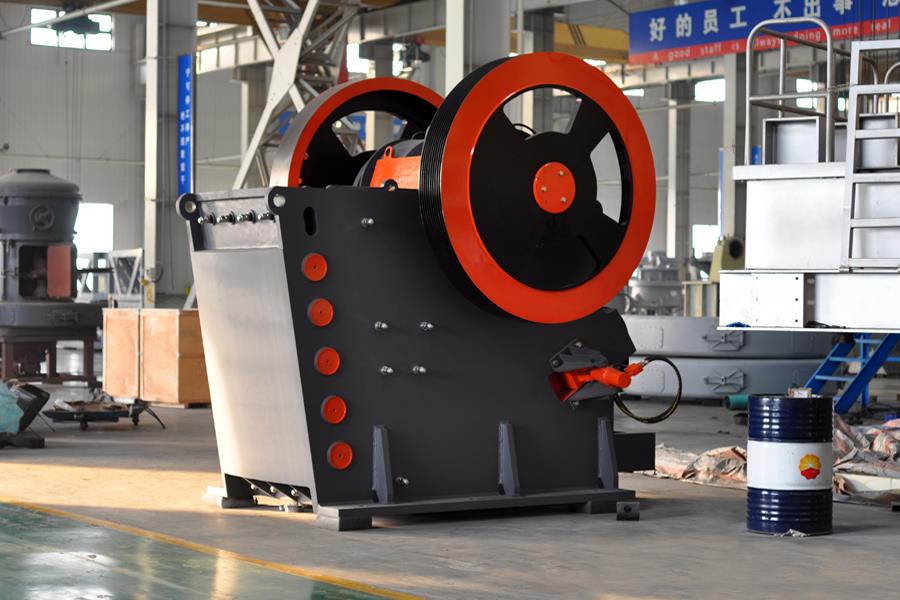

In the process of using the crusher, it is inevitable that you will encounter some unexpected situations and common failures. But please don't be too anxious, because these problems can usually be solved by some related knowledge and solutio

In the process of using the crusher, it is inevitable that you will encounter some unexpected situations and common failures. But please don't be too anxious, because these problems can usually be solved by some related knowledge and solutions. I have collected some common failures and their solutions for you, and hope to provide useful help for you.

A. Sudden stoppage of the main machine of the crusher. The causes of the main machine stopping may be the following situations, please check according to the actual situation:

1. The discharge port is blocked, resulting in material blockage.

2. The v-belt driving the groove wheel is too loose, causing the belt to slip.

3. The eccentric shaft tightening bushing is loose, making the eccentric shaft stuck and unable to rotate.

4. The voltage of the working site is too low, the main machine can not cope with the crushing of large materials.

5. The bearing is damaged.

For the above situation, the following solutions can be adopted: clear the blockage at the discharge port to ensure the material can be discharged smoothly; tighten or replace the v-belt; reinstall or replace the tightening bushing; adjust the voltage of the workplace to meet the requirements of the main machine; replace the damaged bearing, etc.

Second, the crusher mainframe slot wheel and moving jaw are running normally, but the crushing work stops. The cause of this situation may be the broken tension spring, broken tie rod or dislodged or broken elbow plate.

The solution is to replace the broken tension spring, replace the broken tie rod and reinstall or replace the elbow plate.

Third, the reasons for the broken elbow plate may be

1. The main machine is overloaded or the feeding material exceeds the size of the crushing cavity opening.

2. Non-crushing materials enter the crushing chamber.

3. The elbow plate and elbow plate pad are not parallel, there is deflection.

4. The casting has serious casting defects.

Solution:

1. Replace the elbow plate of the crusher and control the feed size to avoid overloading the main machine.

2. Replace the elbow plate and take measures to prevent non-crushing materials from entering the crushing chamber.

3. Replace the elbow plate and replace the worn elbow plate pad, and install the elbow plate correctly.

4. Replace the qualified elbow plate.

If you are interested in our products or have questions, welcome to call our telephone +86-19937863975 or click "Business" online consultation, our customer service staff will provide you with detailed answers, considerate service, your satisfaction will be our unremitting impetus to move forward, welcome your click consultation.

Previous: SMP Crusher

Next: SMP Crusher

In the process of using the crusher, it is inevitable that you will encounter some unexpected situations and common failures. But please don't be too anxious, because these problems can usually be solved by some related knowledge and solutio

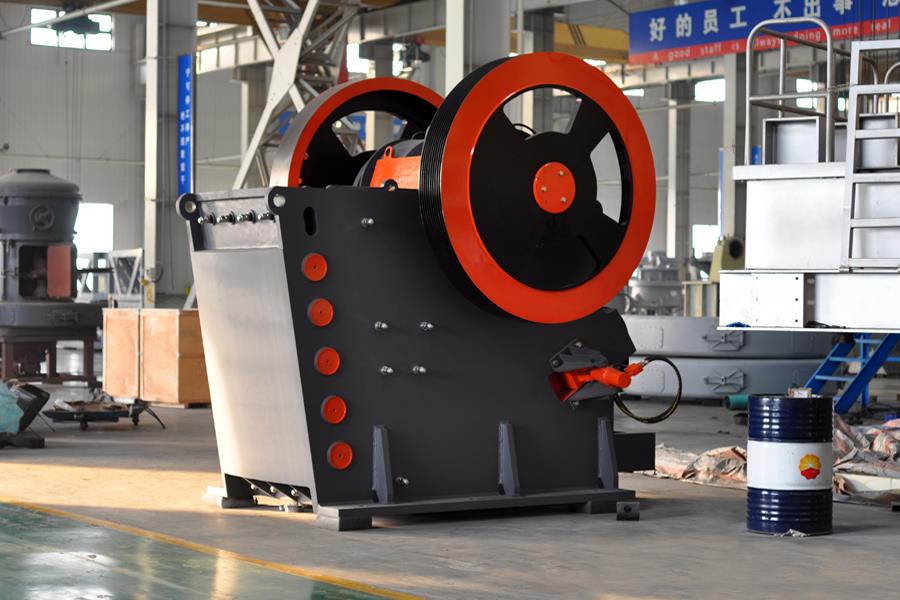

In the process of using the crusher, it is inevitable that you will encounter some unexpected situations and common failures. But please don't be too anxious, because these problems can usually be solved by some related knowledge and solutions. I have collected some common failures and their solutions for you, and hope to provide useful help for you.

A. Sudden stoppage of the main machine of the crusher. The causes of the main machine stopping may be the following situations, please check according to the actual situation:

1. The discharge port is blocked, resulting in material blockage.

2. The v-belt driving the groove wheel is too loose, causing the belt to slip.

3. The eccentric shaft tightening bushing is loose, making the eccentric shaft stuck and unable to rotate.

4. The voltage of the working site is too low, the main machine can not cope with the crushing of large materials.

5. The bearing is damaged.

For the above situation, the following solutions can be adopted: clear the blockage at the discharge port to ensure the material can be discharged smoothly; tighten or replace the v-belt; reinstall or replace the tightening bushing; adjust the voltage of the workplace to meet the requirements of the main machine; replace the damaged bearing, etc.

Second, the crusher mainframe slot wheel and moving jaw are running normally, but the crushing work stops. The cause of this situation may be the broken tension spring, broken tie rod or dislodged or broken elbow plate.

The solution is to replace the broken tension spring, replace the broken tie rod and reinstall or replace the elbow plate.

Third, the reasons for the broken elbow plate may be

1. The main machine is overloaded or the feeding material exceeds the size of the crushing cavity opening.

2. Non-crushing materials enter the crushing chamber.

3. The elbow plate and elbow plate pad are not parallel, there is deflection.

4. The casting has serious casting defects.

Solution:

1. Replace the elbow plate of the crusher and control the feed size to avoid overloading the main machine.

2. Replace the elbow plate and take measures to prevent non-crushing materials from entering the crushing chamber.

3. Replace the elbow plate and replace the worn elbow plate pad, and install the elbow plate correctly.

4. Replace the qualified elbow plate.

If you are interested in our products or have questions, welcome to call our telephone +86-19937863975 or click "Business" online consultation, our customer service staff will provide you with detailed answers, considerate service, your satisfaction will be our unremitting impetus to move forward, welcome your click consultation.

Previous: SMP Crusher

Next: SMP Crusher

Annual production capacity of 2 million tons of sand and gravel production line equipment configuration

Annual production capacity of 2 million tons of sand and gravel production line equipment configuration What sand making machine for quartz stone used in railroad construction

What sand making machine for quartz stone used in railroad construction open stone plant to make money, what equipment needs to be prepared

open stone plant to make money, what equipment needs to be prepared Granite Cone Crusher with a capacity of 280 tons per hour

Granite Cone Crusher with a capacity of 280 tons per hour 200 tons per hour mobile concrete crusher

200 tons per hour mobile concrete crusher Annual production capacity of 2 million tons of sand and gravel production line equipment configuration

Annual production capacity of 2 million tons of sand and gravel production line equipment configuration What sand making machine for quartz stone used in railroad construction

What sand making machine for quartz stone used in railroad construction open stone plant to make money, what equipment needs to be prepared

open stone plant to make money, what equipment needs to be prepared Granite Cone Crusher with a capacity of 280 tons per hour

Granite Cone Crusher with a capacity of 280 tons per hour 200 tons per hour mobile concrete crusher

200 tons per hour mobile concrete crusher