LM series vertical mill (vertical mill) is a large scale grinding equipment designed and improved by Leming Heavy Industry Technology after years of intensive design to solve the technical problems of low output and high energy consumption of industria

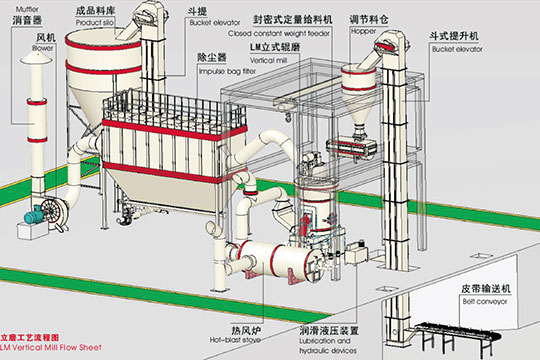

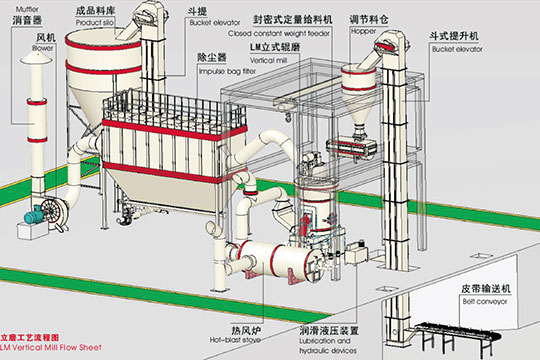

LM series vertical mill (vertical mill) is a large scale grinding equipment designed and improved by Leming Heavy Industry Technology after years of intensive design to solve the technical problems of low output and high energy consumption of industrial mills, absorbing the advanced technology from Europe and combining our advanced mill design and manufacturing concept and market demand for many years. It is specially used in the glass fiber industry for the large output and high fineness grinding of chlorite powder; in the coal industry for the large output powder production of coal gangue powder; in the chemical industry for the large output powder production of various chemical raw materials; in the non-metallic mineral industry for the large scale powder production and preparation of hundreds of ores of low, medium and high hardness, as well as the large output powder preparation of various materials in more than 100 other industries.

LM130N Vertical Mill, Process Slag ,8tph

Equipment: LM130N Vertical Mill

Material: Slag

Capacity: 6tph

Output size: 325 mesh

Location: Thailand

Using time: 2014

Working Principle

The slag vertical mill is a negative-pressure air-sweep type grinding equipment, which dries the slag and grinds the slag. When working, the main motor drives the grinding table to rotate through the reducer, and at the same time, the hot air enters the body of the vertical mill from the air inlet, and the material falls from the discharge port to the center of the grinding table. In the area of the upper grinding roller, it is crushed by the grinding roller, and the bulk material is crushed directly, and the fine-grained material is extruded to form a material bed for inter-particle crushing. The crushed material continues to move toward the edge of the grinding table until it is taken away by the strong air flow at the wind ring, and the larger particulate material falls back onto the grinding table to continue crushing. When the material in the air flow passes through the upper separator, the rotor under the action of the blades, the coarse particles are returned to the grinding table for grinding, and the qualified fine powder is discharged with the airflow and collected by the system's powder collector. The collected powder is the product of the vertical grinding. When the iron and other debris mixed with the material move to the edge of the grinding table with the material, they cannot be blown up by the wind due to their own weight.

Customer satisfaction is SMPCRUSHER's goal. If you have any questions or requests for quotations, please call our hotline or click "Online Business Link" and we will contact you immediately!

Hot Sale: patented technology, high productivity, environmental protection and energy saving.

Previous: SMP Crusher

Next: SMP Crusher

LM series vertical mill (vertical mill) is a large scale grinding equipment designed and improved by Leming Heavy Industry Technology after years of intensive design to solve the technical problems of low output and high energy consumption of industria

LM series vertical mill (vertical mill) is a large scale grinding equipment designed and improved by Leming Heavy Industry Technology after years of intensive design to solve the technical problems of low output and high energy consumption of industrial mills, absorbing the advanced technology from Europe and combining our advanced mill design and manufacturing concept and market demand for many years. It is specially used in the glass fiber industry for the large output and high fineness grinding of chlorite powder; in the coal industry for the large output powder production of coal gangue powder; in the chemical industry for the large output powder production of various chemical raw materials; in the non-metallic mineral industry for the large scale powder production and preparation of hundreds of ores of low, medium and high hardness, as well as the large output powder preparation of various materials in more than 100 other industries.

LM130N Vertical Mill, Process Slag ,8tph

Equipment: LM130N Vertical Mill

Material: Slag

Capacity: 6tph

Output size: 325 mesh

Location: Thailand

Using time: 2014

Working Principle

The slag vertical mill is a negative-pressure air-sweep type grinding equipment, which dries the slag and grinds the slag. When working, the main motor drives the grinding table to rotate through the reducer, and at the same time, the hot air enters the body of the vertical mill from the air inlet, and the material falls from the discharge port to the center of the grinding table. In the area of the upper grinding roller, it is crushed by the grinding roller, and the bulk material is crushed directly, and the fine-grained material is extruded to form a material bed for inter-particle crushing. The crushed material continues to move toward the edge of the grinding table until it is taken away by the strong air flow at the wind ring, and the larger particulate material falls back onto the grinding table to continue crushing. When the material in the air flow passes through the upper separator, the rotor under the action of the blades, the coarse particles are returned to the grinding table for grinding, and the qualified fine powder is discharged with the airflow and collected by the system's powder collector. The collected powder is the product of the vertical grinding. When the iron and other debris mixed with the material move to the edge of the grinding table with the material, they cannot be blown up by the wind due to their own weight.

Customer satisfaction is SMPCRUSHER's goal. If you have any questions or requests for quotations, please call our hotline or click "Online Business Link" and we will contact you immediately!

Hot Sale: patented technology, high productivity, environmental protection and energy saving.

Previous: SMP Crusher

Next: SMP Crusher

How sand and gravel aggregate equipment is environmentally friendly, sand and gravel aggregate equipment price

How sand and gravel aggregate equipment is environmentally friendly, sand and gravel aggregate equipment price Crawler mobile break performance characteristics How much

Crawler mobile break performance characteristics How much How to choose how much is a large stone machine with a daily capacity of 6000 tons

How to choose how much is a large stone machine with a daily capacity of 6000 tons Limestone crushing production line common equipment models and selection guide

Limestone crushing production line common equipment models and selection guide 4000 tons/day bauxite grinding production site

4000 tons/day bauxite grinding production site How sand and gravel aggregate equipment is environmentally friendly, sand and gravel aggregate equipment price

How sand and gravel aggregate equipment is environmentally friendly, sand and gravel aggregate equipment price Crawler mobile break performance characteristics How much

Crawler mobile break performance characteristics How much How to choose how much is a large stone machine with a daily capacity of 6000 tons

How to choose how much is a large stone machine with a daily capacity of 6000 tons Limestone crushing production line common equipment models and selection guide

Limestone crushing production line common equipment models and selection guide 4000 tons/day bauxite grinding production site

4000 tons/day bauxite grinding production site