Amidst the rapid development of the building materials industry, a renowned cement company in Chongqing has taken a significant step towards transformation and upgrading, thanks to its keen market insight and forward-looking strategic planning. Facing

Amidst the rapid development of the building materials industry, a renowned cement company in Chongqing has taken a significant step towards transformation and upgrading, thanks to its keen market insight and forward-looking strategic planning. Facing the continued boom in the sand and gravel market, the company decisively invested in building a brand-new sand and gravel aggregate production base, aiming to further enhance its market competitiveness through a complete industry chain layout.

More Ore Crushing Equipment Cases

Project Background and Decision-Making

This Chongqing-based cement giant not only possesses mature experience in operating mixing plants but also has accumulated profound professional expertise in the building materials field. To adapt to industry changes, the company decided to expand into the sand and gravel aggregate sector, leveraging its abundant limestone resources to build a complete production system from raw materials to finished products. In equipment selection, the company partnered with Shibang Group, precisely positioning and scientifically configuring jaw crushers, impact crushers, and sand making machines to ensure the production of multi-specification, high-quality aggregate products that meet both the high-standard requirements of high-speed rail construction and the daily industrial needs of cement plants.

Project Overview

Capacity: 1000 tons/hour

Raw Materials: High-quality limestone

Finished Product Specifications: Covers 0-5-10-20-31.5mm conventional sand and gravel aggregates and 3-8cm industrial materials

Core Equipment: Equipped with a C6X jaw crusher, two CI5X impact crushers, and two VSI6X sand making machines

Processing Technology: Innovative integration of dry and wet processes to achieve efficient and environmentally friendly production

Application Areas: Finished aggregates are widely used in high-speed rail construction and lime kilns, among other industrial fields.

Construction Highlights and Technological Innovations

Process Advantages: Utilizes multi-stage crushing and screening technology to ensure excellent finished product quality that meets relevant national standards.

Environmental Design: Fully enclosed plant operation, dust emissions are far below national standards, coupled with a professional wastewater treatment system to achieve green production.

Intelligent Management: Introduces advanced technologies such as a PLC central control system and an automatic loading system to achieve intelligent monitoring and control of the entire production process.

Service Model: Shibang Group provides EPC general contracting services, ensuring high standards throughout the entire process from design to operation and maintenance, and establishing a nationwide service network to ensure worry-free operation for clients.

Equipment Recommendations: Leading a New Industry Trend

C6X Jaw Crusher: With its superior performance and high-efficiency crushing capacity, it has become the preferred equipment for coarse crushing.

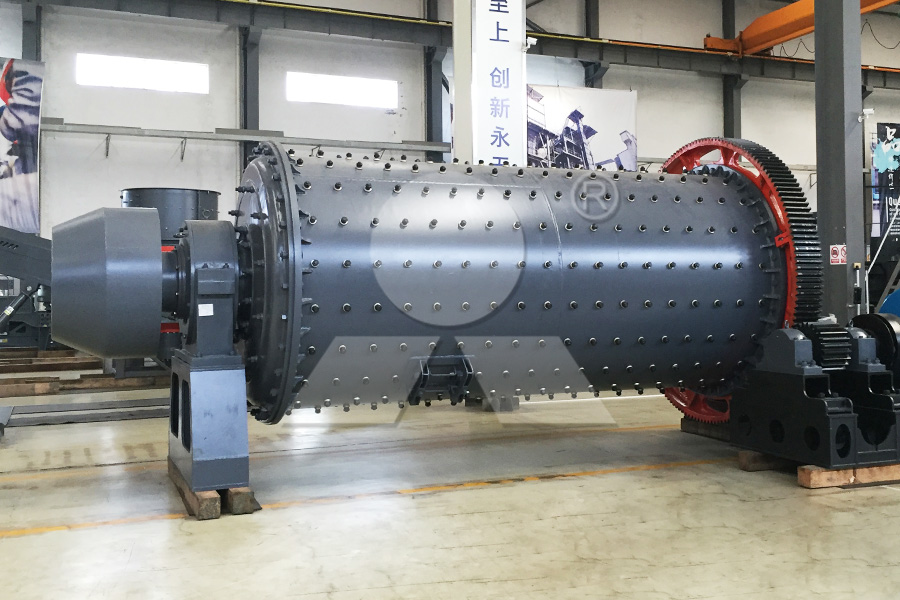

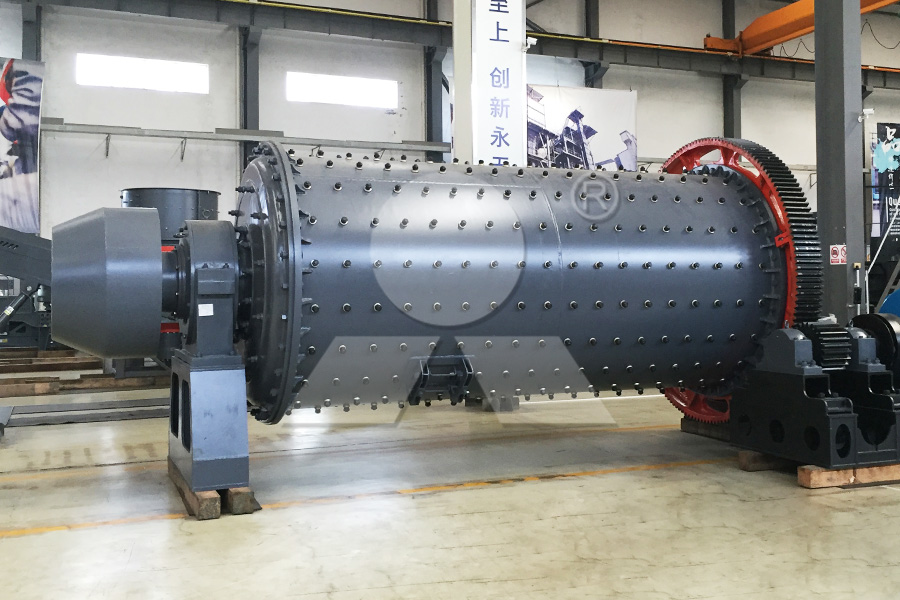

CI5X Impact Crusher: As an upgraded version of the traditional impact crusher, its high efficiency and energy saving features have won widespread market recognition.

VSI6X Impact Crusher: Integrating shaping and sand making, it produces perfect finished particle shapes, meeting the stringent requirements of high-end construction projects.

The successful implementation of this project not only marks a solid step forward for this cement company on its path of transformation and upgrading, but also sets a green, efficient, and intelligent production benchmark for the entire sand and gravel aggregate industry. In the future, the company will continue to uphold the concept of innovative development and contribute more to promoting industry progress.

Previous: SMP Crusher

Next: SMP Crusher

Amidst the rapid development of the building materials industry, a renowned cement company in Chongqing has taken a significant step towards transformation and upgrading, thanks to its keen market insight and forward-looking strategic planning. Facing

Amidst the rapid development of the building materials industry, a renowned cement company in Chongqing has taken a significant step towards transformation and upgrading, thanks to its keen market insight and forward-looking strategic planning. Facing the continued boom in the sand and gravel market, the company decisively invested in building a brand-new sand and gravel aggregate production base, aiming to further enhance its market competitiveness through a complete industry chain layout.

More Ore Crushing Equipment Cases

Project Background and Decision-Making

This Chongqing-based cement giant not only possesses mature experience in operating mixing plants but also has accumulated profound professional expertise in the building materials field. To adapt to industry changes, the company decided to expand into the sand and gravel aggregate sector, leveraging its abundant limestone resources to build a complete production system from raw materials to finished products. In equipment selection, the company partnered with Shibang Group, precisely positioning and scientifically configuring jaw crushers, impact crushers, and sand making machines to ensure the production of multi-specification, high-quality aggregate products that meet both the high-standard requirements of high-speed rail construction and the daily industrial needs of cement plants.

Project Overview

Capacity: 1000 tons/hour

Raw Materials: High-quality limestone

Finished Product Specifications: Covers 0-5-10-20-31.5mm conventional sand and gravel aggregates and 3-8cm industrial materials

Core Equipment: Equipped with a C6X jaw crusher, two CI5X impact crushers, and two VSI6X sand making machines

Processing Technology: Innovative integration of dry and wet processes to achieve efficient and environmentally friendly production

Application Areas: Finished aggregates are widely used in high-speed rail construction and lime kilns, among other industrial fields.

Construction Highlights and Technological Innovations

Process Advantages: Utilizes multi-stage crushing and screening technology to ensure excellent finished product quality that meets relevant national standards.

Environmental Design: Fully enclosed plant operation, dust emissions are far below national standards, coupled with a professional wastewater treatment system to achieve green production.

Intelligent Management: Introduces advanced technologies such as a PLC central control system and an automatic loading system to achieve intelligent monitoring and control of the entire production process.

Service Model: Shibang Group provides EPC general contracting services, ensuring high standards throughout the entire process from design to operation and maintenance, and establishing a nationwide service network to ensure worry-free operation for clients.

Equipment Recommendations: Leading a New Industry Trend

C6X Jaw Crusher: With its superior performance and high-efficiency crushing capacity, it has become the preferred equipment for coarse crushing.

CI5X Impact Crusher: As an upgraded version of the traditional impact crusher, its high efficiency and energy saving features have won widespread market recognition.

VSI6X Impact Crusher: Integrating shaping and sand making, it produces perfect finished particle shapes, meeting the stringent requirements of high-end construction projects.

The successful implementation of this project not only marks a solid step forward for this cement company on its path of transformation and upgrading, but also sets a green, efficient, and intelligent production benchmark for the entire sand and gravel aggregate industry. In the future, the company will continue to uphold the concept of innovative development and contribute more to promoting industry progress.

Previous: SMP Crusher

Next: SMP Crusher

Is the Shibang HST750 cone crusher any good?

Is the Shibang HST750 cone crusher any good? Configuration scheme for a 10,000-ton-per-day stone production line

Configuration scheme for a 10,000-ton-per-day stone production line Tracked crushing equipment: the smart choice for hard and soft rock.

Tracked crushing equipment: the smart choice for hard and soft rock. How to configure a granite sand and gravel aggregate production line with an output of 1000 tons per hour?

How to configure a granite sand and gravel aggregate production line with an output of 1000 tons per hour? What should be considered when configuring a pebble sand making production line?

What should be considered when configuring a pebble sand making production line? Is the Shibang HST750 cone crusher any good?

Is the Shibang HST750 cone crusher any good? Configuration scheme for a 10,000-ton-per-day stone production line

Configuration scheme for a 10,000-ton-per-day stone production line Tracked crushing equipment: the smart choice for hard and soft rock.

Tracked crushing equipment: the smart choice for hard and soft rock. How to configure a granite sand and gravel aggregate production line with an output of 1000 tons per hour?

How to configure a granite sand and gravel aggregate production line with an output of 1000 tons per hour? What should be considered when configuring a pebble sand making production line?

What should be considered when configuring a pebble sand making production line?