In the mineral processing field, silica minerals such as vein quartz, quartzite, and quartz sandstone, due to the widespread application of their main component, silicon dioxide, have become important raw materials for manufacturing key materials such

In the mineral processing field, silica minerals such as vein quartz, quartzite, and quartz sandstone, due to the widespread application of their main component, silicon dioxide, have become important raw materials for manufacturing key materials such as acidic refractory bricks, glass, ceramics, and silicate cement. With the continuous growth of market demand, the silica processing industry shows broad development prospects. So, on this path full of opportunities, how to choose suitable silica processing production line equipment? Especially for production needs of 100-150 tons per hour, how should the configuration be done and costs estimated?

More Ore Crushing Production Lines

I. Optimal Selection of Silica Processing Production Line Equipment

Due to its high hardness, silica requires fine processes such as feeding, crushing, sand making/grinding, and screening during processing. Shibang Group, as an industry leader, provides a complete set of efficient and reliable solutions:

Coarse Crushing Stage: The PE series jaw crusher is recommended. With its powerful crushing capacity and wide adaptability, it easily handles the initial crushing tasks of silica. The equipment has a reasonable structural design, and the jaw plates are made of high-manganese steel wear-resistant material to ensure long-term stable operation.

Medium and Fine Crushing Stage: The system then connects to an HP series cone crusher, utilizing its advanced hydraulic system and layered crushing principle to achieve efficient fine crushing of silica. The finished product has excellent particle shape and low needle-like and flaky content, meeting high-quality production requirements.

Sand Making/Grinding Stage: For further sand making, a VSI series sand making machine can be selected. Its deep-cavity impeller design ensures high throughput and efficient operation, while being environmentally friendly and producing high-quality finished sand. For grinding, a Raymond mill, such as the 4525 model, can be selected to meet fine processing needs.

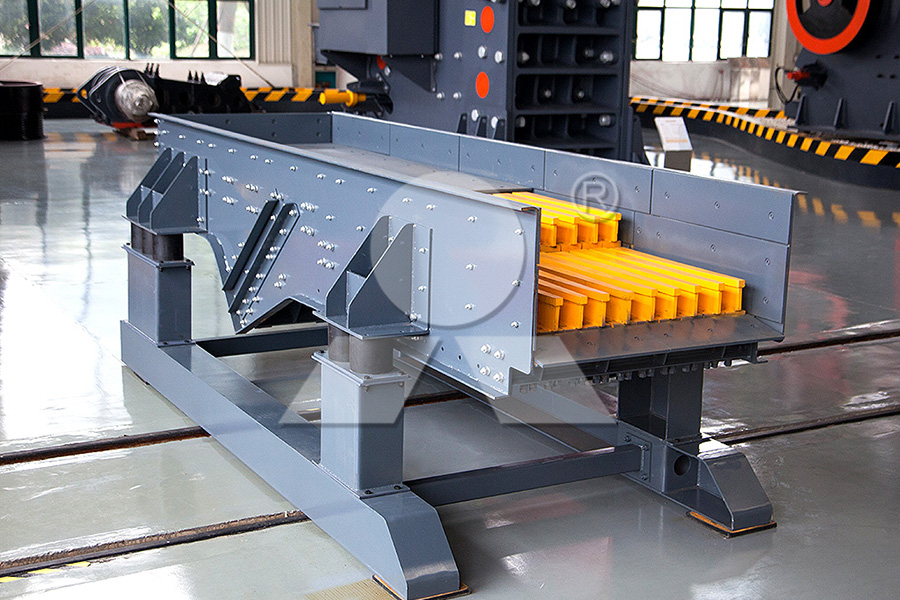

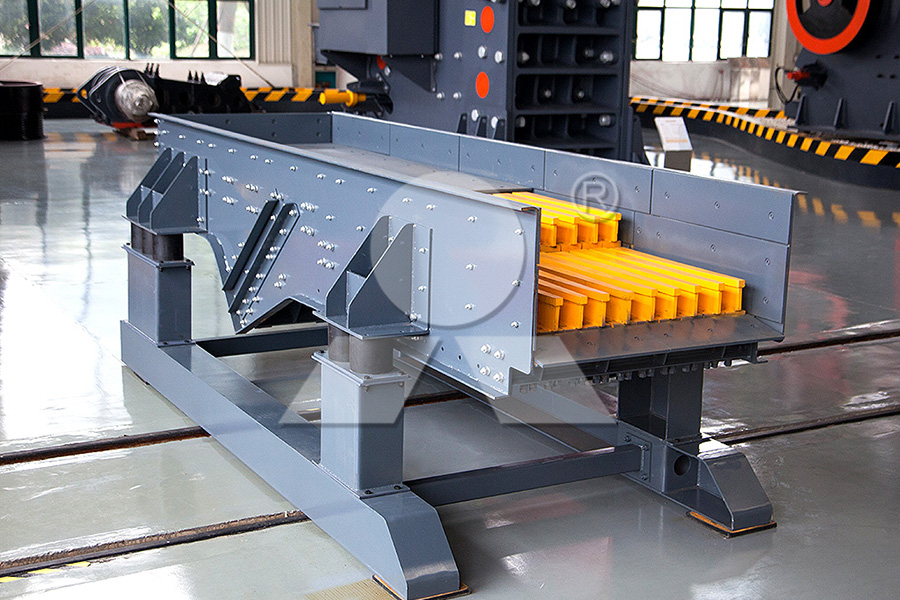

Auxiliary Equipment: The production line also needs to be equipped with devices such as a ZSW series vibrating feeder and a YK series vibrating screen to ensure uniform material feeding and precise screening, improving overall production efficiency.

II. Equipment Configuration: For silica processing needs of 100-150 tons per hour, the above equipment combination can be perfectly matched to achieve efficient and stable continuous production. Specific costs vary depending on equipment models, configuration schemes, and market fluctuations.

On the challenging yet promising path of silica processing, choosing Shibang Group's advanced equipment is undoubtedly a crucial step towards efficient and high-quality production. We are committed to providing our clients with comprehensive solutions and superior service, working together to create a bright future for the silica processing industry.

Previous: SMP Crusher

Next: SMP Crusher

In the mineral processing field, silica minerals such as vein quartz, quartzite, and quartz sandstone, due to the widespread application of their main component, silicon dioxide, have become important raw materials for manufacturing key materials such

In the mineral processing field, silica minerals such as vein quartz, quartzite, and quartz sandstone, due to the widespread application of their main component, silicon dioxide, have become important raw materials for manufacturing key materials such as acidic refractory bricks, glass, ceramics, and silicate cement. With the continuous growth of market demand, the silica processing industry shows broad development prospects. So, on this path full of opportunities, how to choose suitable silica processing production line equipment? Especially for production needs of 100-150 tons per hour, how should the configuration be done and costs estimated?

More Ore Crushing Production Lines

I. Optimal Selection of Silica Processing Production Line Equipment

Due to its high hardness, silica requires fine processes such as feeding, crushing, sand making/grinding, and screening during processing. Shibang Group, as an industry leader, provides a complete set of efficient and reliable solutions:

Coarse Crushing Stage: The PE series jaw crusher is recommended. With its powerful crushing capacity and wide adaptability, it easily handles the initial crushing tasks of silica. The equipment has a reasonable structural design, and the jaw plates are made of high-manganese steel wear-resistant material to ensure long-term stable operation.

Medium and Fine Crushing Stage: The system then connects to an HP series cone crusher, utilizing its advanced hydraulic system and layered crushing principle to achieve efficient fine crushing of silica. The finished product has excellent particle shape and low needle-like and flaky content, meeting high-quality production requirements.

Sand Making/Grinding Stage: For further sand making, a VSI series sand making machine can be selected. Its deep-cavity impeller design ensures high throughput and efficient operation, while being environmentally friendly and producing high-quality finished sand. For grinding, a Raymond mill, such as the 4525 model, can be selected to meet fine processing needs.

Auxiliary Equipment: The production line also needs to be equipped with devices such as a ZSW series vibrating feeder and a YK series vibrating screen to ensure uniform material feeding and precise screening, improving overall production efficiency.

II. Equipment Configuration: For silica processing needs of 100-150 tons per hour, the above equipment combination can be perfectly matched to achieve efficient and stable continuous production. Specific costs vary depending on equipment models, configuration schemes, and market fluctuations.

On the challenging yet promising path of silica processing, choosing Shibang Group's advanced equipment is undoubtedly a crucial step towards efficient and high-quality production. We are committed to providing our clients with comprehensive solutions and superior service, working together to create a bright future for the silica processing industry.

Previous: SMP Crusher

Next: SMP Crusher

Gansu Longnan Shibang 500-ton-per-hour limestone crushing and sand making project

Gansu Longnan Shibang 500-ton-per-hour limestone crushing and sand making project What types of sand making machines have a capacity of 100 tons per hour? How much does one cost?

What types of sand making machines have a capacity of 100 tons per hour? How much does one cost? Comparison of differences between different cone crushers

Comparison of differences between different cone crushers Shibang Gansu Lanzhou 500-ton-per-hour tuff crushing and sand making project

Shibang Gansu Lanzhou 500-ton-per-hour tuff crushing and sand making project C6X Jaw Crusher: Leading the Way in High-Quality Crushing in the Sand and Gravel Industry

C6X Jaw Crusher: Leading the Way in High-Quality Crushing in the Sand and Gravel Industry Gansu Longnan Shibang 500-ton-per-hour limestone crushing and sand making project

Gansu Longnan Shibang 500-ton-per-hour limestone crushing and sand making project What types of sand making machines have a capacity of 100 tons per hour? How much does one cost?

What types of sand making machines have a capacity of 100 tons per hour? How much does one cost? Comparison of differences between different cone crushers

Comparison of differences between different cone crushers Shibang Gansu Lanzhou 500-ton-per-hour tuff crushing and sand making project

Shibang Gansu Lanzhou 500-ton-per-hour tuff crushing and sand making project C6X Jaw Crusher: Leading the Way in High-Quality Crushing in the Sand and Gravel Industry

C6X Jaw Crusher: Leading the Way in High-Quality Crushing in the Sand and Gravel Industry