The selection of crusher is closely related to the scale of the mine. Mines of different sizes have differences in production requirements, material handling capacity, site conditions, etc., which will affect the selection of crusher. The following is

The selection of crusher is closely related to the scale of the mine. Mines of different sizes have differences in production requirements, material handling capacity, site conditions, etc., which will affect the selection of crusher. The following is a detailed explanation for you:

Small mines

Production requirements: Small mines have relatively low output, and do not require high processing capacity of crushers, but pay more attention to the flexibility and cost-effectiveness of equipment.

Material handling capacity: The amount of waste rock and tailings handled daily is small, usually between tens of tons and hundreds of tons.

Site conditions: The site is generally limited, it is difficult to accommodate large equipment, and there are certain requirements for the mobility of the equipment.

Recommended crusher: Small jaw crusher with small impact crusher is a common choice. Small jaw crusher has a simple structure and low price, which is suitable for primary crushing; small impact crusher can perform medium and fine crushing of materials, and the finished product has a better particle shape. The combination of the two can meet the basic production needs of small mines. In addition, the small model in the mobile crushing station is also suitable for small mines. It can be flexibly moved and conveniently transferred between different operating points.

Medium-sized mines

Production requirements: The output of medium-sized mines is at a medium level, and they have high requirements for the processing capacity, stability and durability of the crusher. At the same time, they hope that the equipment has a certain degree of automation to reduce labor costs.

Material processing volume: The daily processing volume ranges from several hundred tons to thousands of tons.

Site conditions: There is a relatively fixed work site, but the space is not very abundant. The equipment needs to occupy a reasonable area while ensuring the processing capacity.

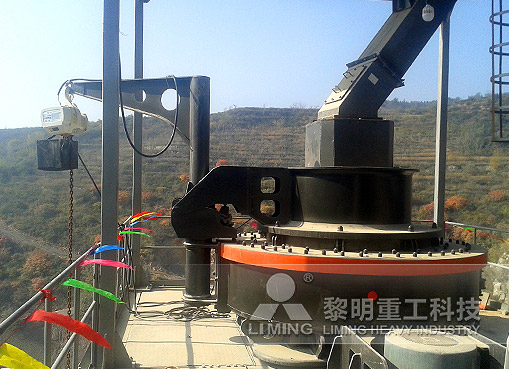

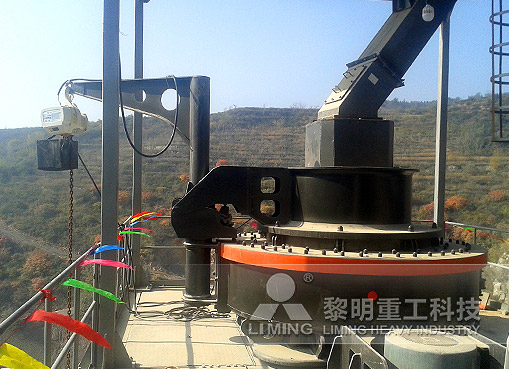

Recommended crusher: The combination of standard jaw crusher, cone crusher and impact crusher is a common solution. Jaw crusher is used for primary crushing, cone crusher is used for medium and fine crushing of materials with higher hardness, and impact crusher is used for medium and fine crushing of materials with lower hardness. It can be flexibly selected according to the characteristics of the material. This combination can not only ensure production efficiency, but also meet the requirements of medium-sized mines for equipment stability and durability.

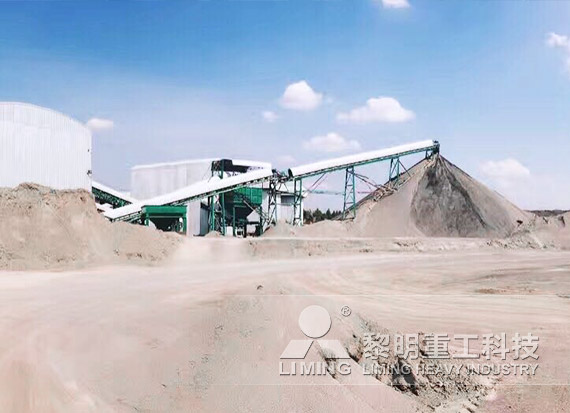

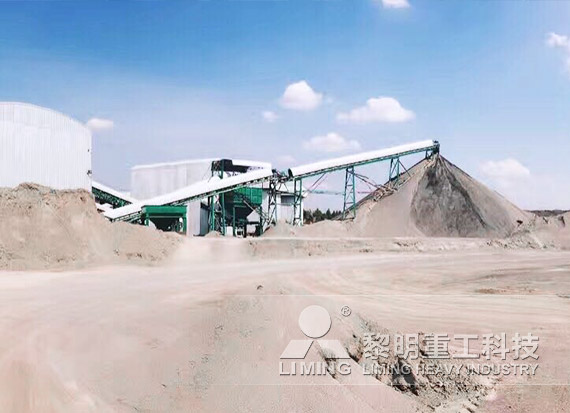

Large mines

Production requirements: Large mines have large outputs, and have extremely high requirements for the processing capacity, reliability and automation control level of the crusher. The equipment needs to be able to operate stably for a long time and have functions such as remote monitoring and fault diagnosis.

Material handling capacity: Daily handling capacity can reach thousands of tons or even tens of thousands of tons.

Site conditions: It has a vast operating site that can accommodate large equipment and has high requirements for equipment layout and logistics transportation.

Recommended crushers: Large jaw crushers, multi-cylinder hydraulic cone crushers and large impact crushers are the first choice for large mines. Large jaw crushers have strong processing capacity and can efficiently complete primary crushing tasks; multi-cylinder hydraulic cone crushers have the advantages of high automation, high crushing efficiency, and uniform product particle size, which are suitable for medium and fine crushing of materials with higher hardness; large impact crushers are suitable for medium and fine crushing of materials with lower hardness, which can ensure the particle shape of the finished product. In addition, large mines can also consider using large fixed production lines or large mobile crushing stations with integrated crushing and screening to improve production efficiency and automation level.

Previous: SMP Crusher

Next: SMP Crusher

The selection of crusher is closely related to the scale of the mine. Mines of different sizes have differences in production requirements, material handling capacity, site conditions, etc., which will affect the selection of crusher. The following is

The selection of crusher is closely related to the scale of the mine. Mines of different sizes have differences in production requirements, material handling capacity, site conditions, etc., which will affect the selection of crusher. The following is a detailed explanation for you:

Small mines

Production requirements: Small mines have relatively low output, and do not require high processing capacity of crushers, but pay more attention to the flexibility and cost-effectiveness of equipment.

Material handling capacity: The amount of waste rock and tailings handled daily is small, usually between tens of tons and hundreds of tons.

Site conditions: The site is generally limited, it is difficult to accommodate large equipment, and there are certain requirements for the mobility of the equipment.

Recommended crusher: Small jaw crusher with small impact crusher is a common choice. Small jaw crusher has a simple structure and low price, which is suitable for primary crushing; small impact crusher can perform medium and fine crushing of materials, and the finished product has a better particle shape. The combination of the two can meet the basic production needs of small mines. In addition, the small model in the mobile crushing station is also suitable for small mines. It can be flexibly moved and conveniently transferred between different operating points.

Medium-sized mines

Production requirements: The output of medium-sized mines is at a medium level, and they have high requirements for the processing capacity, stability and durability of the crusher. At the same time, they hope that the equipment has a certain degree of automation to reduce labor costs.

Material processing volume: The daily processing volume ranges from several hundred tons to thousands of tons.

Site conditions: There is a relatively fixed work site, but the space is not very abundant. The equipment needs to occupy a reasonable area while ensuring the processing capacity.

Recommended crusher: The combination of standard jaw crusher, cone crusher and impact crusher is a common solution. Jaw crusher is used for primary crushing, cone crusher is used for medium and fine crushing of materials with higher hardness, and impact crusher is used for medium and fine crushing of materials with lower hardness. It can be flexibly selected according to the characteristics of the material. This combination can not only ensure production efficiency, but also meet the requirements of medium-sized mines for equipment stability and durability.

Large mines

Production requirements: Large mines have large outputs, and have extremely high requirements for the processing capacity, reliability and automation control level of the crusher. The equipment needs to be able to operate stably for a long time and have functions such as remote monitoring and fault diagnosis.

Material handling capacity: Daily handling capacity can reach thousands of tons or even tens of thousands of tons.

Site conditions: It has a vast operating site that can accommodate large equipment and has high requirements for equipment layout and logistics transportation.

Recommended crushers: Large jaw crushers, multi-cylinder hydraulic cone crushers and large impact crushers are the first choice for large mines. Large jaw crushers have strong processing capacity and can efficiently complete primary crushing tasks; multi-cylinder hydraulic cone crushers have the advantages of high automation, high crushing efficiency, and uniform product particle size, which are suitable for medium and fine crushing of materials with higher hardness; large impact crushers are suitable for medium and fine crushing of materials with lower hardness, which can ensure the particle shape of the finished product. In addition, large mines can also consider using large fixed production lines or large mobile crushing stations with integrated crushing and screening to improve production efficiency and automation level.

Previous: SMP Crusher

Next: SMP Crusher

Does the brand of the crusher matter?

Does the brand of the crusher matter? Is the brand and price of the crusher proportional?

Is the brand and price of the crusher proportional? With an investment of 180 million yuan, Liming Heavy Industry enables Henan to build an environmentally friendly sand and gravel base with an annual output of 6.5 million tons

With an investment of 180 million yuan, Liming Heavy Industry enables Henan to build an environmentally friendly sand and gravel base with an annual output of 6.5 million tons With an investment of 230 million yuan, Liming Heavy Industry helps Jiangxi build an intelligent sand and gravel comprehensive park with an annual output of 8 million tons

With an investment of 230 million yuan, Liming Heavy Industry helps Jiangxi build an intelligent sand and gravel comprehensive park with an annual output of 8 million tons With an investment of 310 million yuan, Liming Heavy Industry enables Zhejiang to build a smart sand and gravel industrial park with an annual output of 9.5 million tons

With an investment of 310 million yuan, Liming Heavy Industry enables Zhejiang to build a smart sand and gravel industrial park with an annual output of 9.5 million tons Does the brand of the crusher matter?

Does the brand of the crusher matter? Is the brand and price of the crusher proportional?

Is the brand and price of the crusher proportional? With an investment of 180 million yuan, Liming Heavy Industry enables Henan to build an environmentally friendly sand and gravel base with an annual output of 6.5 million tons

With an investment of 180 million yuan, Liming Heavy Industry enables Henan to build an environmentally friendly sand and gravel base with an annual output of 6.5 million tons With an investment of 230 million yuan, Liming Heavy Industry helps Jiangxi build an intelligent sand and gravel comprehensive park with an annual output of 8 million tons

With an investment of 230 million yuan, Liming Heavy Industry helps Jiangxi build an intelligent sand and gravel comprehensive park with an annual output of 8 million tons With an investment of 310 million yuan, Liming Heavy Industry enables Zhejiang to build a smart sand and gravel industrial park with an annual output of 9.5 million tons

With an investment of 310 million yuan, Liming Heavy Industry enables Zhejiang to build a smart sand and gravel industrial park with an annual output of 9.5 million tons