With the integration and transformation and upgrading of resources in the sand and gravel industry, the annual production capacity of sand and gravel mines has increased from hundreds of thousands of tons and millions of tons in previous years to tens

With the integration and transformation and upgrading of resources in the sand and gravel industry, the annual production capacity of sand and gravel mines has increased from hundreds of thousands of tons and millions of tons in previous years to tens of millions of tons and even hundreds of millions of tons. A larger scale also means that the complexity of production line construction and production operation and maintenance has increased. For companies that are not very experienced, it is easy to encounter the following problems:

Click to consult to learn about the construction plan of sand and gravel production lines

A series of problems such as lack of guarantee of project construction period, substandard production capacity, frequent unplanned downtime, substandard aggregate quality and high production and operation costs.

In order to help customers eliminate these problems and help customers achieve commercial success, Liming Group combines its more than 30 years of rich experience in the field of crushing and screening to customize EPC (O) general contracting services for industry customers.

Liming EPC general contracting service advantages

Full life cycle service

● Liming EPC services cover the entire life cycle of the project from design to operation, which makes customers more worry-free.

Rich project experience

● Liming has participated in the compilation of many national and industry standards to ensure project compliance and reduce related risks.

● Liming has provided EPC services to many customers, and its rich experience can effectively ensure the successful implementation of the project.

● Liming has established a set of standardized production and operation and maintenance systems to ensure that the project can operate continuously and stably.

● Liming's professional production technology can effectively exert the efficiency of the production line, improve the quality of finished products, and enhance market competitiveness.

Achieve cost reduction and efficiency improvement

● Liming's strong and professional equipment R&D, manufacturing and process design capabilities can understand the overall situation, control details, optimize each process and each equipment with systematic thinking, solve bottlenecks and improve efficiency.

● Liming took the lead in successfully applying "traditional industry + Internet technology" to the field of crushing and screening, which can help customers achieve digital intelligent transformation, thereby achieving the goal of saving costs and improving operational efficiency.

High-quality after-sales service

● Liming has a professional technical service team and a complete after-sales service system to ensure service efficiency.

● Liming provides customers with professional operator training to improve customers' production management capabilities.

● Liming's self-built casting plant has been successfully put into production, which can well meet the demand for spare parts supply; at the same time, Liming has equipped spare parts warehouses for major customers in some areas to cooperate with customers' production plans and fully guarantee customers' production continuity.

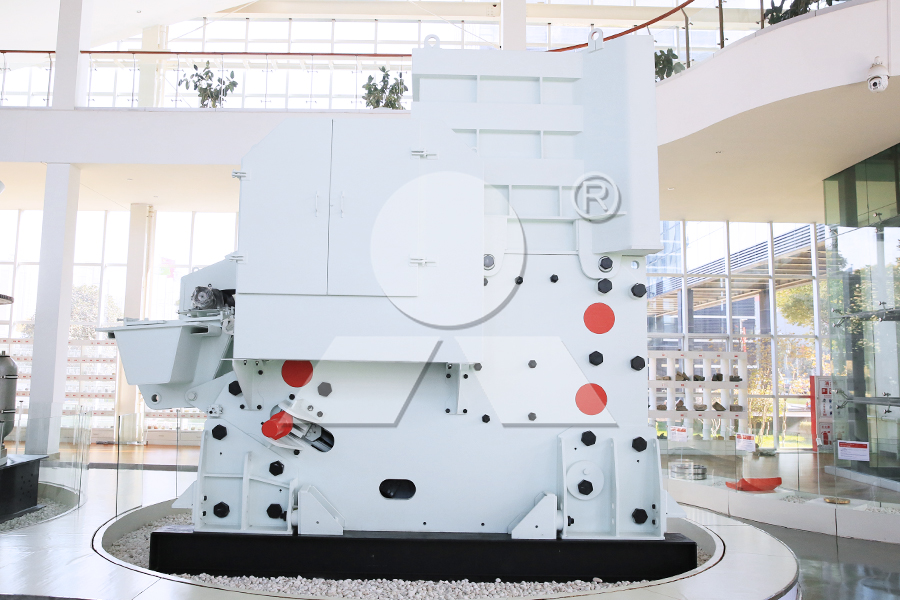

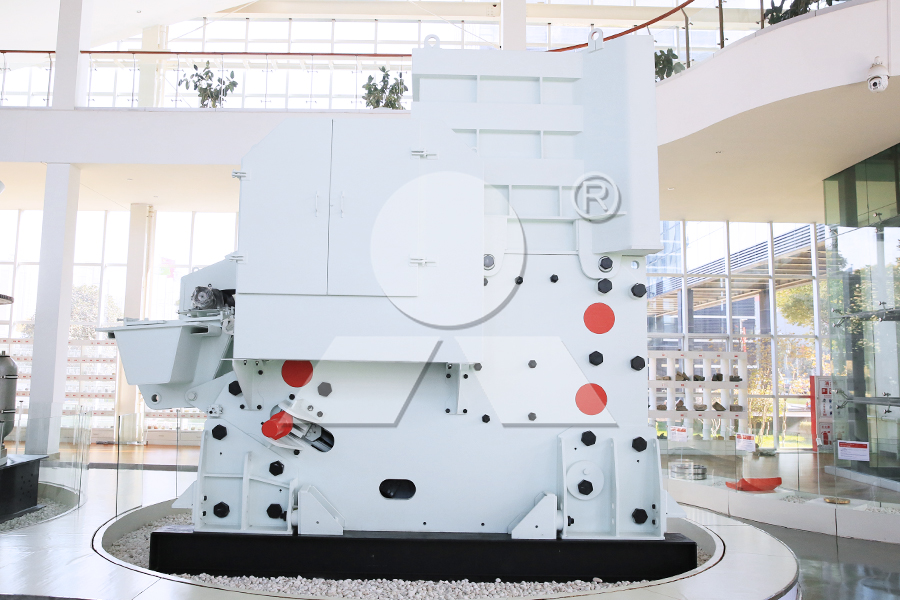

Previous: SMP Crusher

Next: SMP Crusher

With the integration and transformation and upgrading of resources in the sand and gravel industry, the annual production capacity of sand and gravel mines has increased from hundreds of thousands of tons and millions of tons in previous years to tens

With the integration and transformation and upgrading of resources in the sand and gravel industry, the annual production capacity of sand and gravel mines has increased from hundreds of thousands of tons and millions of tons in previous years to tens of millions of tons and even hundreds of millions of tons. A larger scale also means that the complexity of production line construction and production operation and maintenance has increased. For companies that are not very experienced, it is easy to encounter the following problems:

Click to consult to learn about the construction plan of sand and gravel production lines

A series of problems such as lack of guarantee of project construction period, substandard production capacity, frequent unplanned downtime, substandard aggregate quality and high production and operation costs.

In order to help customers eliminate these problems and help customers achieve commercial success, Liming Group combines its more than 30 years of rich experience in the field of crushing and screening to customize EPC (O) general contracting services for industry customers.

Liming EPC general contracting service advantages

Full life cycle service

● Liming EPC services cover the entire life cycle of the project from design to operation, which makes customers more worry-free.

Rich project experience

● Liming has participated in the compilation of many national and industry standards to ensure project compliance and reduce related risks.

● Liming has provided EPC services to many customers, and its rich experience can effectively ensure the successful implementation of the project.

● Liming has established a set of standardized production and operation and maintenance systems to ensure that the project can operate continuously and stably.

● Liming's professional production technology can effectively exert the efficiency of the production line, improve the quality of finished products, and enhance market competitiveness.

Achieve cost reduction and efficiency improvement

● Liming's strong and professional equipment R&D, manufacturing and process design capabilities can understand the overall situation, control details, optimize each process and each equipment with systematic thinking, solve bottlenecks and improve efficiency.

● Liming took the lead in successfully applying "traditional industry + Internet technology" to the field of crushing and screening, which can help customers achieve digital intelligent transformation, thereby achieving the goal of saving costs and improving operational efficiency.

High-quality after-sales service

● Liming has a professional technical service team and a complete after-sales service system to ensure service efficiency.

● Liming provides customers with professional operator training to improve customers' production management capabilities.

● Liming's self-built casting plant has been successfully put into production, which can well meet the demand for spare parts supply; at the same time, Liming has equipped spare parts warehouses for major customers in some areas to cooperate with customers' production plans and fully guarantee customers' production continuity.

Previous: SMP Crusher

Next: SMP Crusher

What are the factors affecting the price of stone factory production equipment?

What are the factors affecting the price of stone factory production equipment? What are the new sand making machines with an output of 500 tons per hour and how much do they cost?

What are the new sand making machines with an output of 500 tons per hour and how much do they cost? Mobile Stone Crusher Equipment Price

Mobile Stone Crusher Equipment Price How to configure the equipment of 1000 tons per hour gravel production line and how much does it cost

How to configure the equipment of 1000 tons per hour gravel production line and how much does it cost Recommendation and quotation analysis of crusher equipment for large sand and gravel plants

Recommendation and quotation analysis of crusher equipment for large sand and gravel plants What are the factors affecting the price of stone factory production equipment?

What are the factors affecting the price of stone factory production equipment? What are the new sand making machines with an output of 500 tons per hour and how much do they cost?

What are the new sand making machines with an output of 500 tons per hour and how much do they cost? Mobile Stone Crusher Equipment Price

Mobile Stone Crusher Equipment Price How to configure the equipment of 1000 tons per hour gravel production line and how much does it cost

How to configure the equipment of 1000 tons per hour gravel production line and how much does it cost Recommendation and quotation analysis of crusher equipment for large sand and gravel plants

Recommendation and quotation analysis of crusher equipment for large sand and gravel plants