In numerous industries such as metallurgy, mining, building materials, chemicals, and ceramics, material crushing is a crucial process. Due to the diverse properties of materials, selecting the appropriate crusher is essential. The crushing process is

In numerous industries such as metallurgy, mining, building materials, chemicals, and ceramics, material crushing is a crucial process. Due to the diverse properties of materials, selecting the appropriate crusher is essential. The crushing process is usually divided into coarse crushing, medium crushing, and fine crushing, with a wide variety of corresponding crushing equipment. This article will reveal the scientific approach to crusher selection.

Learn more about crushing and sand-making equipment

Types and characteristics of crushers

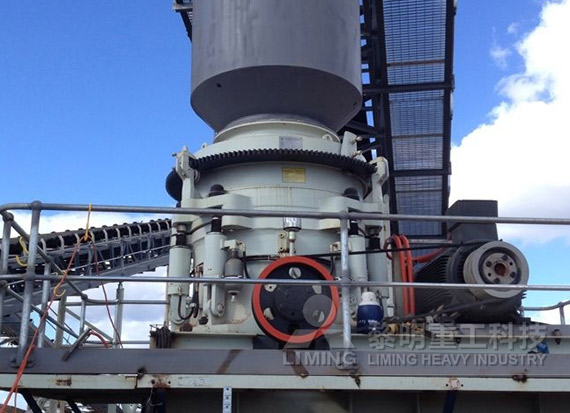

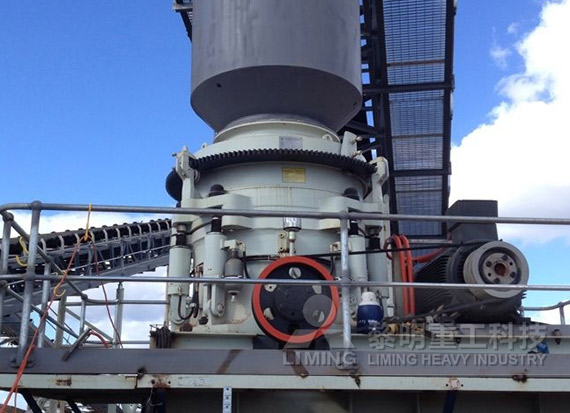

In daily production, common crushers include jaw crushers, cone crushers, impact crushers (also known as sand-making machines), impact crushers, and hammer crushers. Choosing the right crusher can not only effectively reduce crushing time and material waste but also reduce equipment wear and tear.

Five basic forms of mechanical crushing

Compression crushing: Materials are crushed under slowly increasing pressure between two working surfaces.

Splitting crushing: The ore is crushed by compression from sharp edges, splitting along the direction of the pressure line.

Fracture crushing: Large pieces of ore are broken into smaller pieces under bending stress.

Grinding crushing: The ore moves relative to the moving working surface and is crushed by pressure and shear forces.

Impact crushing: Materials are efficiently crushed by a large impact force, resulting in a high crushing ratio and low energy consumption.

Factors to consider when choosing a crusher

Material type and hardness: Mohs hardness is a key indicator of material hardness; the higher the hardness, the more difficult the crushing.

Material moisture content: Excessive moisture content can cause material clumping, affecting crushing efficiency and discharge speed.

Ore cleavage degree: Ores with well-developed cleavage are easy to crush, and the crusher's productivity is correspondingly higher.

Input and output particle size: The input and output particle size determine the required crusher model and crushing level.

Construction site: The site area and equipment placement also affect the choice of crusher.

Production requirements: Production requirements determine the specifications of the crushing equipment, which in turn affects investment and output.

In summary, the scientific selection of a crusher requires comprehensive consideration of material properties, crushing requirements, construction site, and production needs. Only by choosing the right equipment can efficient, safe, and environmentally friendly production be ensured.

Previous: SMP Crusher

Next: SMP Crusher

In numerous industries such as metallurgy, mining, building materials, chemicals, and ceramics, material crushing is a crucial process. Due to the diverse properties of materials, selecting the appropriate crusher is essential. The crushing process is

In numerous industries such as metallurgy, mining, building materials, chemicals, and ceramics, material crushing is a crucial process. Due to the diverse properties of materials, selecting the appropriate crusher is essential. The crushing process is usually divided into coarse crushing, medium crushing, and fine crushing, with a wide variety of corresponding crushing equipment. This article will reveal the scientific approach to crusher selection.

Learn more about crushing and sand-making equipment

Types and characteristics of crushers

In daily production, common crushers include jaw crushers, cone crushers, impact crushers (also known as sand-making machines), impact crushers, and hammer crushers. Choosing the right crusher can not only effectively reduce crushing time and material waste but also reduce equipment wear and tear.

Five basic forms of mechanical crushing

Compression crushing: Materials are crushed under slowly increasing pressure between two working surfaces.

Splitting crushing: The ore is crushed by compression from sharp edges, splitting along the direction of the pressure line.

Fracture crushing: Large pieces of ore are broken into smaller pieces under bending stress.

Grinding crushing: The ore moves relative to the moving working surface and is crushed by pressure and shear forces.

Impact crushing: Materials are efficiently crushed by a large impact force, resulting in a high crushing ratio and low energy consumption.

Factors to consider when choosing a crusher

Material type and hardness: Mohs hardness is a key indicator of material hardness; the higher the hardness, the more difficult the crushing.

Material moisture content: Excessive moisture content can cause material clumping, affecting crushing efficiency and discharge speed.

Ore cleavage degree: Ores with well-developed cleavage are easy to crush, and the crusher's productivity is correspondingly higher.

Input and output particle size: The input and output particle size determine the required crusher model and crushing level.

Construction site: The site area and equipment placement also affect the choice of crusher.

Production requirements: Production requirements determine the specifications of the crushing equipment, which in turn affects investment and output.

In summary, the scientific selection of a crusher requires comprehensive consideration of material properties, crushing requirements, construction site, and production needs. Only by choosing the right equipment can efficient, safe, and environmentally friendly production be ensured.

Previous: SMP Crusher

Next: SMP Crusher

How to configure a stone crushing production line with a capacity of 300-400 tons per hour, and what is the approximate cost?

How to configure a stone crushing production line with a capacity of 300-400 tons per hour, and what is the approximate cost? How to configure a stone crushing production line with a capacity of 300-400 tons per hour, and what is the approximate cost?

How to configure a stone crushing production line with a capacity of 300-400 tons per hour, and what is the approximate cost? Why did China Power Construction Guangdong choose to cooperate with Shibang for its 30 million tons per year sand and aggregate production project?

Why did China Power Construction Guangdong choose to cooperate with Shibang for its 30 million tons per year sand and aggregate production project? What equipment is needed for a limestone aggregate production line with a capacity of 500 tons per hour?

What equipment is needed for a limestone aggregate production line with a capacity of 500 tons per hour? River pebble sand production line configuration plan

River pebble sand production line configuration plan How to configure a stone crushing production line with a capacity of 300-400 tons per hour, and what is the approximate cost?

How to configure a stone crushing production line with a capacity of 300-400 tons per hour, and what is the approximate cost? How to configure a stone crushing production line with a capacity of 300-400 tons per hour, and what is the approximate cost?

How to configure a stone crushing production line with a capacity of 300-400 tons per hour, and what is the approximate cost? Why did China Power Construction Guangdong choose to cooperate with Shibang for its 30 million tons per year sand and aggregate production project?

Why did China Power Construction Guangdong choose to cooperate with Shibang for its 30 million tons per year sand and aggregate production project? What equipment is needed for a limestone aggregate production line with a capacity of 500 tons per hour?

What equipment is needed for a limestone aggregate production line with a capacity of 500 tons per hour? River pebble sand production line configuration plan

River pebble sand production line configuration plan