Granite is an intrusive rock in the magmatic rocks, which is the most common type of rock in this category, and is mostly light flesh-red, light gray, and off-white. Granite can be further named according to the type of dark mineral. The Mohs hardness

Granite is an intrusive rock in the magmatic rocks, which is the most common type of rock in this category, and is mostly light flesh-red, light gray, and off-white. Granite can be further named according to the type of dark mineral. The Mohs hardness is generally 6-7, which makes it a medium-hard stone. Granite crushed stone due to its hard texture, difficult to be eroded by acid and alkali or weathering, granite high compressive strength, low crushing value, strong corrosion resistance, asphalt adhesion and other characteristics of the commonly used building stone, due to its porous and hard characteristics, will be mixed in the concrete, you can make the concrete weight reduction, without losing the solid, while sound insulation, heat insulation and other advantages, to become a high-rise building of lightweight concrete High quality aggregate. Granite stone can be used to make mortar and concrete respectively according to different stone specifications, 1-2, 2-4, 4-8 are very common stone specifications. China's infrastructure construction can not be stopped, the domestic granite stone market has been extremely hot.

SMPCRUSHER adopts a unique processing technology in the production of granite, which makes the utilization rate of granite more than 95%. Reduce the waste of raw materials and greatly increase the production capacity.

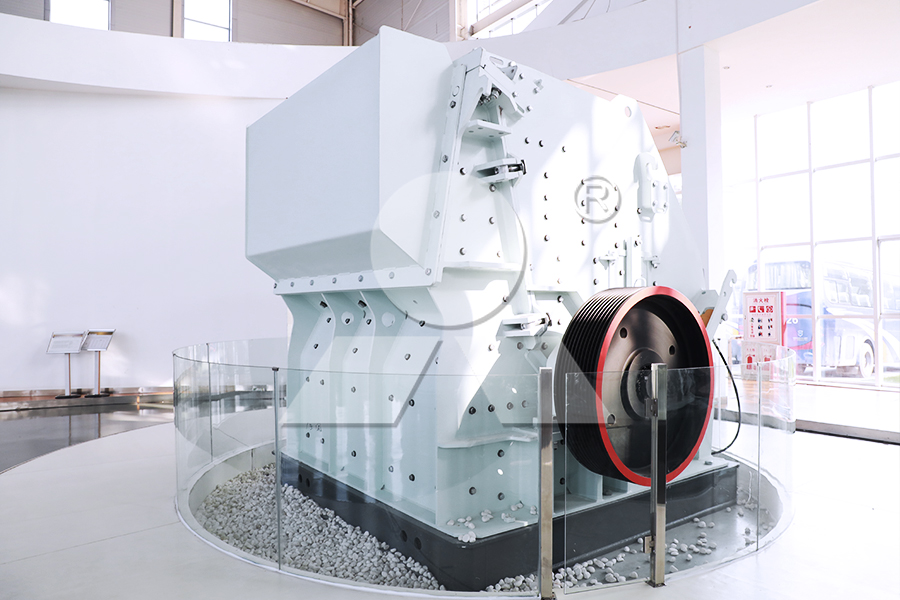

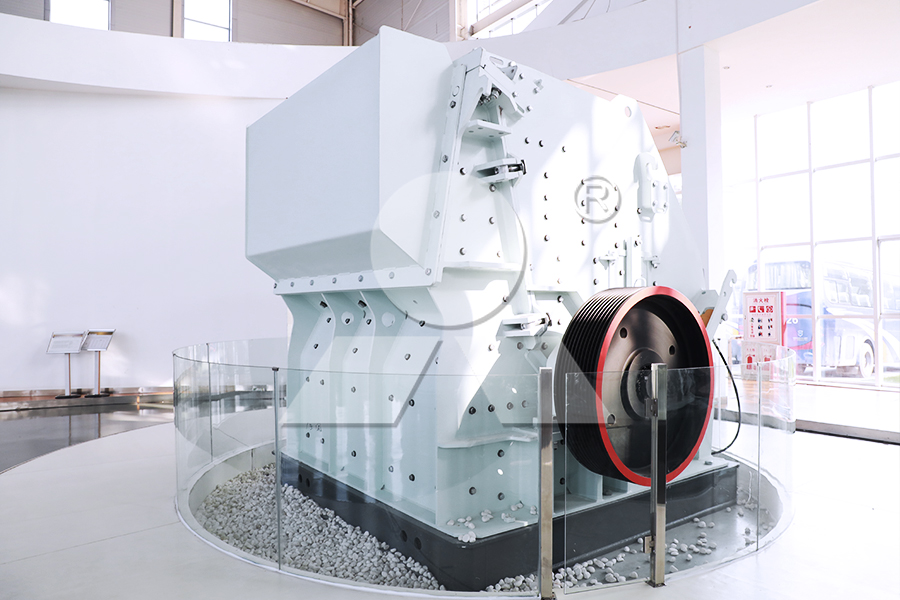

SMPCRUSHER Mining Machinery Co., Ltd. in the granite crushing production process can generally choose two-stage crushing production process, the first stage of the choice of jaw crusher, granite materials are first sent to the jaw crusher through the vibratory feeder uniformly coarse crushing process, the second stage of the choice of the impact crusher, and then by the belt conveyor continuous, quantitatively after the coarse crushing materials into the impact crusher for further After crushing; the finely crushed marble/granite particles will be screened into different grades by vibrating screen, which can use circular vibrating screen to screen out the different specifications of 1-2, 2-4, 4-8 stones, and the materials that meet the requirements will be sent to sand making machine to make sand, while the unqualified materials will be re-sent back to the upper level to continue crushing; finally, the sand out of the sand making machine has to go through the sand washing machine to clean and remove impurities, and then the high-quality finished products can be obtained.

SMPCRUSHER Mining Machine Jaw Crusher with a feed size of 125mm~750mm is the preferred equipment for primary crushing.

1. Large handling capacity and even particle size.

The crushing cavity is deep and without dead zone, which improves the feeding capacity and output, the crushing ratio is large, and the product size is even.

2. Low maintenance cost, safe and reliable.

Gasket type discharge opening adjustment device is reliable and convenient, with a wide range of adjustment, increasing the flexibility of the equipment, safe and reliable lubrication system, easy replacement of parts, and low maintenance workload.

3、Low operation cost, energy-saving system.

Simple structure, reliable work, low operating costs, single machine energy saving 15% to 30%, system energy saving more than double.

4.Specialized wearing parts, long service life.

The jaw plate is made of ZGMN13 manganese steel which is more solid and wear-resistant, the main body of the elbow plate made of HT200 cast iron is more comprehensively protected, and the body is lubricated by yellow oil, which is more convenient for maintenance.

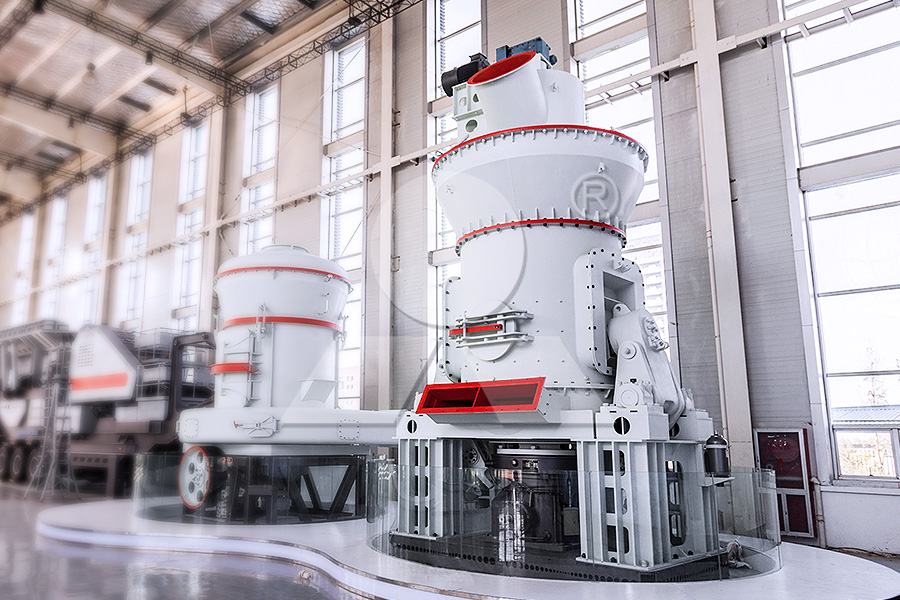

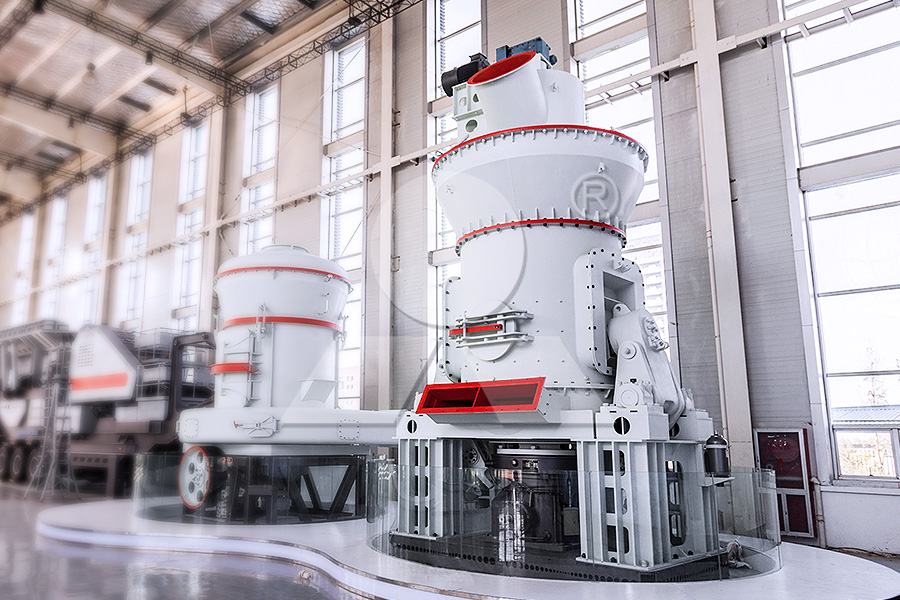

SMPCRUSHER professional crusher manufacturer, General Mining Machinery 20 years focus on the production and manufacture of mining equipment, the continuous introduction of foreign advanced technology fusion research and development, the production of a set of company-specific quality products. General Raymond Mill, Europe version of the mill, ultra-fine mill, high-pressure mill is exported to domestic and foreign and a number of enterprises signed a contract to purchase machines, annual sales volume reached more than 500 units.

Previous: SMP Crusher

Next: SMP Crusher

Granite is an intrusive rock in the magmatic rocks, which is the most common type of rock in this category, and is mostly light flesh-red, light gray, and off-white. Granite can be further named according to the type of dark mineral. The Mohs hardness

Granite is an intrusive rock in the magmatic rocks, which is the most common type of rock in this category, and is mostly light flesh-red, light gray, and off-white. Granite can be further named according to the type of dark mineral. The Mohs hardness is generally 6-7, which makes it a medium-hard stone. Granite crushed stone due to its hard texture, difficult to be eroded by acid and alkali or weathering, granite high compressive strength, low crushing value, strong corrosion resistance, asphalt adhesion and other characteristics of the commonly used building stone, due to its porous and hard characteristics, will be mixed in the concrete, you can make the concrete weight reduction, without losing the solid, while sound insulation, heat insulation and other advantages, to become a high-rise building of lightweight concrete High quality aggregate. Granite stone can be used to make mortar and concrete respectively according to different stone specifications, 1-2, 2-4, 4-8 are very common stone specifications. China's infrastructure construction can not be stopped, the domestic granite stone market has been extremely hot.

SMPCRUSHER adopts a unique processing technology in the production of granite, which makes the utilization rate of granite more than 95%. Reduce the waste of raw materials and greatly increase the production capacity.

SMPCRUSHER Mining Machinery Co., Ltd. in the granite crushing production process can generally choose two-stage crushing production process, the first stage of the choice of jaw crusher, granite materials are first sent to the jaw crusher through the vibratory feeder uniformly coarse crushing process, the second stage of the choice of the impact crusher, and then by the belt conveyor continuous, quantitatively after the coarse crushing materials into the impact crusher for further After crushing; the finely crushed marble/granite particles will be screened into different grades by vibrating screen, which can use circular vibrating screen to screen out the different specifications of 1-2, 2-4, 4-8 stones, and the materials that meet the requirements will be sent to sand making machine to make sand, while the unqualified materials will be re-sent back to the upper level to continue crushing; finally, the sand out of the sand making machine has to go through the sand washing machine to clean and remove impurities, and then the high-quality finished products can be obtained.

SMPCRUSHER Mining Machine Jaw Crusher with a feed size of 125mm~750mm is the preferred equipment for primary crushing.

1. Large handling capacity and even particle size.

The crushing cavity is deep and without dead zone, which improves the feeding capacity and output, the crushing ratio is large, and the product size is even.

2. Low maintenance cost, safe and reliable.

Gasket type discharge opening adjustment device is reliable and convenient, with a wide range of adjustment, increasing the flexibility of the equipment, safe and reliable lubrication system, easy replacement of parts, and low maintenance workload.

3、Low operation cost, energy-saving system.

Simple structure, reliable work, low operating costs, single machine energy saving 15% to 30%, system energy saving more than double.

4.Specialized wearing parts, long service life.

The jaw plate is made of ZGMN13 manganese steel which is more solid and wear-resistant, the main body of the elbow plate made of HT200 cast iron is more comprehensively protected, and the body is lubricated by yellow oil, which is more convenient for maintenance.

SMPCRUSHER professional crusher manufacturer, General Mining Machinery 20 years focus on the production and manufacture of mining equipment, the continuous introduction of foreign advanced technology fusion research and development, the production of a set of company-specific quality products. General Raymond Mill, Europe version of the mill, ultra-fine mill, high-pressure mill is exported to domestic and foreign and a number of enterprises signed a contract to purchase machines, annual sales volume reached more than 500 units.

Previous: SMP Crusher

Next: SMP Crusher

Industrial milling trend of environmental protection and large-scale

Industrial milling trend of environmental protection and large-scale Construction waste disposal industry booms thanks to mobile crushing plant

Construction waste disposal industry booms thanks to mobile crushing plant How recycled glass is handled to reap more benefits

How recycled glass is handled to reap more benefits Sand and gravel prices soaring, sand and gravel aggregate production line imminent

Sand and gravel prices soaring, sand and gravel aggregate production line imminent Can kaolin mill process 200 mesh

Can kaolin mill process 200 mesh Industrial milling trend of environmental protection and large-scale

Industrial milling trend of environmental protection and large-scale Construction waste disposal industry booms thanks to mobile crushing plant

Construction waste disposal industry booms thanks to mobile crushing plant How recycled glass is handled to reap more benefits

How recycled glass is handled to reap more benefits Sand and gravel prices soaring, sand and gravel aggregate production line imminent

Sand and gravel prices soaring, sand and gravel aggregate production line imminent Can kaolin mill process 200 mesh

Can kaolin mill process 200 mesh