Brick slag crushers are divided into fixed and mobile types, each with its own advantages and disadvantages. Fixed types are suitable for large-scale production, while mobile types are suitable for short-term or frequently relocated projects. When choo

Brick slag crushers are divided into fixed and mobile types, each with its own advantages and disadvantages. Fixed types are suitable for large-scale production, while mobile types are suitable for short-term or frequently relocated projects. When choosing, you need to consider demand, performance, price and maintenance costs. Brick slag has high recycling value and can be processed into building materials or road foundations.

In the field of brick slag crushing, choosing the right equipment is crucial. Currently, there are two main types of crushers on the market: fixed and mobile, each with its own advantages and suitable for different scenarios. This article will explore the characteristics, advantages and prices of these two types of equipment in depth to help you make a wise choice.

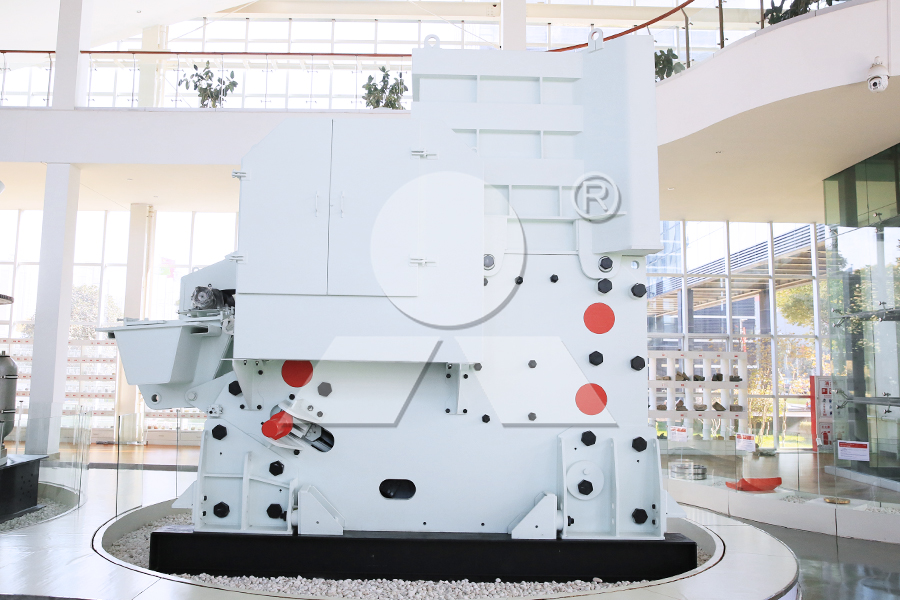

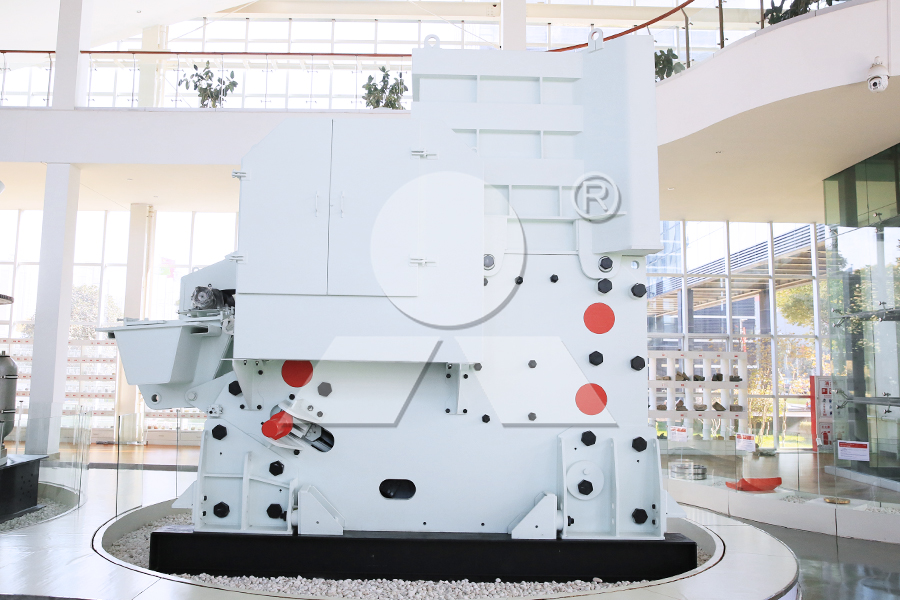

Details of equipment for recycling brick slag construction waste

Fixed brick slag crusher

Features and advantages:

Widely used: can handle iron ore, construction waste, etc., suitable for multiple industries such as construction and mining.

Various models: including jaw, cone, impact and other types to meet different production needs.

Stable performance: compression-resistant and wear-resistant materials give it a long service life.

Disadvantages:

It needs to be installed on a concrete foundation, with high transportation costs and complex installation.

Price range:

Small equipment ranges from a few thousand yuan to tens of thousands of yuan, and large high-performance equipment can reach hundreds of thousands of yuan.

Mobile brick slag crusher

Features and advantages:

Flexible mobility: The vehicle-mounted system design can quickly reach the work site.

Nearby processing: Save transportation costs and avoid secondary pollution.

High automation: Equipped with a PLC control system, real-time monitoring of equipment status, and reduced labor costs.

Disadvantages:

Relatively high price and maintenance cost, limited output value, not suitable for high-yield demand.

Price range:

Small equipment ranges from tens of thousands to hundreds of thousands of yuan, and large high-end equipment can cost more than hundreds of thousands of yuan.

Selection suggestions

When choosing equipment, it should be based on specific needs. If it is a large fixed site, it is recommended to choose a fixed crusher to meet large-scale production needs; if it is a short-term or frequently changing location project, a mobile crusher is more suitable, which can be quickly put into production and save transportation costs.

Brick slag reuse

Brick slag is not only a waste, but also has a high reuse value. Through crushing, screening and other processes, brick slag can be processed into sand and gravel aggregates for the production of building materials such as concrete and mortar, or for paving road foundations.

Conclusion

Whether you choose a fixed or mobile brick slag crusher, you must combine actual needs, comprehensively consider equipment performance, price and maintenance costs, and make a wise choice that suits you.

Previous: SMP Crusher

Next: SMP Crusher

Brick slag crushers are divided into fixed and mobile types, each with its own advantages and disadvantages. Fixed types are suitable for large-scale production, while mobile types are suitable for short-term or frequently relocated projects. When choo

Brick slag crushers are divided into fixed and mobile types, each with its own advantages and disadvantages. Fixed types are suitable for large-scale production, while mobile types are suitable for short-term or frequently relocated projects. When choosing, you need to consider demand, performance, price and maintenance costs. Brick slag has high recycling value and can be processed into building materials or road foundations.

In the field of brick slag crushing, choosing the right equipment is crucial. Currently, there are two main types of crushers on the market: fixed and mobile, each with its own advantages and suitable for different scenarios. This article will explore the characteristics, advantages and prices of these two types of equipment in depth to help you make a wise choice.

Details of equipment for recycling brick slag construction waste

Fixed brick slag crusher

Features and advantages:

Widely used: can handle iron ore, construction waste, etc., suitable for multiple industries such as construction and mining.

Various models: including jaw, cone, impact and other types to meet different production needs.

Stable performance: compression-resistant and wear-resistant materials give it a long service life.

Disadvantages:

It needs to be installed on a concrete foundation, with high transportation costs and complex installation.

Price range:

Small equipment ranges from a few thousand yuan to tens of thousands of yuan, and large high-performance equipment can reach hundreds of thousands of yuan.

Mobile brick slag crusher

Features and advantages:

Flexible mobility: The vehicle-mounted system design can quickly reach the work site.

Nearby processing: Save transportation costs and avoid secondary pollution.

High automation: Equipped with a PLC control system, real-time monitoring of equipment status, and reduced labor costs.

Disadvantages:

Relatively high price and maintenance cost, limited output value, not suitable for high-yield demand.

Price range:

Small equipment ranges from tens of thousands to hundreds of thousands of yuan, and large high-end equipment can cost more than hundreds of thousands of yuan.

Selection suggestions

When choosing equipment, it should be based on specific needs. If it is a large fixed site, it is recommended to choose a fixed crusher to meet large-scale production needs; if it is a short-term or frequently changing location project, a mobile crusher is more suitable, which can be quickly put into production and save transportation costs.

Brick slag reuse

Brick slag is not only a waste, but also has a high reuse value. Through crushing, screening and other processes, brick slag can be processed into sand and gravel aggregates for the production of building materials such as concrete and mortar, or for paving road foundations.

Conclusion

Whether you choose a fixed or mobile brick slag crusher, you must combine actual needs, comprehensively consider equipment performance, price and maintenance costs, and make a wise choice that suits you.

Previous: SMP Crusher

Next: SMP Crusher

600 tons per hour gravel production line

600 tons per hour gravel production line The role of mobile screening equipment in sand and gravel aggregate production

The role of mobile screening equipment in sand and gravel aggregate production Calcite crushing equipment, what equipment is needed for calcite ore crushing

Calcite crushing equipment, what equipment is needed for calcite ore crushing What are the 1000 tons per hour calcite crushing equipment?

What are the 1000 tons per hour calcite crushing equipment? How to judge the environmental performance of river pebble aggregate sand making equipment production line

How to judge the environmental performance of river pebble aggregate sand making equipment production line 600 tons per hour gravel production line

600 tons per hour gravel production line The role of mobile screening equipment in sand and gravel aggregate production

The role of mobile screening equipment in sand and gravel aggregate production Calcite crushing equipment, what equipment is needed for calcite ore crushing

Calcite crushing equipment, what equipment is needed for calcite ore crushing What are the 1000 tons per hour calcite crushing equipment?

What are the 1000 tons per hour calcite crushing equipment? How to judge the environmental performance of river pebble aggregate sand making equipment production line

How to judge the environmental performance of river pebble aggregate sand making equipment production line