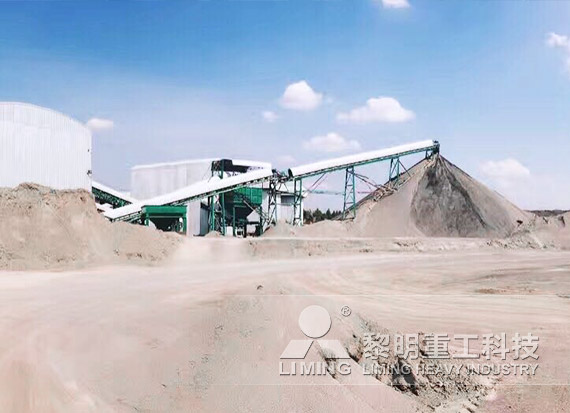

Shibang Group's 800 tons per hour basalt crushing and sand making production line configuration example:Project size: 800 tons per hourProcessing material: BasaltFinished product size: 0-3-5-

Shibang Group's 800 tons per hour basalt crushing and sand making production line configuration example:

Project size: 800 tons per hour

Processing material: Basalt

Finished product size: 0-3-5-10-15-26.5mm

Equipment configuration: Jaw crusher + single-cylinder hydraulic cone crusher + multi-cylinder hydraulic cone crusher + vertical shaft impact crusher + vibrating screen + feeder

Processing process: Dry process

Click here to inquire about crushing and sand making production line configuration options and pricing.

The production line utilizes an efficient three-stage, one-crushing process, encompassing primary crushing, secondary crushing, and fine screening, accurately producing high-quality fine sand of 0-3mm. This flexible process design allows for rapid adjustment of finished product size in response to market demand. Leveraging a mature technical system, the aggregate produced not only easily meets international standards but also meets the high standards required for road construction, ensuring superior product quality and broad market adaptability.

The main equipment selected is SBM's advanced jaw crusher, single-cylinder hydraulic cone crusher, multi-cylinder hydraulic cone crusher, and vertical shaft impact crusher. These crushers simultaneously produce sand and shape it, meeting the customer's demand for high-quality aggregate.

The production process utilizes a dry process, operating in a fully enclosed plant. A micro-mist dust suppression system is installed in dust-prone areas, effectively reducing dust emissions and strictly controlling environmental emissions. This fully complies with environmental emission standards, achieving green and efficient production.

Previous: SMP Crusher

Next: SMP Crusher

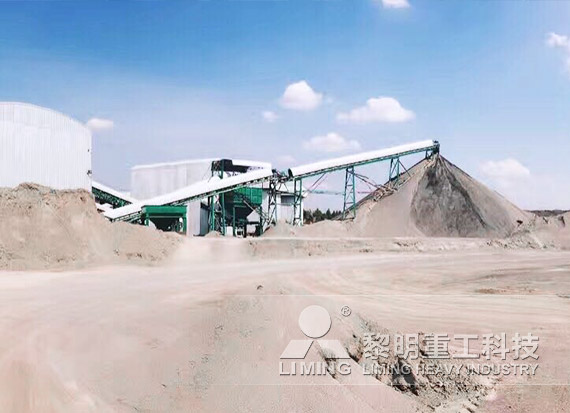

Shibang Group's 800 tons per hour basalt crushing and sand making production line configuration example:Project size: 800 tons per hourProcessing material: BasaltFinished product size: 0-3-5-

Shibang Group's 800 tons per hour basalt crushing and sand making production line configuration example:

Project size: 800 tons per hour

Processing material: Basalt

Finished product size: 0-3-5-10-15-26.5mm

Equipment configuration: Jaw crusher + single-cylinder hydraulic cone crusher + multi-cylinder hydraulic cone crusher + vertical shaft impact crusher + vibrating screen + feeder

Processing process: Dry process

Click here to inquire about crushing and sand making production line configuration options and pricing.

The production line utilizes an efficient three-stage, one-crushing process, encompassing primary crushing, secondary crushing, and fine screening, accurately producing high-quality fine sand of 0-3mm. This flexible process design allows for rapid adjustment of finished product size in response to market demand. Leveraging a mature technical system, the aggregate produced not only easily meets international standards but also meets the high standards required for road construction, ensuring superior product quality and broad market adaptability.

The main equipment selected is SBM's advanced jaw crusher, single-cylinder hydraulic cone crusher, multi-cylinder hydraulic cone crusher, and vertical shaft impact crusher. These crushers simultaneously produce sand and shape it, meeting the customer's demand for high-quality aggregate.

The production process utilizes a dry process, operating in a fully enclosed plant. A micro-mist dust suppression system is installed in dust-prone areas, effectively reducing dust emissions and strictly controlling environmental emissions. This fully complies with environmental emission standards, achieving green and efficient production.

Previous: SMP Crusher

Next: SMP Crusher

Coal gangue crusher full set of equipment price

Coal gangue crusher full set of equipment price What are the stone crushing machinery and equipment

What are the stone crushing machinery and equipment How much is a set of 3000 tons of sand making machine (Nissan)

How much is a set of 3000 tons of sand making machine (Nissan) What are the reasons for the sudden shutdown of the gravel sand making machine during operation?

What are the reasons for the sudden shutdown of the gravel sand making machine during operation? What are the complete sets of sand making equipment

What are the complete sets of sand making equipment Coal gangue crusher full set of equipment price

Coal gangue crusher full set of equipment price What are the stone crushing machinery and equipment

What are the stone crushing machinery and equipment How much is a set of 3000 tons of sand making machine (Nissan)

How much is a set of 3000 tons of sand making machine (Nissan) What are the reasons for the sudden shutdown of the gravel sand making machine during operation?

What are the reasons for the sudden shutdown of the gravel sand making machine during operation? What are the complete sets of sand making equipment

What are the complete sets of sand making equipment