The configuration plan of the 2,000-ton sand and gravel production line is as follows:Finished product size: 0-5-10-20-31.5mmEquipment configuration: F5X1345 feeder, PEW jaw crusher, 2 HPT300 multi-cylinder hydraul

The configuration plan of the 2,000-ton sand and gravel production line is as follows:

Finished product size: 0-5-10-20-31.5mm

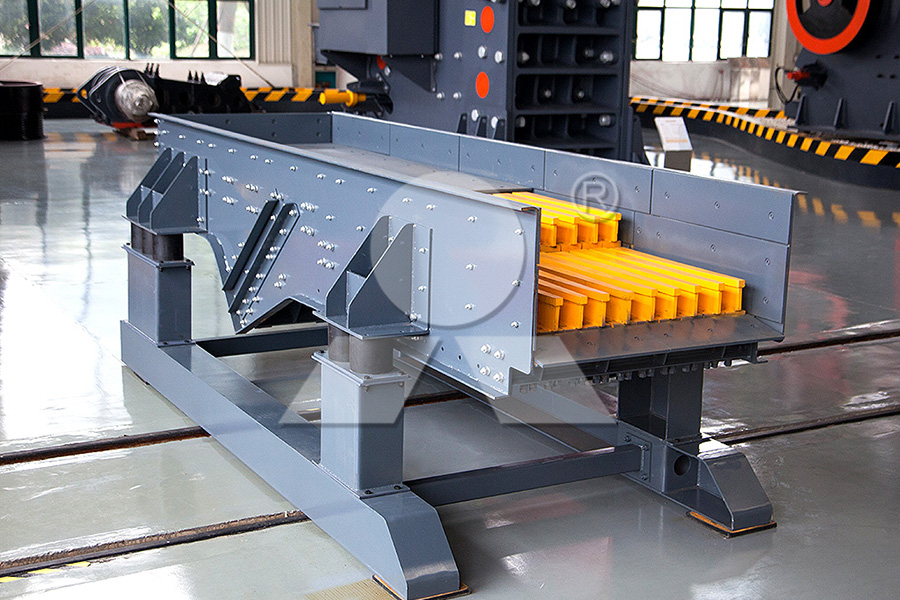

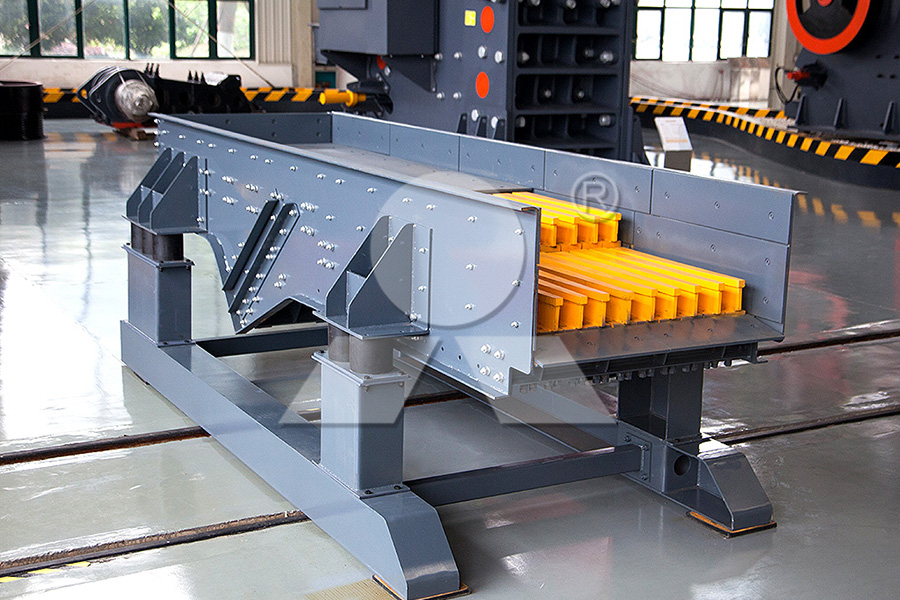

Equipment configuration: F5X1345 feeder, PEW jaw crusher, 2 HPT300 multi-cylinder hydraulic cone crushers, 2 S5X2460-2 vibrating screens, S5X2460-3 vibrating screen

Click here to consult the construction plan of the sand and gravel aggregate production line

The process flow chart is as follows:

After the granite material is blasted, it is first pre-screened by the F5X1345 feeder. Small materials are directly fed into the transfer bin of the cone crusher, while large materials need to be crushed by the jaw crusher before entering the bin. The transfer bin also supplies two HPT300 multi-cylinder hydraulic cone crushers for further crushing. The material produced by the cone crusher is then screened by two S5X2460-2 new vibrating screens, and the large materials will return to the cone crusher for re-crushing until a 31.5-40mm finished product is obtained. The remaining finished products are then screened by S5X2460-3, and finally four specifications of finished products of 0-5mm, 10mm, 20mm and 31.5mm are obtained.

Previous: SMP Crusher

Next: SMP Crusher

The configuration plan of the 2,000-ton sand and gravel production line is as follows:Finished product size: 0-5-10-20-31.5mmEquipment configuration: F5X1345 feeder, PEW jaw crusher, 2 HPT300 multi-cylinder hydraul

The configuration plan of the 2,000-ton sand and gravel production line is as follows:

Finished product size: 0-5-10-20-31.5mm

Equipment configuration: F5X1345 feeder, PEW jaw crusher, 2 HPT300 multi-cylinder hydraulic cone crushers, 2 S5X2460-2 vibrating screens, S5X2460-3 vibrating screen

Click here to consult the construction plan of the sand and gravel aggregate production line

The process flow chart is as follows:

After the granite material is blasted, it is first pre-screened by the F5X1345 feeder. Small materials are directly fed into the transfer bin of the cone crusher, while large materials need to be crushed by the jaw crusher before entering the bin. The transfer bin also supplies two HPT300 multi-cylinder hydraulic cone crushers for further crushing. The material produced by the cone crusher is then screened by two S5X2460-2 new vibrating screens, and the large materials will return to the cone crusher for re-crushing until a 31.5-40mm finished product is obtained. The remaining finished products are then screened by S5X2460-3, and finally four specifications of finished products of 0-5mm, 10mm, 20mm and 31.5mm are obtained.

Previous: SMP Crusher

Next: SMP Crusher

What are the machines for processing gold ore?

What are the machines for processing gold ore? Mobile construction waste crushing station - construction waste recycling equipment

Mobile construction waste crushing station - construction waste recycling equipment Melon Seed Slice Stone Production and Equipment Selection

Melon Seed Slice Stone Production and Equipment Selection How much is a 3000 cubic meter sand production line per day

How much is a 3000 cubic meter sand production line per day How to choose a 300 tons per hour mobile crushing station

How to choose a 300 tons per hour mobile crushing station What are the machines for processing gold ore?

What are the machines for processing gold ore? Mobile construction waste crushing station - construction waste recycling equipment

Mobile construction waste crushing station - construction waste recycling equipment Melon Seed Slice Stone Production and Equipment Selection

Melon Seed Slice Stone Production and Equipment Selection How much is a 3000 cubic meter sand production line per day

How much is a 3000 cubic meter sand production line per day How to choose a 300 tons per hour mobile crushing station

How to choose a 300 tons per hour mobile crushing station