Common stone production line equipment configurations include feeders, jaw crushers, impact crushers or cone crushers, sand making machines, circular vibrating screens, belt conveyors, centralized electronic control systems and other equipment. They ca

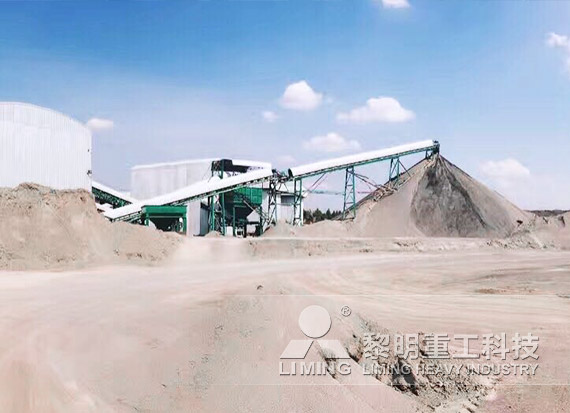

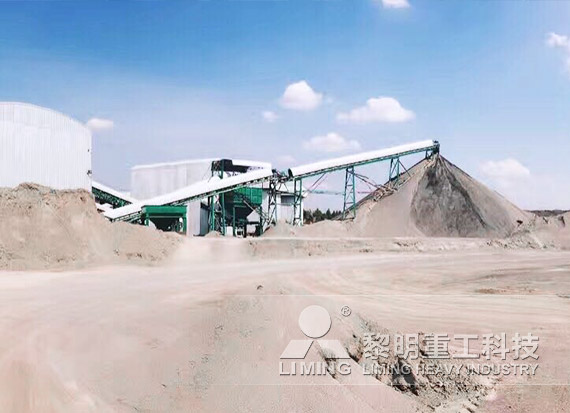

Common stone production line equipment configurations include feeders, jaw crushers, impact crushers or cone crushers, sand making machines, circular vibrating screens, belt conveyors, centralized electronic control systems and other equipment. They can crush rocks such as granite, limestone, gypsum and other rocks very well. So, how does a quarry configure a high-quality stone production line?

Click here to consult to learn about the construction plan of a stone production line

First, before selecting equipment, users need to understand their production needs clearly, such as what raw materials to crush, the size, hardness, humidity and other properties of the raw material particle size, how large the output is, the particle shape requirements, how many specifications are required, the hourly production requirements, how large the installation site is, etc.

Secondly, after clarifying the production needs, you can choose which process equipment to configure according to the budget. Taking the main crushing equipment as an example, there are many solutions to achieve stone crushing, some of which are of good quality, some are of high efficiency, and some are of low investment. Some can crush high-hardness materials, low-hardness materials, and materials with high moisture content. Some can only handle brittle materials, etc. If users want to save more money on investment, they need to reasonably configure according to the properties of their crushed materials and production requirements.

Then, auxiliary equipment such as feeding, screening, and conveying equipment can also save users a lot of investment and create high returns. The type and model of feeding equipment needs to be determined according to the stone mining capacity of the gravel plant and the production capacity of the primary crusher equipment; the type and quantity of screening equipment needs to be determined according to the production capacity of the fine crusher and the requirements of stone specifications; the type and length of conveying equipment needs to be determined according to the needs of the main equipment.

Previous: SMP Crusher

Next: SMP Crusher

Common stone production line equipment configurations include feeders, jaw crushers, impact crushers or cone crushers, sand making machines, circular vibrating screens, belt conveyors, centralized electronic control systems and other equipment. They ca

Common stone production line equipment configurations include feeders, jaw crushers, impact crushers or cone crushers, sand making machines, circular vibrating screens, belt conveyors, centralized electronic control systems and other equipment. They can crush rocks such as granite, limestone, gypsum and other rocks very well. So, how does a quarry configure a high-quality stone production line?

Click here to consult to learn about the construction plan of a stone production line

First, before selecting equipment, users need to understand their production needs clearly, such as what raw materials to crush, the size, hardness, humidity and other properties of the raw material particle size, how large the output is, the particle shape requirements, how many specifications are required, the hourly production requirements, how large the installation site is, etc.

Secondly, after clarifying the production needs, you can choose which process equipment to configure according to the budget. Taking the main crushing equipment as an example, there are many solutions to achieve stone crushing, some of which are of good quality, some are of high efficiency, and some are of low investment. Some can crush high-hardness materials, low-hardness materials, and materials with high moisture content. Some can only handle brittle materials, etc. If users want to save more money on investment, they need to reasonably configure according to the properties of their crushed materials and production requirements.

Then, auxiliary equipment such as feeding, screening, and conveying equipment can also save users a lot of investment and create high returns. The type and model of feeding equipment needs to be determined according to the stone mining capacity of the gravel plant and the production capacity of the primary crusher equipment; the type and quantity of screening equipment needs to be determined according to the production capacity of the fine crusher and the requirements of stone specifications; the type and length of conveying equipment needs to be determined according to the needs of the main equipment.

Previous: SMP Crusher

Next: SMP Crusher

What are the factors that affect the production capacity of stone impact crusher?

What are the factors that affect the production capacity of stone impact crusher? What are the new granite sand making equipment production equipment? What are the advantages

What are the new granite sand making equipment production equipment? What are the advantages Features and technical advantages of Shibang multi-cylinder hydraulic cone crusher

Features and technical advantages of Shibang multi-cylinder hydraulic cone crusher How much is a set of new sand making machine production equipment

How much is a set of new sand making machine production equipment What are the differences between impact crusher and cone crusher in sand making?

What are the differences between impact crusher and cone crusher in sand making? What are the factors that affect the production capacity of stone impact crusher?

What are the factors that affect the production capacity of stone impact crusher? What are the new granite sand making equipment production equipment? What are the advantages

What are the new granite sand making equipment production equipment? What are the advantages Features and technical advantages of Shibang multi-cylinder hydraulic cone crusher

Features and technical advantages of Shibang multi-cylinder hydraulic cone crusher How much is a set of new sand making machine production equipment

How much is a set of new sand making machine production equipment What are the differences between impact crusher and cone crusher in sand making?

What are the differences between impact crusher and cone crusher in sand making?