To improve the efficiency of the sand making machine during the production of machine-made sand, pay attention to the following points:Learn more about ways to improve the efficiency of the sand making machine1. Choose the rig

To improve the efficiency of the sand making machine during the production of machine-made sand, pay attention to the following points:

Learn more about ways to improve the efficiency of the sand making machine

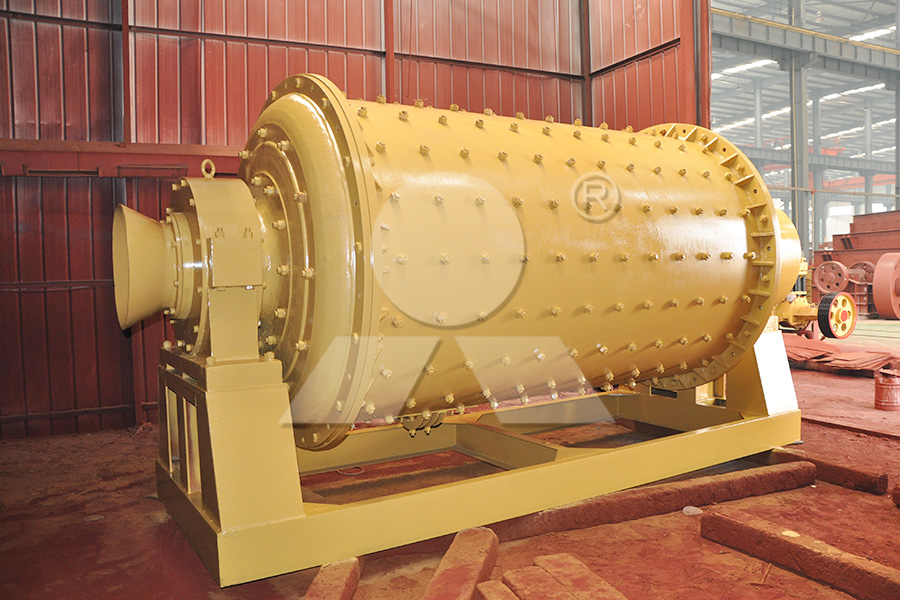

1. Choose the right sand making machine

Choosing the right sand making machine is the key to increasing production. When selecting, it is necessary to customize the selection based on the hardness, viscosity, humidity and other characteristics of the raw materials so that the equipment can efficiently process the raw materials, improve production efficiency and maximize production. For example, when processing raw materials with high hardness, a wear-resistant sand making machine should be selected; when facing raw materials with high humidity, the moisture content should be tested and adjusted to the appropriate range before processing, which can reduce equipment wear and increase production.

2. Optimize operating specifications

1. Pre-start inspection: Before starting the sand making machine, be sure to do a good job of inspection. First check whether the vortex chamber observation door is closed to prevent the material from gushing out and causing danger. Then confirm that the impeller is rotating in the correct direction, and then let the sand making machine run under no-load conditions. After careful inspection and confirmation that there are no abnormal conditions, the material feeding operation can be carried out.

2. Control the feed particle size: The feed particle size of the material must strictly follow the regulations and must not exceed the required range of the sand making machine. Too large a feed particle size will cause excessive wear of the impeller and unbalanced operation, thereby reducing production. Therefore, be sure to do a good job of screening before feeding, accurately control the particle size, ensure that the feed particle size is in an appropriate range, and ensure the efficient operation of the sand making machine.

3. Continuous operation: The sand making machine should operate continuously, even when feeding. Avoid frequent start and stop of the equipment to reduce the impact and wear on the equipment.

4. Pay attention to the operating conditions: During the operation of the sand making machine, pay attention to whether there are violent vibrations and abnormal sounds. Once an abnormal situation is found, the machine should be stopped immediately for inspection and troubleshooting.

3. Strengthen maintenance and maintenance

Regular maintenance of the sand making machine can effectively increase production and extend the service life of the equipment. Maintenance work includes lubrication, cleaning, and inspection of equipment components. Specifically, maintenance should be carried out from the following aspects:

1. Regularly check the wear: Open the observation door regularly to check the internal wear of the sand making machine, including the intermediate feed pipe, the upper and lower impeller liners of the impeller, the peripheral guard plate, the cone cap, the wear-resistant block, etc. If there is wear, it should be repaired or replaced in time. When replacing the wear-resistant block, make sure that the weight of each wear-resistant block is the same.

2. Regular lubrication: The sand making machine should be lubricated regularly to ensure the normal operation of all parts of the machine.

3. Adjust the transmission V-belt: The tension of the transmission V-belt of the sand making machine should be adjusted appropriately to ensure that the V-belt is evenly stressed.

4. Pay attention to equipment cleaning: Clean the sand making machine regularly to keep the inside and outside of the equipment clean. Especially for materials with higher viscosity, the inner wall of the sand making machine needs to be cleaned regularly to ensure the normal operation of the equipment.

Previous: SMP Crusher

Next: SMP Crusher

To improve the efficiency of the sand making machine during the production of machine-made sand, pay attention to the following points:Learn more about ways to improve the efficiency of the sand making machine1. Choose the rig

To improve the efficiency of the sand making machine during the production of machine-made sand, pay attention to the following points:

Learn more about ways to improve the efficiency of the sand making machine

1. Choose the right sand making machine

Choosing the right sand making machine is the key to increasing production. When selecting, it is necessary to customize the selection based on the hardness, viscosity, humidity and other characteristics of the raw materials so that the equipment can efficiently process the raw materials, improve production efficiency and maximize production. For example, when processing raw materials with high hardness, a wear-resistant sand making machine should be selected; when facing raw materials with high humidity, the moisture content should be tested and adjusted to the appropriate range before processing, which can reduce equipment wear and increase production.

2. Optimize operating specifications

1. Pre-start inspection: Before starting the sand making machine, be sure to do a good job of inspection. First check whether the vortex chamber observation door is closed to prevent the material from gushing out and causing danger. Then confirm that the impeller is rotating in the correct direction, and then let the sand making machine run under no-load conditions. After careful inspection and confirmation that there are no abnormal conditions, the material feeding operation can be carried out.

2. Control the feed particle size: The feed particle size of the material must strictly follow the regulations and must not exceed the required range of the sand making machine. Too large a feed particle size will cause excessive wear of the impeller and unbalanced operation, thereby reducing production. Therefore, be sure to do a good job of screening before feeding, accurately control the particle size, ensure that the feed particle size is in an appropriate range, and ensure the efficient operation of the sand making machine.

3. Continuous operation: The sand making machine should operate continuously, even when feeding. Avoid frequent start and stop of the equipment to reduce the impact and wear on the equipment.

4. Pay attention to the operating conditions: During the operation of the sand making machine, pay attention to whether there are violent vibrations and abnormal sounds. Once an abnormal situation is found, the machine should be stopped immediately for inspection and troubleshooting.

3. Strengthen maintenance and maintenance

Regular maintenance of the sand making machine can effectively increase production and extend the service life of the equipment. Maintenance work includes lubrication, cleaning, and inspection of equipment components. Specifically, maintenance should be carried out from the following aspects:

1. Regularly check the wear: Open the observation door regularly to check the internal wear of the sand making machine, including the intermediate feed pipe, the upper and lower impeller liners of the impeller, the peripheral guard plate, the cone cap, the wear-resistant block, etc. If there is wear, it should be repaired or replaced in time. When replacing the wear-resistant block, make sure that the weight of each wear-resistant block is the same.

2. Regular lubrication: The sand making machine should be lubricated regularly to ensure the normal operation of all parts of the machine.

3. Adjust the transmission V-belt: The tension of the transmission V-belt of the sand making machine should be adjusted appropriately to ensure that the V-belt is evenly stressed.

4. Pay attention to equipment cleaning: Clean the sand making machine regularly to keep the inside and outside of the equipment clean. Especially for materials with higher viscosity, the inner wall of the sand making machine needs to be cleaned regularly to ensure the normal operation of the equipment.

Previous: SMP Crusher

Next: SMP Crusher

How to configure a production line with an annual output of one million tons of machine-made sand

How to configure a production line with an annual output of one million tons of machine-made sand What are the large-scale stone crushing machines? Can they produce high-quality stones?

What are the large-scale stone crushing machines? Can they produce high-quality stones? Application of fine crushing equipment in large stone production lines

Application of fine crushing equipment in large stone production lines Liming Cone Crusher Enables Millions of Tons of Sand and Gravel Aggregate Project- Boosting Green Mining and Regional Development

Liming Cone Crusher Enables Millions of Tons of Sand and Gravel Aggregate Project- Boosting Green Mining and Regional Development How much does a 500 tons per hour sand making machine cost?

How much does a 500 tons per hour sand making machine cost? How to configure a production line with an annual output of one million tons of machine-made sand

How to configure a production line with an annual output of one million tons of machine-made sand What are the large-scale stone crushing machines? Can they produce high-quality stones?

What are the large-scale stone crushing machines? Can they produce high-quality stones? Application of fine crushing equipment in large stone production lines

Application of fine crushing equipment in large stone production lines Liming Cone Crusher Enables Millions of Tons of Sand and Gravel Aggregate Project- Boosting Green Mining and Regional Development

Liming Cone Crusher Enables Millions of Tons of Sand and Gravel Aggregate Project- Boosting Green Mining and Regional Development How much does a 500 tons per hour sand making machine cost?

How much does a 500 tons per hour sand making machine cost?