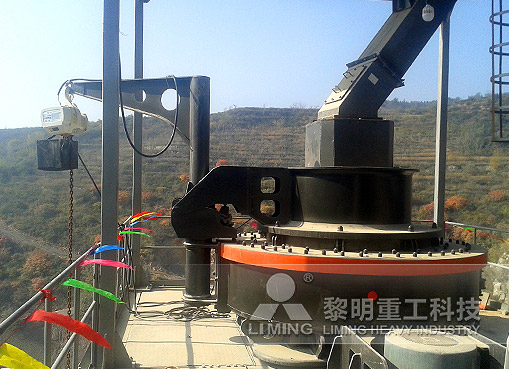

The methods to increase the production capacity of cone crushers are as follows:Click here to consult the price of cone crushers1. Choose a suitable cone crusher: When choosing a cone crusher, we should take equipment quality,

The methods to increase the production capacity of cone crushers are as follows:

Click here to consult the price of cone crushers

1. Choose a suitable cone crusher: When choosing a cone crusher, we should take equipment quality, operation stability, and efficient production capacity as key indicators based on production scale and material characteristics. Prioritize the selection of equipment that can adapt to working conditions, operate stably and produce high yields to ensure smooth operation of the production line, significantly improve overall efficiency, and ultimately maximize benefits.

2. Optimize the supply and storage of materials: The material supply and storage links play a decisive role in production efficiency. Adequate and stable material supply is the foundation. We must do our best to prevent material shortages or supply fluctuations to ensure that production can proceed in an orderly manner, prevent material problems from slowing down progress and reducing production, and lay a solid foundation for efficient production in all aspects.

3. Strictly control the feed particle size of materials: Strict control of feed particle size is the key to the efficient operation of cone crushers. During operation, we must strictly follow the equipment specifications, accurately control the material particle size, prevent excessively large particles from damaging the equipment, and prevent excessively small particles from affecting the crushing effect, so as to ensure crushing efficiency, maintain stable production, and further improve overall production capacity.

4. Do a good job of crusher maintenance: The maintenance of the crusher is related to its normal operation and service life. Operators must operate in accordance with the equipment manual and pay attention to equipment maintenance on a daily basis. For wearing parts, they need to be replaced in time according to the wear condition, so as to ensure the stable operation of the crusher, maintain good production efficiency, and give full play to the value of the equipment.

5. Strengthen the management and monitoring of the crusher: It is necessary to strengthen the management and monitoring of the cone crusher, establish a complete maintenance record and equipment file, timely discover and handle equipment failures, and ensure the normal operation and production efficiency of the equipment.

Previous: SMP Crusher

Next: SMP Crusher

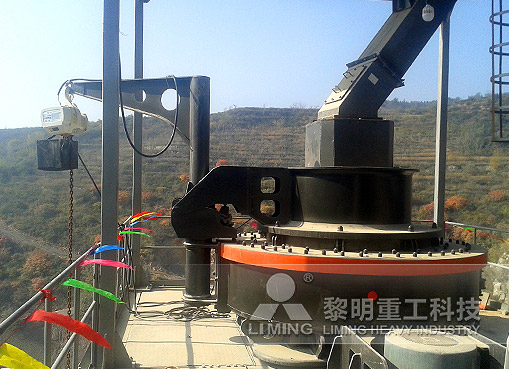

The methods to increase the production capacity of cone crushers are as follows:Click here to consult the price of cone crushers1. Choose a suitable cone crusher: When choosing a cone crusher, we should take equipment quality,

The methods to increase the production capacity of cone crushers are as follows:

Click here to consult the price of cone crushers

1. Choose a suitable cone crusher: When choosing a cone crusher, we should take equipment quality, operation stability, and efficient production capacity as key indicators based on production scale and material characteristics. Prioritize the selection of equipment that can adapt to working conditions, operate stably and produce high yields to ensure smooth operation of the production line, significantly improve overall efficiency, and ultimately maximize benefits.

2. Optimize the supply and storage of materials: The material supply and storage links play a decisive role in production efficiency. Adequate and stable material supply is the foundation. We must do our best to prevent material shortages or supply fluctuations to ensure that production can proceed in an orderly manner, prevent material problems from slowing down progress and reducing production, and lay a solid foundation for efficient production in all aspects.

3. Strictly control the feed particle size of materials: Strict control of feed particle size is the key to the efficient operation of cone crushers. During operation, we must strictly follow the equipment specifications, accurately control the material particle size, prevent excessively large particles from damaging the equipment, and prevent excessively small particles from affecting the crushing effect, so as to ensure crushing efficiency, maintain stable production, and further improve overall production capacity.

4. Do a good job of crusher maintenance: The maintenance of the crusher is related to its normal operation and service life. Operators must operate in accordance with the equipment manual and pay attention to equipment maintenance on a daily basis. For wearing parts, they need to be replaced in time according to the wear condition, so as to ensure the stable operation of the crusher, maintain good production efficiency, and give full play to the value of the equipment.

5. Strengthen the management and monitoring of the crusher: It is necessary to strengthen the management and monitoring of the cone crusher, establish a complete maintenance record and equipment file, timely discover and handle equipment failures, and ensure the normal operation and production efficiency of the equipment.

Previous: SMP Crusher

Next: SMP Crusher

Artificial VS Natural, Why Artificial Sand Is Not Inferior to Natural Sand

Artificial VS Natural, Why Artificial Sand Is Not Inferior to Natural Sand How to improve the working efficiency of jaw crusher

How to improve the working efficiency of jaw crusher What are the effects of the properties of the raw materials on the screening efficiency of the vibrating screen?

What are the effects of the properties of the raw materials on the screening efficiency of the vibrating screen? What are the hazards of noise during the operation of mining equipment?

What are the hazards of noise during the operation of mining equipment? What to look for when buying an iron ore crusher

What to look for when buying an iron ore crusher Artificial VS Natural, Why Artificial Sand Is Not Inferior to Natural Sand

Artificial VS Natural, Why Artificial Sand Is Not Inferior to Natural Sand How to improve the working efficiency of jaw crusher

How to improve the working efficiency of jaw crusher What are the effects of the properties of the raw materials on the screening efficiency of the vibrating screen?

What are the effects of the properties of the raw materials on the screening efficiency of the vibrating screen? What are the hazards of noise during the operation of mining equipment?

What are the hazards of noise during the operation of mining equipment? What to look for when buying an iron ore crusher

What to look for when buying an iron ore crusher