The quality of concrete is greatly affected by sand and gravel aggregates. High-quality aggregates require high strength and low porosity. The "jaw + cone" crusher combination is recommended to efficiently process high-hardness materials. The

The quality of concrete is greatly affected by sand and gravel aggregates. High-quality aggregates require high strength and low porosity. The "jaw + cone" crusher combination is recommended to efficiently process high-hardness materials. The efficient production line configuration includes vibrating feeding, crushing, sand making, and screening equipment, and the machine-made sand equipment improves the performance of concrete.

Concrete is an indispensable and important raw material in modern infrastructure construction, and its quality directly affects the service life of the building. As the main component that occupies 70% of the volume and 80% of the mass of concrete, the quality of sand and gravel aggregates has a very important impact on the finished concrete products. Selecting high-quality raw materials and rationally configuring sand and gravel production lines are the key to commercial concrete companies to effectively save costs and improve economic benefits.

Recommended aggregate crushing and processing equipment for concrete

Selection of concrete aggregates

Sand, gravel or pebbles play a skeleton and filling role in concrete, inhibiting the shrinkage of cement and enhancing the structural stability of concrete. The types of rocks used for concrete aggregates mainly include river pebbles, granite, marble, dolomite, etc. These rocks can be processed into gravel or sand that meets the needs of concrete.

How to choose the right rock? High-quality concrete aggregates should have high compressive strength, good deformation resistance, low density and low porosity. Rocks such as river pebbles and granite are often used in the production of high-quality concrete due to their excellent physical properties.

Equipment recommendation for producing concrete aggregates

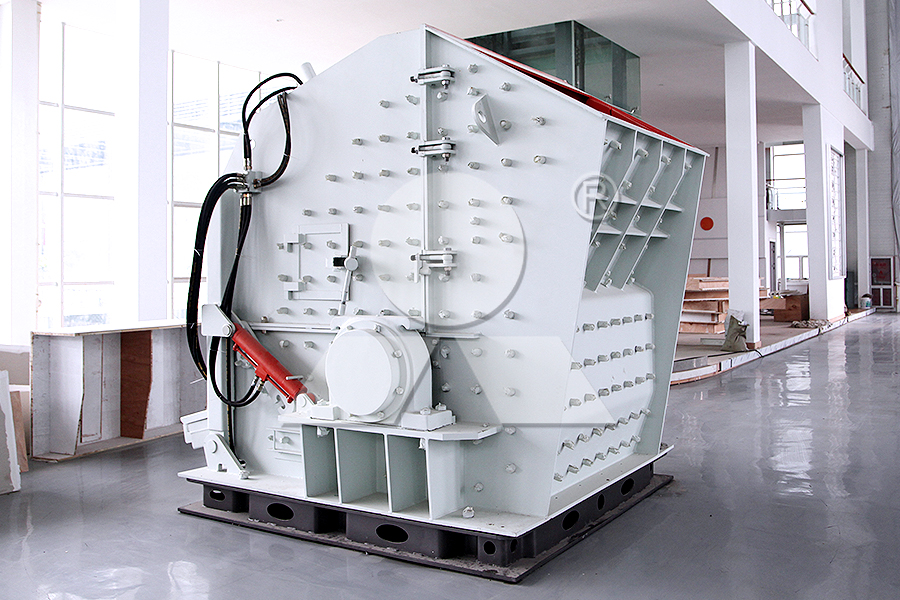

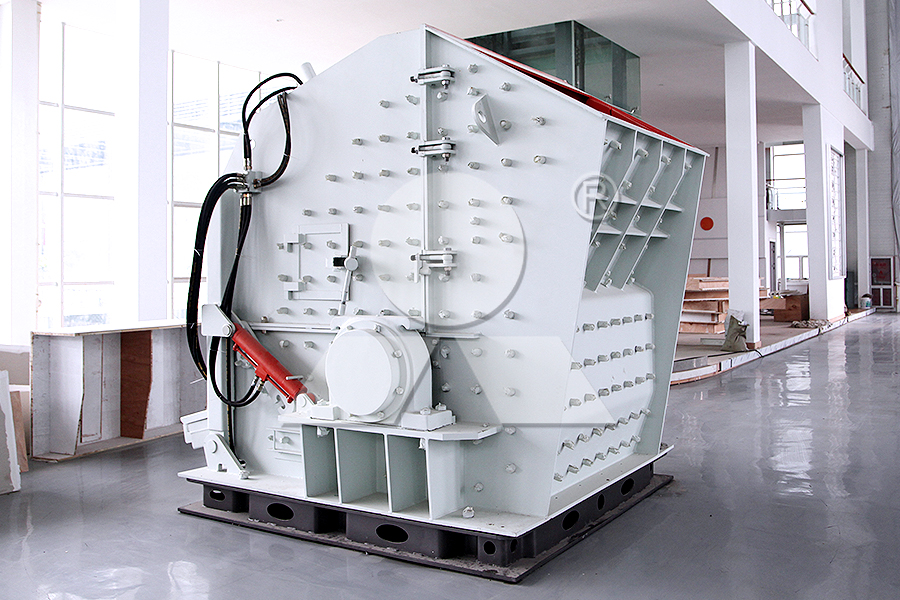

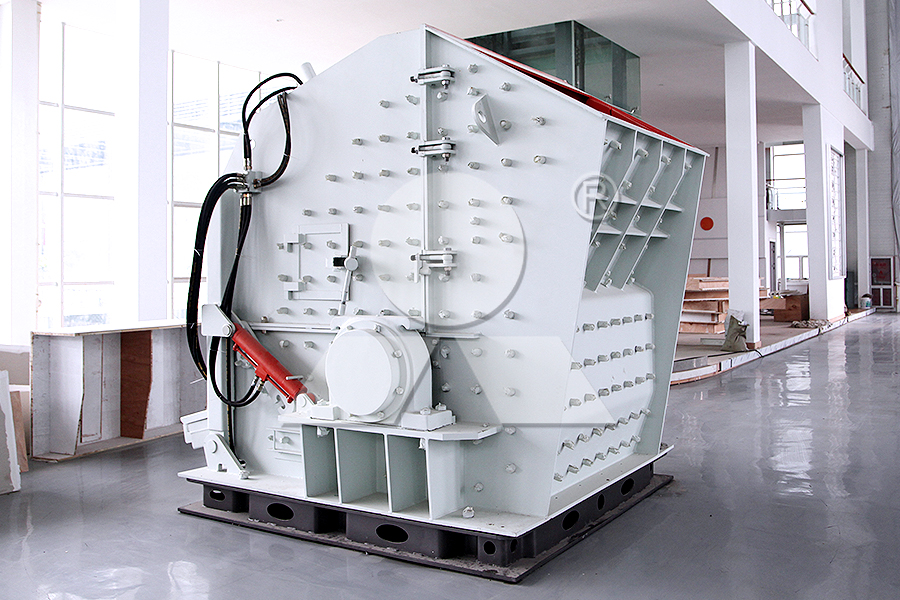

Since rocks suitable for concrete aggregates are generally hard, it is particularly important to choose suitable crushing equipment. In the current market, the combination of "jaw crusher + cone crusher" is an ideal choice for processing high-hardness materials.

Jaw crusher:

Processing capacity: 15-1510 t/h

Advantages: Jaw crusher is suitable for primary crushing of bulk materials. The optimized motion parameters and deep crushing chamber design ensure efficient production without blockage. It has a compact structure, easy installation and simple operation.

Cone crusher:

Processing capacity: 45-2130 t/h

Advantages: Cone crusher is suitable for medium and fine crushing, especially for processing high-hardness materials. Its intelligent automatic control system is convenient for remote operation, has strong wear resistance, can reduce later operating costs and extend equipment life.

Typical concrete aggregate production line configuration

An efficient concrete aggregate production line usually includes the following equipment combination: vibrating feeder, jaw crusher, single cylinder hydraulic cone crusher, sand making machine (shaping), vibrating screen, silo feeder. The following is a typical configuration of a concrete gravel production line:

Feed size: ≤650 mm

Processing capacity: 350 tons per hour

Finished product specifications: 5-10mm, 10-20mm, 20-31.5mm

Solution advantages: This combination configuration not only ensures production efficiency, but also improves the quality of finished products. The entire production line is easy to operate, with low energy consumption, uniform finished product particle size, less needle-like, and significant economic benefits.

Application of sand making equipment

With the development of the construction industry and the increasing attention to engineering quality, machine-made sand has gradually replaced natural sand as an important source of construction sand. Vertical impact crusher is an important equipment for producing high-quality machine-made sand. The sand and gravel produced have excellent particle shape and uniform particle size, and the performance of the concrete produced is comparable to that of natural sand concrete.

The overall quality of concrete depends not only on the selection of aggregates, but also on the production equipment. Rationally selecting crushers and sand making machines and configuring production lines according to project requirements are effective ways to ensure concrete quality and corporate benefits.

Previous: SMP Crusher

Next: SMP Crusher

The quality of concrete is greatly affected by sand and gravel aggregates. High-quality aggregates require high strength and low porosity. The "jaw + cone" crusher combination is recommended to efficiently process high-hardness materials. The

The quality of concrete is greatly affected by sand and gravel aggregates. High-quality aggregates require high strength and low porosity. The "jaw + cone" crusher combination is recommended to efficiently process high-hardness materials. The efficient production line configuration includes vibrating feeding, crushing, sand making, and screening equipment, and the machine-made sand equipment improves the performance of concrete.

Concrete is an indispensable and important raw material in modern infrastructure construction, and its quality directly affects the service life of the building. As the main component that occupies 70% of the volume and 80% of the mass of concrete, the quality of sand and gravel aggregates has a very important impact on the finished concrete products. Selecting high-quality raw materials and rationally configuring sand and gravel production lines are the key to commercial concrete companies to effectively save costs and improve economic benefits.

Recommended aggregate crushing and processing equipment for concrete

Selection of concrete aggregates

Sand, gravel or pebbles play a skeleton and filling role in concrete, inhibiting the shrinkage of cement and enhancing the structural stability of concrete. The types of rocks used for concrete aggregates mainly include river pebbles, granite, marble, dolomite, etc. These rocks can be processed into gravel or sand that meets the needs of concrete.

How to choose the right rock? High-quality concrete aggregates should have high compressive strength, good deformation resistance, low density and low porosity. Rocks such as river pebbles and granite are often used in the production of high-quality concrete due to their excellent physical properties.

Equipment recommendation for producing concrete aggregates

Since rocks suitable for concrete aggregates are generally hard, it is particularly important to choose suitable crushing equipment. In the current market, the combination of "jaw crusher + cone crusher" is an ideal choice for processing high-hardness materials.

Jaw crusher:

Processing capacity: 15-1510 t/h

Advantages: Jaw crusher is suitable for primary crushing of bulk materials. The optimized motion parameters and deep crushing chamber design ensure efficient production without blockage. It has a compact structure, easy installation and simple operation.

Cone crusher:

Processing capacity: 45-2130 t/h

Advantages: Cone crusher is suitable for medium and fine crushing, especially for processing high-hardness materials. Its intelligent automatic control system is convenient for remote operation, has strong wear resistance, can reduce later operating costs and extend equipment life.

Typical concrete aggregate production line configuration

An efficient concrete aggregate production line usually includes the following equipment combination: vibrating feeder, jaw crusher, single cylinder hydraulic cone crusher, sand making machine (shaping), vibrating screen, silo feeder. The following is a typical configuration of a concrete gravel production line:

Feed size: ≤650 mm

Processing capacity: 350 tons per hour

Finished product specifications: 5-10mm, 10-20mm, 20-31.5mm

Solution advantages: This combination configuration not only ensures production efficiency, but also improves the quality of finished products. The entire production line is easy to operate, with low energy consumption, uniform finished product particle size, less needle-like, and significant economic benefits.

Application of sand making equipment

With the development of the construction industry and the increasing attention to engineering quality, machine-made sand has gradually replaced natural sand as an important source of construction sand. Vertical impact crusher is an important equipment for producing high-quality machine-made sand. The sand and gravel produced have excellent particle shape and uniform particle size, and the performance of the concrete produced is comparable to that of natural sand concrete.

The overall quality of concrete depends not only on the selection of aggregates, but also on the production equipment. Rationally selecting crushers and sand making machines and configuring production lines according to project requirements are effective ways to ensure concrete quality and corporate benefits.

Previous: SMP Crusher

Next: SMP Crusher

Can cone crusher process iron ore? How much does one cost?

Can cone crusher process iron ore? How much does one cost? What factors should be paid attention to when choosing large stone crusher equipment

What factors should be paid attention to when choosing large stone crusher equipment bauma China 2024 Shanghai

bauma China 2024 Shanghai Introduction to the advantages and disadvantages of dry sand making and wet sand making in artificial sand making

Introduction to the advantages and disadvantages of dry sand making and wet sand making in artificial sand making Equipment required for coal crushing with an output of 700 tons per hour

Equipment required for coal crushing with an output of 700 tons per hour Can cone crusher process iron ore? How much does one cost?

Can cone crusher process iron ore? How much does one cost? What factors should be paid attention to when choosing large stone crusher equipment

What factors should be paid attention to when choosing large stone crusher equipment bauma China 2024 Shanghai

bauma China 2024 Shanghai Introduction to the advantages and disadvantages of dry sand making and wet sand making in artificial sand making

Introduction to the advantages and disadvantages of dry sand making and wet sand making in artificial sand making Equipment required for coal crushing with an output of 700 tons per hour

Equipment required for coal crushing with an output of 700 tons per hour