The keys to increasing the production capacity of a pebble sand production line include standardized operations to minimize downtime, pre-treatment of raw materials to ensure stability, and regular maintenance to extend machine life. Uniform feeding an

The keys to increasing the production capacity of a pebble sand production line include standardized operations to minimize downtime, pre-treatment of raw materials to ensure stability, and regular maintenance to extend machine life. Uniform feeding and wear inspection are the key to efficient sand production.

The sand making machine is the primary equipment in a sand making line. To improve the production capacity of a pebble sand making line, consider the following points:

1. Standardize operating procedures

Rational and standardized operations are crucial. They significantly reduce the frequency of downtime and maintenance for the pebble sand making machine, effectively extending its operating time and ensuring continuous and stable operation. This, in turn, improves the overall performance of the pebble sand making machine and ensures efficient and orderly production.

2. Control the feed material

Pebble sand with high hardness, moisture, or viscosity requires pre-crushing and drying. Sand and gravel with high fines content and the tendency for fines to adhere and affect conveying should be screened to minimize fines and prevent them from interfering with the pebble sand making machine's operation, ensuring stable and efficient sand production.

When feeding the sand making machine with a belt conveyor or vibrating feeder, ensure that the material is fed evenly. Overfeeding or underfeeding will affect the performance of the river pebble sand making machine.

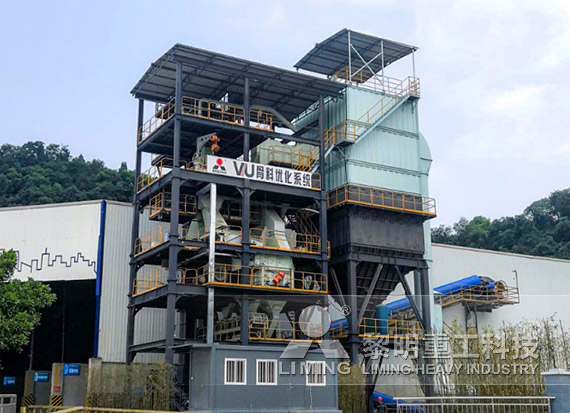

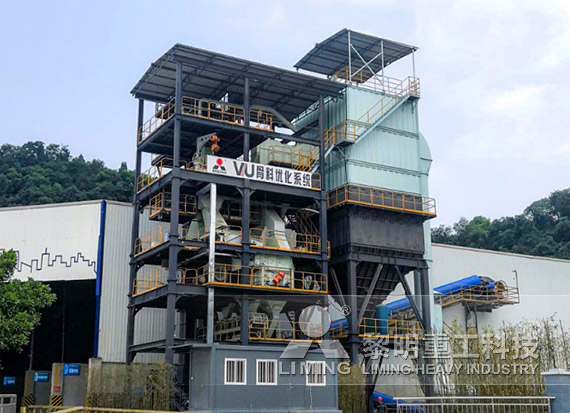

VSI6X Sand Making Machine

3. Regular Maintenance

To ensure stable operation of the river pebble sand making machine, it is necessary to regularly shut down the machine, open the inspection door, and carefully inspect the wear of various internal components, such as the center feed pipe, cone cap, impeller upper and lower flow channel liners, circumferential guard plates, and wear blocks. If any components are worn, replace or repair them promptly. When replacing wear blocks, ensure that the new blocks are of the same weight to maintain machine balance.

Previous: SMP Crusher

Next: SMP Crusher

The keys to increasing the production capacity of a pebble sand production line include standardized operations to minimize downtime, pre-treatment of raw materials to ensure stability, and regular maintenance to extend machine life. Uniform feeding an

The keys to increasing the production capacity of a pebble sand production line include standardized operations to minimize downtime, pre-treatment of raw materials to ensure stability, and regular maintenance to extend machine life. Uniform feeding and wear inspection are the key to efficient sand production.

The sand making machine is the primary equipment in a sand making line. To improve the production capacity of a pebble sand making line, consider the following points:

1. Standardize operating procedures

Rational and standardized operations are crucial. They significantly reduce the frequency of downtime and maintenance for the pebble sand making machine, effectively extending its operating time and ensuring continuous and stable operation. This, in turn, improves the overall performance of the pebble sand making machine and ensures efficient and orderly production.

2. Control the feed material

Pebble sand with high hardness, moisture, or viscosity requires pre-crushing and drying. Sand and gravel with high fines content and the tendency for fines to adhere and affect conveying should be screened to minimize fines and prevent them from interfering with the pebble sand making machine's operation, ensuring stable and efficient sand production.

When feeding the sand making machine with a belt conveyor or vibrating feeder, ensure that the material is fed evenly. Overfeeding or underfeeding will affect the performance of the river pebble sand making machine.

VSI6X Sand Making Machine

3. Regular Maintenance

To ensure stable operation of the river pebble sand making machine, it is necessary to regularly shut down the machine, open the inspection door, and carefully inspect the wear of various internal components, such as the center feed pipe, cone cap, impeller upper and lower flow channel liners, circumferential guard plates, and wear blocks. If any components are worn, replace or repair them promptly. When replacing wear blocks, ensure that the new blocks are of the same weight to maintain machine balance.

Previous: SMP Crusher

Next: SMP Crusher

What influence do ore material properties have on stone crushing equipment

What influence do ore material properties have on stone crushing equipment What influence do ore material properties have on stone crushing equipment

What influence do ore material properties have on stone crushing equipment How to adjust the particle size of impact crusher

How to adjust the particle size of impact crusher Full-scale production of Shibang and Anhui Communications Control Group to build an annual output of 60 million tons of aggregate project

Full-scale production of Shibang and Anhui Communications Control Group to build an annual output of 60 million tons of aggregate project What are the advantages of Shibang aggregate sand making equipment production line equipment

What are the advantages of Shibang aggregate sand making equipment production line equipment What influence do ore material properties have on stone crushing equipment

What influence do ore material properties have on stone crushing equipment What influence do ore material properties have on stone crushing equipment

What influence do ore material properties have on stone crushing equipment How to adjust the particle size of impact crusher

How to adjust the particle size of impact crusher Full-scale production of Shibang and Anhui Communications Control Group to build an annual output of 60 million tons of aggregate project

Full-scale production of Shibang and Anhui Communications Control Group to build an annual output of 60 million tons of aggregate project What are the advantages of Shibang aggregate sand making equipment production line equipment

What are the advantages of Shibang aggregate sand making equipment production line equipment