The daily maintenance of the mobile sand making and crushing machine is as follows:Click here to consult for maintenance knowledge of the mobile sand making and crushing machineFor the mobile sand making and crushing machine,

The daily maintenance of the mobile sand making and crushing machine is as follows:

Click here to consult for maintenance knowledge of the mobile sand making and crushing machine

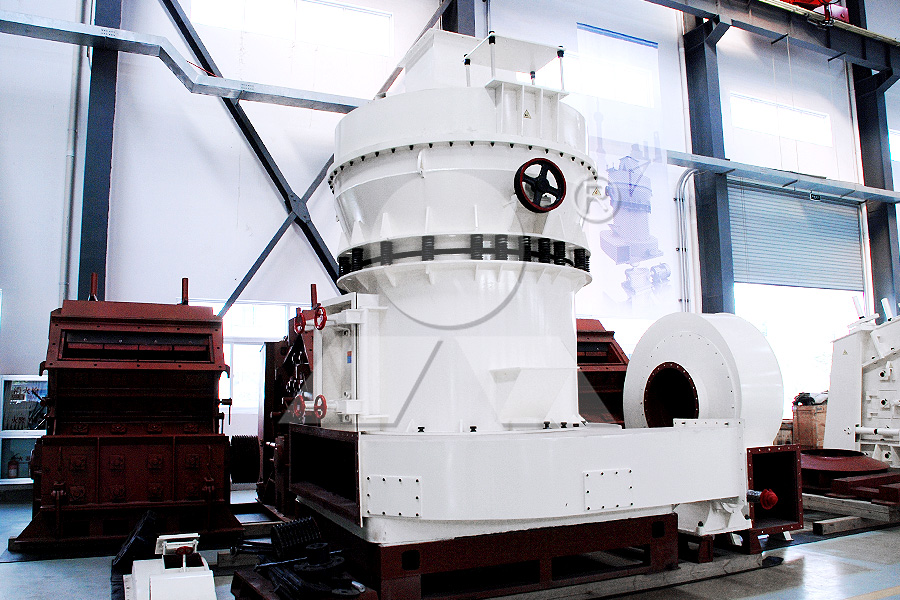

For the mobile sand making and crushing machine, the daily maintenance work is mainly in three aspects: component wear inspection, lubrication and equipment cleaning.

1. It is necessary to regularly check the wear of the components of the mobile crushing station, especially the key parts such as the center feed pipe, cone cap, upper and lower flow channel linings of the impeller, circumferential guard plates and jaw plates. Once these parts are found to be severely worn, measures must be taken immediately to repair or replace them to ensure the normal operation of the equipment. When replacing parts, be sure to pay attention to the weight, model and size of the new parts to ensure that they are exactly the same as the original parts to avoid equipment failure or safety hazards due to mismatch. Through meticulous maintenance and timely replacement, the service life of the mobile crushing station can be extended and production efficiency can be improved.

2. The lubrication of the mobile sand making and crushing machine is very important, and the friction surface needs to be lubricated in time. When selecting grease, the appropriate type should be determined according to the location and temperature conditions of use. Ensure correct lubrication to maintain the good operation of the equipment, reduce wear and extend the service life.

3. Keep the mobile sand making and crushing machine clean, and be careful not to let dust and other debris enter the lubrication system to avoid damaging the lubricating oil film. Try to avoid dust accumulation, oil pollution, oil leakage, water leakage, electricity leakage, and dust leakage. In addition, pay attention to the regular cleaning of the mobile crushing station bearings. After the crusher has worked for 2000 hours, open the main shaft assembly to clean the bearings. Generally, new bearings should be replaced after 7200 hours of work.

Previous: SMP Crusher

Next: SMP Crusher

The daily maintenance of the mobile sand making and crushing machine is as follows:Click here to consult for maintenance knowledge of the mobile sand making and crushing machineFor the mobile sand making and crushing machine,

The daily maintenance of the mobile sand making and crushing machine is as follows:

Click here to consult for maintenance knowledge of the mobile sand making and crushing machine

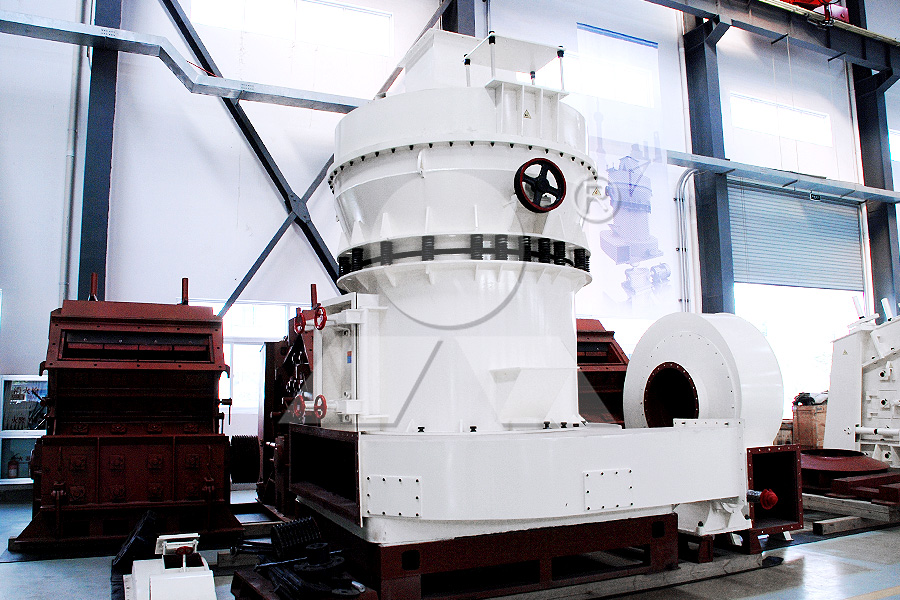

For the mobile sand making and crushing machine, the daily maintenance work is mainly in three aspects: component wear inspection, lubrication and equipment cleaning.

1. It is necessary to regularly check the wear of the components of the mobile crushing station, especially the key parts such as the center feed pipe, cone cap, upper and lower flow channel linings of the impeller, circumferential guard plates and jaw plates. Once these parts are found to be severely worn, measures must be taken immediately to repair or replace them to ensure the normal operation of the equipment. When replacing parts, be sure to pay attention to the weight, model and size of the new parts to ensure that they are exactly the same as the original parts to avoid equipment failure or safety hazards due to mismatch. Through meticulous maintenance and timely replacement, the service life of the mobile crushing station can be extended and production efficiency can be improved.

2. The lubrication of the mobile sand making and crushing machine is very important, and the friction surface needs to be lubricated in time. When selecting grease, the appropriate type should be determined according to the location and temperature conditions of use. Ensure correct lubrication to maintain the good operation of the equipment, reduce wear and extend the service life.

3. Keep the mobile sand making and crushing machine clean, and be careful not to let dust and other debris enter the lubrication system to avoid damaging the lubricating oil film. Try to avoid dust accumulation, oil pollution, oil leakage, water leakage, electricity leakage, and dust leakage. In addition, pay attention to the regular cleaning of the mobile crushing station bearings. After the crusher has worked for 2000 hours, open the main shaft assembly to clean the bearings. Generally, new bearings should be replaced after 7200 hours of work.

Previous: SMP Crusher

Next: SMP Crusher

How to improve the sand production efficiency of river pebble sand making machine

How to improve the sand production efficiency of river pebble sand making machine What are the steps to build a 10,000-ton sand and gravel production line per day?

What are the steps to build a 10,000-ton sand and gravel production line per day? The first choice of highway stone crusher - mobile stone crusher

The first choice of highway stone crusher - mobile stone crusher How to choose basalt crushing equipment

How to choose basalt crushing equipment What is the difference between single cylinder and multi-cylinder cone crusher?

What is the difference between single cylinder and multi-cylinder cone crusher? How to improve the sand production efficiency of river pebble sand making machine

How to improve the sand production efficiency of river pebble sand making machine What are the steps to build a 10,000-ton sand and gravel production line per day?

What are the steps to build a 10,000-ton sand and gravel production line per day? The first choice of highway stone crusher - mobile stone crusher

The first choice of highway stone crusher - mobile stone crusher How to choose basalt crushing equipment

How to choose basalt crushing equipment What is the difference between single cylinder and multi-cylinder cone crusher?

What is the difference between single cylinder and multi-cylinder cone crusher?