How to process high calcium stone and what equipment is used for processing powder? Generally speaking, high calcium stone is also called limestone, which is widely used and has more application areas. In order to make better and reaso

How to process high calcium stone and what equipment is used for processing powder? Generally speaking, high calcium stone is also called limestone, which is widely used and has more application areas. In order to make better and reasonable use of it, it needs to be ground into powder first.

High calcium stone powder is actually limestone powder, the main component is calcium carbonate, what types of high calcium stone powder production equipment? What is the working principle? How to find high calcium stone powder production equipment manufacturers? What is the role of high calcium stone powder?

Let's first understand the role of high calcium stone powder. High calcium stone powder is often used in flue gas desulfurization, asphalt mixing plant, concrete mixing plant, exterior wall putty, dry mortar, etc. It is the main desulfurizing agent for semi-dry flue gas desulfurization in thermal power plants, which can achieve the neutralization of acid and alkali in flue gas and reduce the emission of sulfur dioxide in the atmosphere. The other is the application in construction, asphalt mixing plant will need to mix a certain amount of stone powder for anti-cracking, concrete mixing plant will also use part of the stone powder instead of mineral powder to save costs. Exterior wall putty and dry mortar will also use high-calcium stone powder as part of the raw materials.

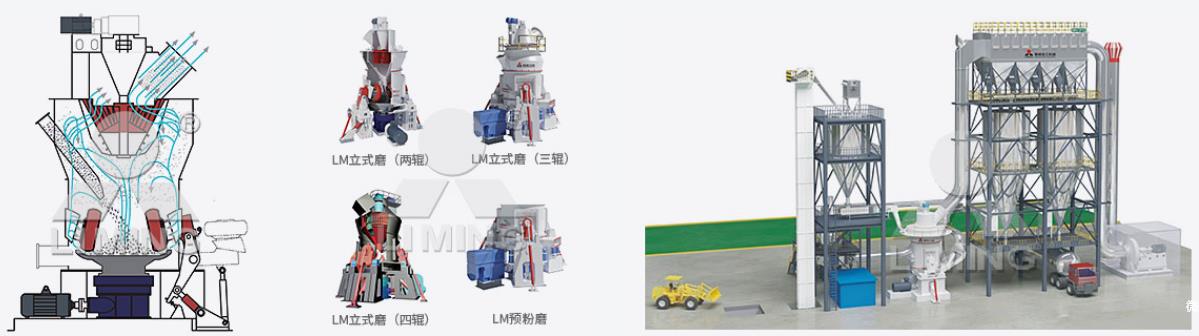

So, what are the high calcium stone powder production equipment. The common ones are Raymond mill and vertical mill. Among them, Raymond mill is a cost-effective grinding equipment, more common in the production of high calcium stone powder industry. LM vertical roller mill, MTW European version mill, 5X European version intelligent mill can be used for fine powder processing;

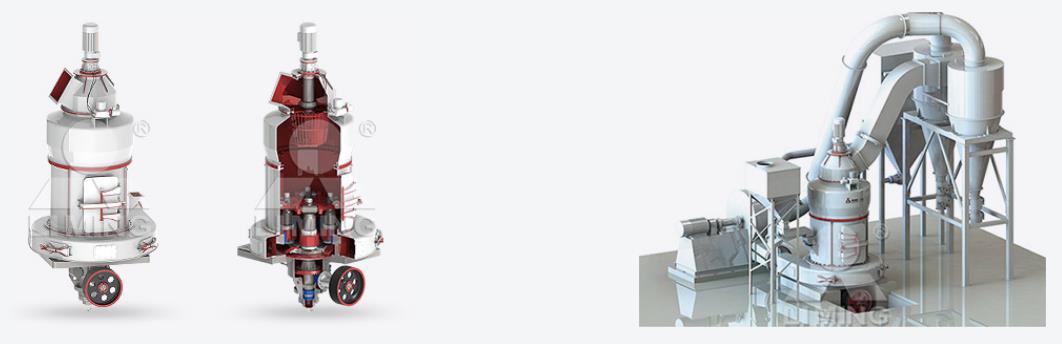

For ultra-fine powder processing, MW ring roller micro mill and LUM ultra-fine vertical mill can be used; for coarse powder processing, CM European type coarse powder mill can be used.

Guilin Hongcheng HC series pendulum mill is the new upgraded Raymond mill, which can process high calcium stone powder from 80 mesh to 400 mesh, and the output can reach more than 50 tons per hour.

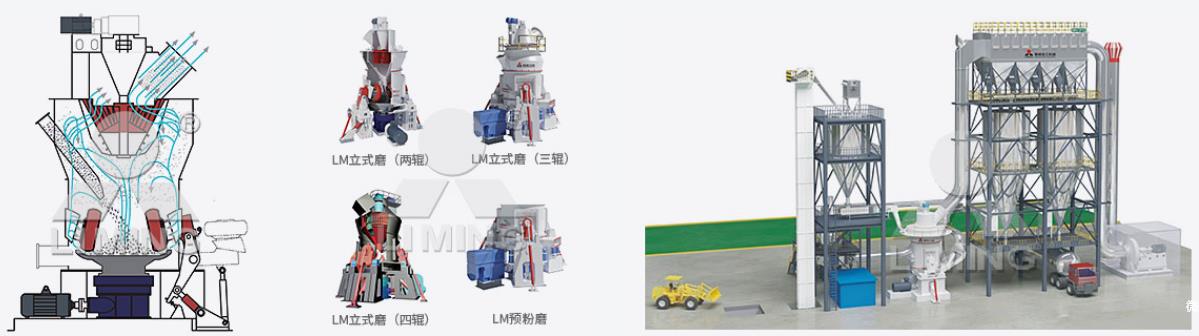

The working principle of LM series vertical mill of high calcium stone powder production equipment: LM series vertical mill is mainly composed of grinding roller assembly, grinding disk assembly, hydraulic station, transmission arm assembly, powder selector, main reducer, motor, body, main reducer lubrication station, hydraulic station, PLC electric control cabinet and other parts.

When working, the main motor drives the grinding disk through the reducer, while the hot air enters the vertical mill body from the air inlet, and the material falls in the middle of the grinding disk from the lower material inlet, under the action of centrifugal force, the material moves evenly from the middle to the edge of the grinding disk, and when passing through the grinding roller channel area on the grinding disk, it is crushed by the grinding roller, and the large pieces of material are directly crushed, and the fine-grained material is crushed by the extrusion to form the material bed for intergranular crushing. The crushed materials continue to move to the edge of the grinding plate until they are taken away by the strong airflow at the wind ring, while the larger granular materials fall back to the grinding plate to continue to be crushed, and the materials in the airflow pass through the upper separator, under the action of the rotor blades, the coarse particles return to the grinding plate for grinding, and the qualified fine powder comes out of the mill with the airflow and is collected by the system's powder collector, and the powder collected is the product of the vertical grinding. Iron and other debris mixed into the material with the movement of the material to the edge of the grinding plate, because of its own weight and can not be blown up by the wind, fell to the lower cavity of the mill was installed in the bottom of the grinding plate scraper scraping into the slag discharge mouth out of the machine.

High calcium stone powder production equipment of MTW European version mill working principle: MTW European version mill adopts a number of patented technologies such as bevel gear overall drive, internal thin oil lubrication system, curved air duct, etc., with high grinding efficiency, it is a replacement product for traditional Raymond mill and pendulum mill, and is widely used in power plant desulfurization, large non-metallic ore powder making and building materials and chemical industry. After crushing, the qualified materials are evenly and quantitatively fed into the grinding chamber of the main machine continuously through the frequency conversion belt feeder for grinding. Under the action of the analyzer, the materials that do not meet the fineness requirements fall into the grinding chamber for regrinding, while the qualified materials enter the cyclone powder collector through the duct with the airflow for separation and collection, and are discharged through the discharge device as finished powder. The separated airflow enters the fan through the return air duct at the upper end of the cyclone collector. The system operates under positive and negative pressure, and the equipment is equipped with pulse dust collector, which is environmentally friendly.

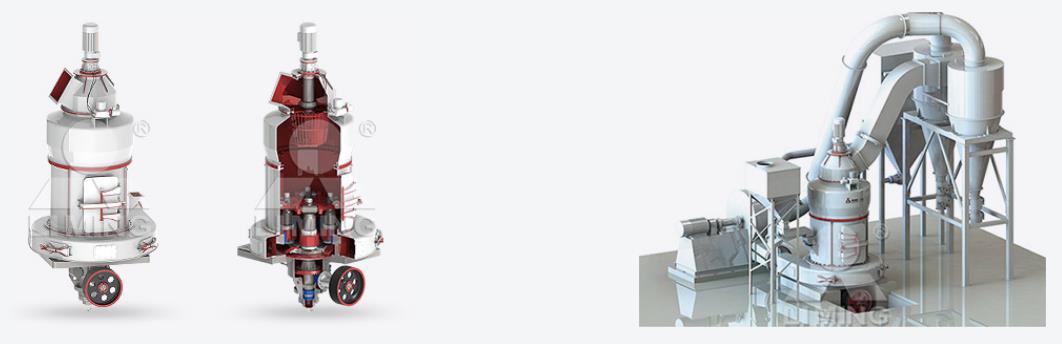

High calcium stone powder production equipment of the 5X series of the fifth generation of European version of intelligent grinding mill working principle: 5X series of the fifth generation of European version of intelligent grinding mill is a new intelligent grinding equipment based on thirty years of research and development experience to draw on new grinding technology, with a special structure design, full thin oil lubrication system, low resistance curved air duct and many other independent patented technology property rights. The intelligent grinding mill with large capacity and low energy consumption is also the preferred equipment for large-scale mineral processing plant construction and intelligent production of environmental protection.

The 5X series European version mill is a vertical structure, mainly composed of the main machine, fan, powder selector, special dust collector, cyclone collector, piping device, motor and other equipment, supporting auxiliary equipment can choose crusher, elevator, belt machine, electromagnetic vibrating feeder, silo, control cabinet and so on.

The material is sent evenly to the grinding chamber of the main machine through the feeding device. Under the action of centrifugal force and shovel, the material is crushed by squeezing and grinding between the grinding rollers and grinding rings, and the crushed material is blown to the powder separator for sorting under the action of wind.

The whole airflow system of the mill is a closed cycle, circulating under negative pressure. Firstly, the airflow generated by the fan along with the material enters the cyclone powder collector through the duct, the powder collector separates the material from the airflow, and the airflow returns to the fan through the return air duct, forming an air circulation system; secondly, the excess gas and micro powder are sent to the dust collector for filtration through the duct, the dust is collected by the dust collector, and the remaining air is purified and discharged, effectively protecting the environment.

As a professional grinding equipment manufacturer, SMPCRUSHER has strong strength, exquisite technology, advanced technology and reliable and stable product quality. For the latest quotation of high-calcium stone powder production equipment, welcome to leave a message immediately!

Previous: SMP Crusher

Next: SMP Crusher

How to process high calcium stone and what equipment is used for processing powder? Generally speaking, high calcium stone is also called limestone, which is widely used and has more application areas. In order to make better and reaso

How to process high calcium stone and what equipment is used for processing powder? Generally speaking, high calcium stone is also called limestone, which is widely used and has more application areas. In order to make better and reasonable use of it, it needs to be ground into powder first.

High calcium stone powder is actually limestone powder, the main component is calcium carbonate, what types of high calcium stone powder production equipment? What is the working principle? How to find high calcium stone powder production equipment manufacturers? What is the role of high calcium stone powder?

Let's first understand the role of high calcium stone powder. High calcium stone powder is often used in flue gas desulfurization, asphalt mixing plant, concrete mixing plant, exterior wall putty, dry mortar, etc. It is the main desulfurizing agent for semi-dry flue gas desulfurization in thermal power plants, which can achieve the neutralization of acid and alkali in flue gas and reduce the emission of sulfur dioxide in the atmosphere. The other is the application in construction, asphalt mixing plant will need to mix a certain amount of stone powder for anti-cracking, concrete mixing plant will also use part of the stone powder instead of mineral powder to save costs. Exterior wall putty and dry mortar will also use high-calcium stone powder as part of the raw materials.

So, what are the high calcium stone powder production equipment. The common ones are Raymond mill and vertical mill. Among them, Raymond mill is a cost-effective grinding equipment, more common in the production of high calcium stone powder industry. LM vertical roller mill, MTW European version mill, 5X European version intelligent mill can be used for fine powder processing;

For ultra-fine powder processing, MW ring roller micro mill and LUM ultra-fine vertical mill can be used; for coarse powder processing, CM European type coarse powder mill can be used.

Guilin Hongcheng HC series pendulum mill is the new upgraded Raymond mill, which can process high calcium stone powder from 80 mesh to 400 mesh, and the output can reach more than 50 tons per hour.

The working principle of LM series vertical mill of high calcium stone powder production equipment: LM series vertical mill is mainly composed of grinding roller assembly, grinding disk assembly, hydraulic station, transmission arm assembly, powder selector, main reducer, motor, body, main reducer lubrication station, hydraulic station, PLC electric control cabinet and other parts.

When working, the main motor drives the grinding disk through the reducer, while the hot air enters the vertical mill body from the air inlet, and the material falls in the middle of the grinding disk from the lower material inlet, under the action of centrifugal force, the material moves evenly from the middle to the edge of the grinding disk, and when passing through the grinding roller channel area on the grinding disk, it is crushed by the grinding roller, and the large pieces of material are directly crushed, and the fine-grained material is crushed by the extrusion to form the material bed for intergranular crushing. The crushed materials continue to move to the edge of the grinding plate until they are taken away by the strong airflow at the wind ring, while the larger granular materials fall back to the grinding plate to continue to be crushed, and the materials in the airflow pass through the upper separator, under the action of the rotor blades, the coarse particles return to the grinding plate for grinding, and the qualified fine powder comes out of the mill with the airflow and is collected by the system's powder collector, and the powder collected is the product of the vertical grinding. Iron and other debris mixed into the material with the movement of the material to the edge of the grinding plate, because of its own weight and can not be blown up by the wind, fell to the lower cavity of the mill was installed in the bottom of the grinding plate scraper scraping into the slag discharge mouth out of the machine.

High calcium stone powder production equipment of MTW European version mill working principle: MTW European version mill adopts a number of patented technologies such as bevel gear overall drive, internal thin oil lubrication system, curved air duct, etc., with high grinding efficiency, it is a replacement product for traditional Raymond mill and pendulum mill, and is widely used in power plant desulfurization, large non-metallic ore powder making and building materials and chemical industry. After crushing, the qualified materials are evenly and quantitatively fed into the grinding chamber of the main machine continuously through the frequency conversion belt feeder for grinding. Under the action of the analyzer, the materials that do not meet the fineness requirements fall into the grinding chamber for regrinding, while the qualified materials enter the cyclone powder collector through the duct with the airflow for separation and collection, and are discharged through the discharge device as finished powder. The separated airflow enters the fan through the return air duct at the upper end of the cyclone collector. The system operates under positive and negative pressure, and the equipment is equipped with pulse dust collector, which is environmentally friendly.

High calcium stone powder production equipment of the 5X series of the fifth generation of European version of intelligent grinding mill working principle: 5X series of the fifth generation of European version of intelligent grinding mill is a new intelligent grinding equipment based on thirty years of research and development experience to draw on new grinding technology, with a special structure design, full thin oil lubrication system, low resistance curved air duct and many other independent patented technology property rights. The intelligent grinding mill with large capacity and low energy consumption is also the preferred equipment for large-scale mineral processing plant construction and intelligent production of environmental protection.

The 5X series European version mill is a vertical structure, mainly composed of the main machine, fan, powder selector, special dust collector, cyclone collector, piping device, motor and other equipment, supporting auxiliary equipment can choose crusher, elevator, belt machine, electromagnetic vibrating feeder, silo, control cabinet and so on.

The material is sent evenly to the grinding chamber of the main machine through the feeding device. Under the action of centrifugal force and shovel, the material is crushed by squeezing and grinding between the grinding rollers and grinding rings, and the crushed material is blown to the powder separator for sorting under the action of wind.

The whole airflow system of the mill is a closed cycle, circulating under negative pressure. Firstly, the airflow generated by the fan along with the material enters the cyclone powder collector through the duct, the powder collector separates the material from the airflow, and the airflow returns to the fan through the return air duct, forming an air circulation system; secondly, the excess gas and micro powder are sent to the dust collector for filtration through the duct, the dust is collected by the dust collector, and the remaining air is purified and discharged, effectively protecting the environment.

As a professional grinding equipment manufacturer, SMPCRUSHER has strong strength, exquisite technology, advanced technology and reliable and stable product quality. For the latest quotation of high-calcium stone powder production equipment, welcome to leave a message immediately!

Previous: SMP Crusher

Next: SMP Crusher

How much is a mobile crusher and what are the advantages of a mobile crusher

How much is a mobile crusher and what are the advantages of a mobile crusher Quartz stone dry sand production line process, suitable for processing quartz stone crusher

Quartz stone dry sand production line process, suitable for processing quartz stone crusher What are the full set of sand making equipment

What are the full set of sand making equipment Lithium pyroxene applied to crusher mill: opening a new chapter of efficient energy material processing

Lithium pyroxene applied to crusher mill: opening a new chapter of efficient energy material processing Lithium pyroxene can be used in which fields, recommend a lithium pyroxene grinding machine supplier

Lithium pyroxene can be used in which fields, recommend a lithium pyroxene grinding machine supplier How much is a mobile crusher and what are the advantages of a mobile crusher

How much is a mobile crusher and what are the advantages of a mobile crusher Quartz stone dry sand production line process, suitable for processing quartz stone crusher

Quartz stone dry sand production line process, suitable for processing quartz stone crusher What are the full set of sand making equipment

What are the full set of sand making equipment Lithium pyroxene applied to crusher mill: opening a new chapter of efficient energy material processing

Lithium pyroxene applied to crusher mill: opening a new chapter of efficient energy material processing Lithium pyroxene can be used in which fields, recommend a lithium pyroxene grinding machine supplier

Lithium pyroxene can be used in which fields, recommend a lithium pyroxene grinding machine supplier