The complete stone mill equipment includes stone crushing, screening, grinding equipment, which can be widely used in granite, limestone, quartzite, marble, potassium feldspar, pebbles and other non-metallic minerals with hardness less than 9.3,

The complete stone mill equipment includes stone crushing, screening, grinding equipment, which can be widely used in granite, limestone, quartzite, marble, potassium feldspar, pebbles and other non-metallic minerals with hardness less than 9.3, humidity less than 6% of the grinding process. According to the properties of the stone and the user's demand for the output of different, we for the entire production line equipment configuration is also a big difference, so how to choose a more suitable for their needs of stone grinding production line equipment? We deliberately based on the actual production of most users to integrate the following suggestions, I hope to help you.

First, the classification of stone grinding equipment

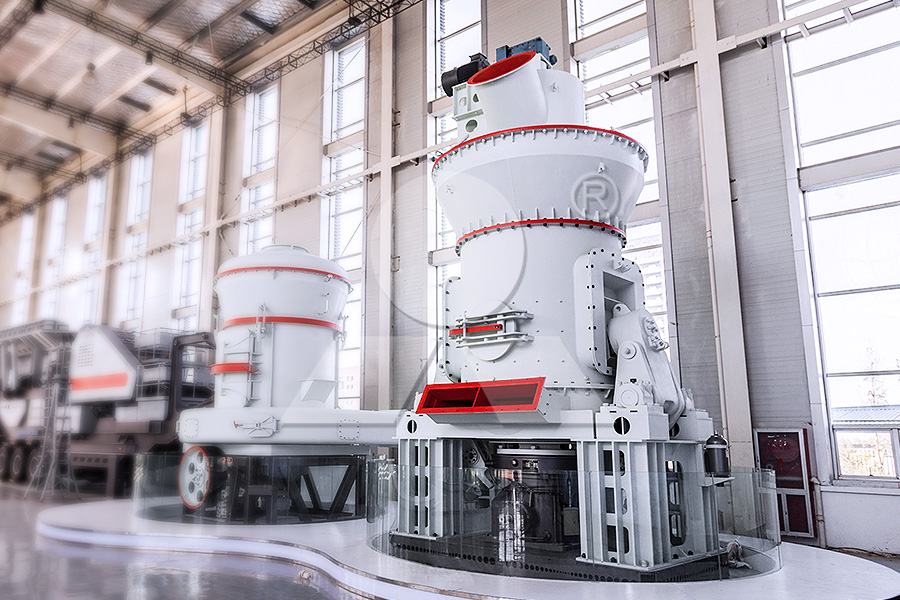

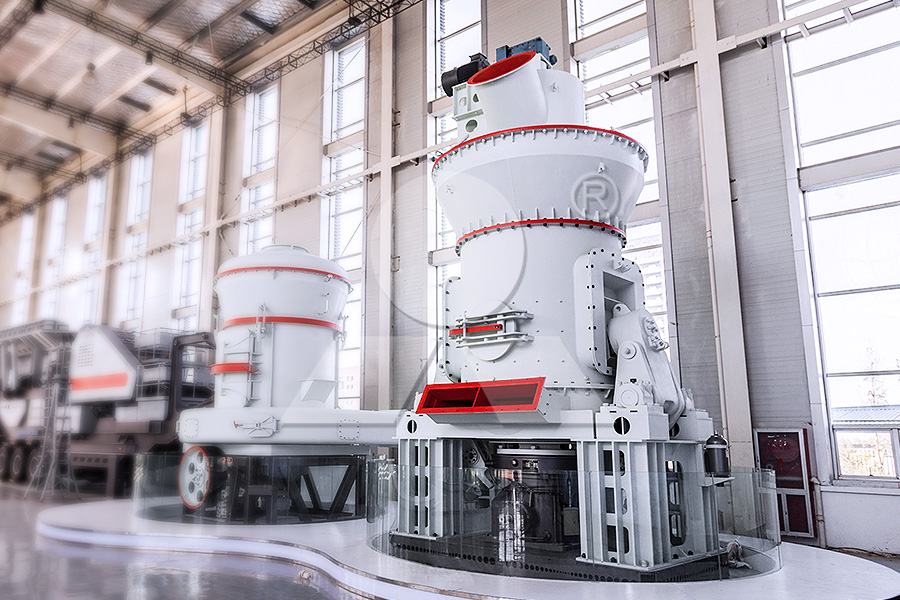

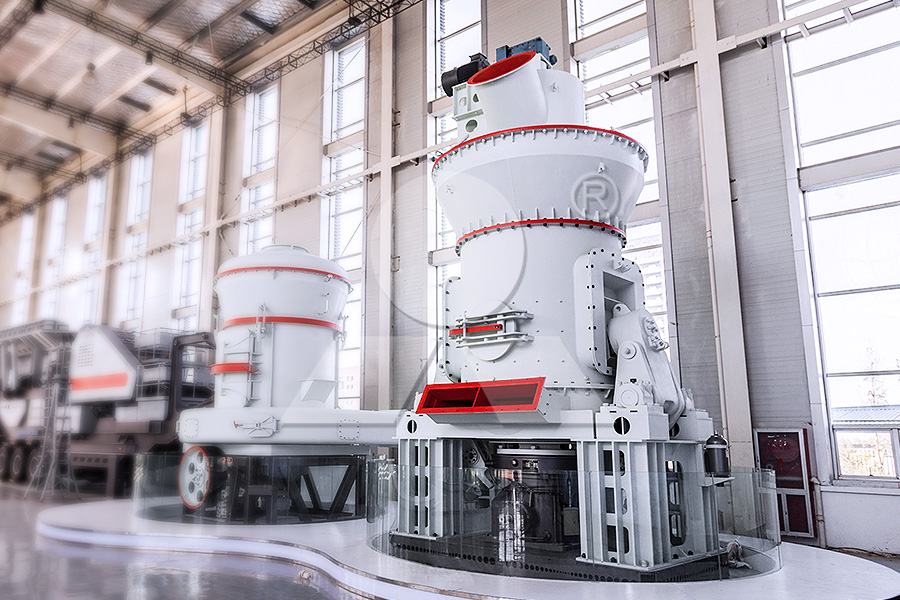

There are many kinds of stone grinding equipment, generally including coarse crushing equipment: jaw crusher, usually used for primary crushing of stone; fine crushing equipment: jaw crusher, cone crusher, impact crusher, hammer crusher, etc., usually these devices are used to secondary crushing of stone, crushing to the size of the grinding; grinding equipment: Raymond mill, ultra-fine mill, ultra-fine vertical mill, etc., used for stone grinding and processing; auxiliary equipment: Raymond mill, ultra-fine mill, ultra-fine vertical mill, etc., used to stone grinding and processing; auxiliary equipment: stone grinding mill, ultrafine mill, ultrafine vertical mill, etc. Grinding equipment: Raymond mill, ultra-fine mill, ultra-fine vertical mill, etc., used to grind stone; auxiliary equipment: vibrating feeder, circular vibrating screen, belt conveyor, dust collector and so on.

Second, stone milling equipment selection has a "good trick"

1, a clear understanding of the properties of the stone

Here the attributes of nature refers to the hardness, each machine can adapt to the hardness of different materials, such as high hardness of granite, pebbles, etc., we can usually choose the jaw crusher + cone crusher + grinding mill combination with, so that not only the crushing ratio is large, the quality of the product is also better. If users choose soft stone, such as limestone, coal, etc., we can choose the combination of jaw crusher + impact crusher + grinding mill, which can make the stone play a greater value. According to the stone hardness to choose the right machine to create greater value.

2, clear their demand for product quality

Some users of product quality requirements are more stringent, the machine has a higher standard, but such a powerful effect of the machine is more expensive, but the user does not have to worry, we through a reasonable combination of other equipment, not only can save the user's costs, reduce energy consumption, and can create a higher income for the user.

3, the user to understand their own production status quo

Each combination with the price difference is not small, and each manufacturer's capital also exists, so the user chooses to buy the equipment should be combined with their own production status quo, whether it is affordable, with a small investment to get big gains.

SMPCRUSHER is a high-tech company integrating R&D, production and distribution, and provides crusher, sand making, grinding equipment, mobile crushing station, etc. mature products and solutions used in aggregate, mining and waste recycling. At present, we have established cooperative relations with customers in more than 170 countries, and helped them plan reasonable programme and realize scientific process.

Previous: SMP Crusher

Next: SMP Crusher

The complete stone mill equipment includes stone crushing, screening, grinding equipment, which can be widely used in granite, limestone, quartzite, marble, potassium feldspar, pebbles and other non-metallic minerals with hardness less than 9.3,

The complete stone mill equipment includes stone crushing, screening, grinding equipment, which can be widely used in granite, limestone, quartzite, marble, potassium feldspar, pebbles and other non-metallic minerals with hardness less than 9.3, humidity less than 6% of the grinding process. According to the properties of the stone and the user's demand for the output of different, we for the entire production line equipment configuration is also a big difference, so how to choose a more suitable for their needs of stone grinding production line equipment? We deliberately based on the actual production of most users to integrate the following suggestions, I hope to help you.

First, the classification of stone grinding equipment

There are many kinds of stone grinding equipment, generally including coarse crushing equipment: jaw crusher, usually used for primary crushing of stone; fine crushing equipment: jaw crusher, cone crusher, impact crusher, hammer crusher, etc., usually these devices are used to secondary crushing of stone, crushing to the size of the grinding; grinding equipment: Raymond mill, ultra-fine mill, ultra-fine vertical mill, etc., used for stone grinding and processing; auxiliary equipment: Raymond mill, ultra-fine mill, ultra-fine vertical mill, etc., used to stone grinding and processing; auxiliary equipment: stone grinding mill, ultrafine mill, ultrafine vertical mill, etc. Grinding equipment: Raymond mill, ultra-fine mill, ultra-fine vertical mill, etc., used to grind stone; auxiliary equipment: vibrating feeder, circular vibrating screen, belt conveyor, dust collector and so on.

Second, stone milling equipment selection has a "good trick"

1, a clear understanding of the properties of the stone

Here the attributes of nature refers to the hardness, each machine can adapt to the hardness of different materials, such as high hardness of granite, pebbles, etc., we can usually choose the jaw crusher + cone crusher + grinding mill combination with, so that not only the crushing ratio is large, the quality of the product is also better. If users choose soft stone, such as limestone, coal, etc., we can choose the combination of jaw crusher + impact crusher + grinding mill, which can make the stone play a greater value. According to the stone hardness to choose the right machine to create greater value.

2, clear their demand for product quality

Some users of product quality requirements are more stringent, the machine has a higher standard, but such a powerful effect of the machine is more expensive, but the user does not have to worry, we through a reasonable combination of other equipment, not only can save the user's costs, reduce energy consumption, and can create a higher income for the user.

3, the user to understand their own production status quo

Each combination with the price difference is not small, and each manufacturer's capital also exists, so the user chooses to buy the equipment should be combined with their own production status quo, whether it is affordable, with a small investment to get big gains.

SMPCRUSHER is a high-tech company integrating R&D, production and distribution, and provides crusher, sand making, grinding equipment, mobile crushing station, etc. mature products and solutions used in aggregate, mining and waste recycling. At present, we have established cooperative relations with customers in more than 170 countries, and helped them plan reasonable programme and realize scientific process.

Previous: SMP Crusher

Next: SMP Crusher

Ore Raymond Mill, Ore Superfine Mill Price

Ore Raymond Mill, Ore Superfine Mill Price 1250 mesh calcium carbonate ultrafine grinding mill price fineness up to what mesh

1250 mesh calcium carbonate ultrafine grinding mill price fineness up to what mesh What are the easily overlooked faults of Raymond Mill

What are the easily overlooked faults of Raymond Mill Raymond mill choose different discharge fineness of the stone is not the same yield

Raymond mill choose different discharge fineness of the stone is not the same yield What to do when the mill is aging after a long period of use

What to do when the mill is aging after a long period of use Ore Raymond Mill, Ore Superfine Mill Price

Ore Raymond Mill, Ore Superfine Mill Price 1250 mesh calcium carbonate ultrafine grinding mill price fineness up to what mesh

1250 mesh calcium carbonate ultrafine grinding mill price fineness up to what mesh What are the easily overlooked faults of Raymond Mill

What are the easily overlooked faults of Raymond Mill Raymond mill choose different discharge fineness of the stone is not the same yield

Raymond mill choose different discharge fineness of the stone is not the same yield What to do when the mill is aging after a long period of use

What to do when the mill is aging after a long period of use