Lead-zinc ore, being a high-hardness ore, requires significantly different crushing and beneficiation processes compared to ordinary ores. So, what is the beneficiation process for lead-zinc ore? And what equipment should be selected?

Lead-zinc ore, being a high-hardness ore, requires significantly different crushing and beneficiation processes compared to ordinary ores. So, what is the beneficiation process for lead-zinc ore? And what equipment should be selected?

More Lead-Zinc Ore Crushing Equipment

Lead-Zinc Ore Processing Process

Lead-zinc ore processing mainly includes three steps: crushing, grinding, and beneficiation.

Crushing Process

Three-stage closed-circuit crushing is currently the most suitable crushing method for high-hardness lead-zinc ore. It effectively crushes and partially liberates the ore, thereby improving the efficiency of subsequent grinding.

Large pieces of lead-zinc ore are first evenly fed into a jaw crusher or a primary crushing mobile station via a vibrating feeder for initial crushing.

The coarsely crushed lead-zinc ore is screened by a vibrating screen and then conveyed by a belt conveyor to a single-cylinder hydraulic cone crusher for secondary crushing.

The secondary-crushed lead-zinc ore material is further fed into a multi-cylinder hydraulic cone crusher for fine crushing.

Grinding Process

Two-stage closed-circuit grinding allows for more thorough grinding of lead-zinc ore.

The 0-12 mm lead-zinc ore after screening is evenly fed into the grinding mill for grinding, and then screened by a spiral classifier. Material that does not meet the requirements is returned to the grinding mill for further grinding.

Mineral Processing Process

In recent years, mixed flotation has become one of the more successful new processes in lead-zinc ore beneficiation.

The ore powder meeting the beneficiation requirements is first fed into a magnetic separator for strong magnetic separation to remove impurities.

Then, the obtained ore powder is sent to a dryer for drying to obtain concentrate.

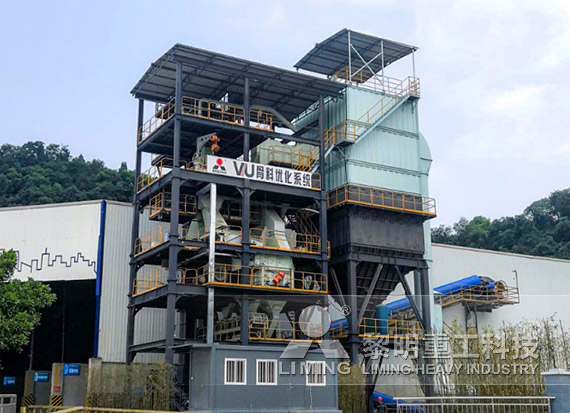

Lead-Zinc Ore Processing Case

A lead-zinc ore processing production line in Northeast China

Application Area: Metal Smelting

Processed Material: Lead-Zinc Ore

Output: 5000 tons/day

Equipment Configuration: HPT series cone crusher, jaw crusher

Customer Feedback

The purpose of processing lead-zinc ore is to smelt alloy materials. A complete mineral processing production line from Shibang Group was purchased for lead-zinc ore processing. The equipment is stable and reliable, and its output fully meets requirements. We have complete peace of mind using Shibang Group's equipment; engineers regularly visit the site to troubleshoot problems, ensuring worry-free production.

Through the above introduction, we believe you have a clearer understanding of lead-zinc ore processing technology and equipment selection. Choosing the right equipment and a scientific process flow can not only improve production efficiency but also ensure product quality. Shibang Group will continue to provide high-quality equipment and professional services to help your lead-zinc ore processing business achieve greater success.

Previous: SMP Crusher

Next: SMP Crusher

Lead-zinc ore, being a high-hardness ore, requires significantly different crushing and beneficiation processes compared to ordinary ores. So, what is the beneficiation process for lead-zinc ore? And what equipment should be selected?

Lead-zinc ore, being a high-hardness ore, requires significantly different crushing and beneficiation processes compared to ordinary ores. So, what is the beneficiation process for lead-zinc ore? And what equipment should be selected?

More Lead-Zinc Ore Crushing Equipment

Lead-Zinc Ore Processing Process

Lead-zinc ore processing mainly includes three steps: crushing, grinding, and beneficiation.

Crushing Process

Three-stage closed-circuit crushing is currently the most suitable crushing method for high-hardness lead-zinc ore. It effectively crushes and partially liberates the ore, thereby improving the efficiency of subsequent grinding.

Large pieces of lead-zinc ore are first evenly fed into a jaw crusher or a primary crushing mobile station via a vibrating feeder for initial crushing.

The coarsely crushed lead-zinc ore is screened by a vibrating screen and then conveyed by a belt conveyor to a single-cylinder hydraulic cone crusher for secondary crushing.

The secondary-crushed lead-zinc ore material is further fed into a multi-cylinder hydraulic cone crusher for fine crushing.

Grinding Process

Two-stage closed-circuit grinding allows for more thorough grinding of lead-zinc ore.

The 0-12 mm lead-zinc ore after screening is evenly fed into the grinding mill for grinding, and then screened by a spiral classifier. Material that does not meet the requirements is returned to the grinding mill for further grinding.

Mineral Processing Process

In recent years, mixed flotation has become one of the more successful new processes in lead-zinc ore beneficiation.

The ore powder meeting the beneficiation requirements is first fed into a magnetic separator for strong magnetic separation to remove impurities.

Then, the obtained ore powder is sent to a dryer for drying to obtain concentrate.

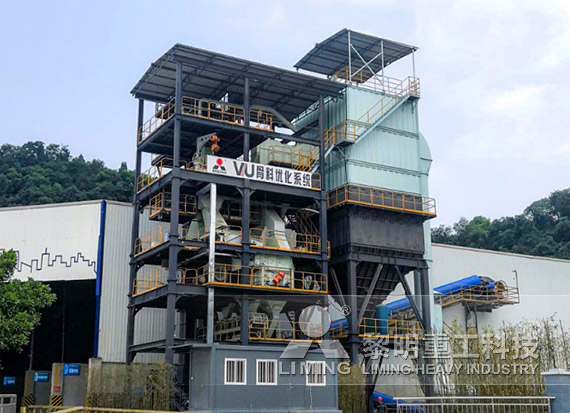

Lead-Zinc Ore Processing Case

A lead-zinc ore processing production line in Northeast China

Application Area: Metal Smelting

Processed Material: Lead-Zinc Ore

Output: 5000 tons/day

Equipment Configuration: HPT series cone crusher, jaw crusher

Customer Feedback

The purpose of processing lead-zinc ore is to smelt alloy materials. A complete mineral processing production line from Shibang Group was purchased for lead-zinc ore processing. The equipment is stable and reliable, and its output fully meets requirements. We have complete peace of mind using Shibang Group's equipment; engineers regularly visit the site to troubleshoot problems, ensuring worry-free production.

Through the above introduction, we believe you have a clearer understanding of lead-zinc ore processing technology and equipment selection. Choosing the right equipment and a scientific process flow can not only improve production efficiency but also ensure product quality. Shibang Group will continue to provide high-quality equipment and professional services to help your lead-zinc ore processing business achieve greater success.

Previous: SMP Crusher

Next: SMP Crusher

How to Choose a Sand and Gravel Production Line Manufacturer

How to Choose a Sand and Gravel Production Line Manufacturer Configuration scheme for large-scale sand and gravel production line: 800-900tph limestone crushing production line

Configuration scheme for large-scale sand and gravel production line: 800-900tph limestone crushing production line Analysis of the distribution of sand and gravel mines in Guizhou Province and its surrounding areas, covering 1,582 sand and gravel mining rights.

Analysis of the distribution of sand and gravel mines in Guizhou Province and its surrounding areas, covering 1,582 sand and gravel mining rights. High-efficiency iron ore crushing equipment helps mining enterprises achieve high output and low consumption.

High-efficiency iron ore crushing equipment helps mining enterprises achieve high output and low consumption. Environmental impact assessment announcement for Hebei Chengde Zhuhe Mining project with a total investment of 650 million yuan.

Environmental impact assessment announcement for Hebei Chengde Zhuhe Mining project with a total investment of 650 million yuan. How to Choose a Sand and Gravel Production Line Manufacturer

How to Choose a Sand and Gravel Production Line Manufacturer Configuration scheme for large-scale sand and gravel production line: 800-900tph limestone crushing production line

Configuration scheme for large-scale sand and gravel production line: 800-900tph limestone crushing production line Analysis of the distribution of sand and gravel mines in Guizhou Province and its surrounding areas, covering 1,582 sand and gravel mining rights.

Analysis of the distribution of sand and gravel mines in Guizhou Province and its surrounding areas, covering 1,582 sand and gravel mining rights. High-efficiency iron ore crushing equipment helps mining enterprises achieve high output and low consumption.

High-efficiency iron ore crushing equipment helps mining enterprises achieve high output and low consumption. Environmental impact assessment announcement for Hebei Chengde Zhuhe Mining project with a total investment of 650 million yuan.

Environmental impact assessment announcement for Hebei Chengde Zhuhe Mining project with a total investment of 650 million yuan.