Nature of iron oxide iron oxide is reddish brown powder, soluble in hydrochloric acid, melting point 1565 ° C, boiling point 3414 ° C, density 5.24 g/cm³, insoluble in water, do not react with water, is the main component of rust, according to the c

Nature of iron oxide iron oxide is reddish brown powder, soluble in hydrochloric acid, melting point 1565 ° C, boiling point 3414 ° C, density 5.24 g/cm³, insoluble in water, do not react with water, is the main component of rust, according to the color is divided into iron oxide red, iron oxide yellow, iron oxide black, commonly used in pigments to use.

Application fields

1、As a pigment, used for coloring paint, rubber, plastic, construction, etc. It is an inorganic pigment, and is used as antirust pigment in the paint industry.

2、Used in electronic industry, communication machine, TV, computer and other magnetic raw materials and line output transformer, switching power supply and its high U and high UQ ferrite core.

3、Used as analytical reagent, catalyst and polishing agent, also used for pigment dosage.

4、It is used for coloring the outer sugar coating of all kinds of tablets and pills.

5、Used in the production of reducing agent, polishing agent, catalyst and so on.

Iron oxide preparation and processing

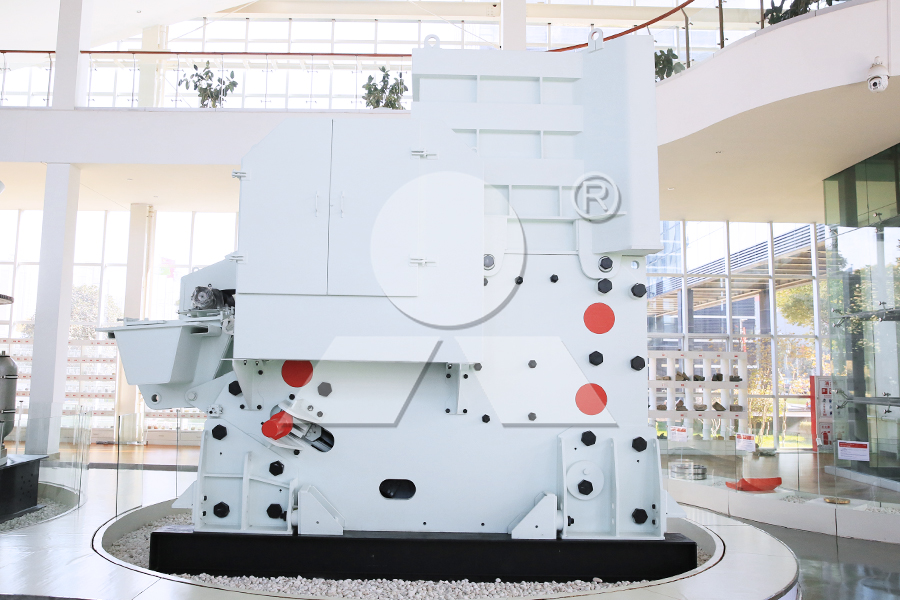

Iron oxide preparation method has wet and dry method, when used as pigment, can adopt wet method, wet method products crystallization fine, soft particles, easier to grind; when used for magnetic materials, polishing and grinding materials, adopt dry method, dry method products crystallization, hard particles. In the dry production, need to cool the crystallization, dehydration and drying, after grinding and then calcined and then washed, dried, crushed to produce iron oxide red products, etc., which can not be separated from the crusher, iron oxide rotary kiln, cooler, mill, dryer and other equipment to greatly help. Wet method is the use of chemical reaction for the preparation and processing of iron oxide.

Related equipment:

Rotary kiln

Grinding Mill

Dryer

Previous: SMP Crusher

Next: SMP Crusher

Nature of iron oxide iron oxide is reddish brown powder, soluble in hydrochloric acid, melting point 1565 ° C, boiling point 3414 ° C, density 5.24 g/cm³, insoluble in water, do not react with water, is the main component of rust, according to the c

Nature of iron oxide iron oxide is reddish brown powder, soluble in hydrochloric acid, melting point 1565 ° C, boiling point 3414 ° C, density 5.24 g/cm³, insoluble in water, do not react with water, is the main component of rust, according to the color is divided into iron oxide red, iron oxide yellow, iron oxide black, commonly used in pigments to use.

Application fields

1、As a pigment, used for coloring paint, rubber, plastic, construction, etc. It is an inorganic pigment, and is used as antirust pigment in the paint industry.

2、Used in electronic industry, communication machine, TV, computer and other magnetic raw materials and line output transformer, switching power supply and its high U and high UQ ferrite core.

3、Used as analytical reagent, catalyst and polishing agent, also used for pigment dosage.

4、It is used for coloring the outer sugar coating of all kinds of tablets and pills.

5、Used in the production of reducing agent, polishing agent, catalyst and so on.

Iron oxide preparation and processing

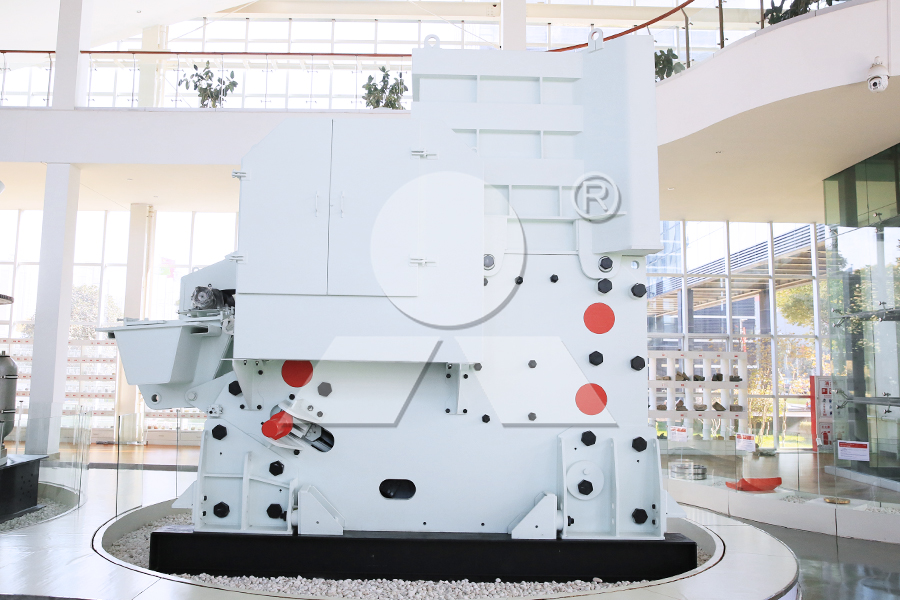

Iron oxide preparation method has wet and dry method, when used as pigment, can adopt wet method, wet method products crystallization fine, soft particles, easier to grind; when used for magnetic materials, polishing and grinding materials, adopt dry method, dry method products crystallization, hard particles. In the dry production, need to cool the crystallization, dehydration and drying, after grinding and then calcined and then washed, dried, crushed to produce iron oxide red products, etc., which can not be separated from the crusher, iron oxide rotary kiln, cooler, mill, dryer and other equipment to greatly help. Wet method is the use of chemical reaction for the preparation and processing of iron oxide.

Related equipment:

Rotary kiln

Grinding Mill

Dryer

Previous: SMP Crusher

Next: SMP Crusher