With the increasing demand for sand and gravel aggregates, traditional small-scale, low-capacity, and highly polluting production models are no longer able to meet market demands. Large-scale, high-efficiency, and environmentally friendly production li

With the increasing demand for sand and gravel aggregates, traditional small-scale, low-capacity, and highly polluting production models are no longer able to meet market demands. Large-scale, high-efficiency, and environmentally friendly production lines have become the new trend in the industry. Below, we take a sand and gravel aggregate production line with a capacity of up to 2000 t/h as an example to see how it achieves both efficient production and environmental protection.

More Sand Production Line Project Cases

Project Background

This production line mainly utilizes the associated minerals from limestone mining for cement production as raw materials. Through advanced production processes and technologies, it achieves objectives such as mud removal, dust removal, multi-stage crushing and screening, aggregate shaping, and simultaneous production of sand and gravel. It also employs environmentally friendly technologies such as powder recovery, storage, and utilization to ensure a green and environmentally friendly production process.

Solution Selection

Facing the challenge of crushing soft rocks like limestone, the project team conducted in-depth research and on-site investigations, ultimately choosing a jaw crusher + impact crusher crushing solution. Although this solution has a slightly higher investment cost, it effectively avoids the problems of large crushing ratio, excessive fines, and low yield associated with hammer crusher solutions, while also reducing the higher power consumption and wear part operating costs of the impact crusher + impact crusher solution.

Process Flow

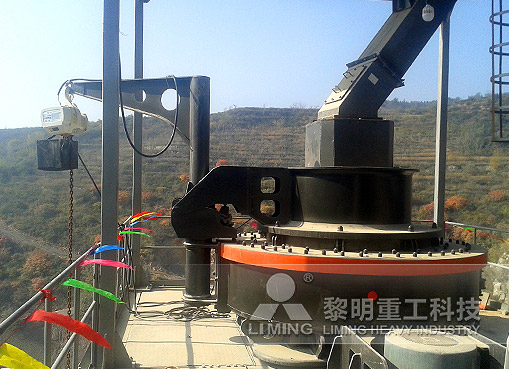

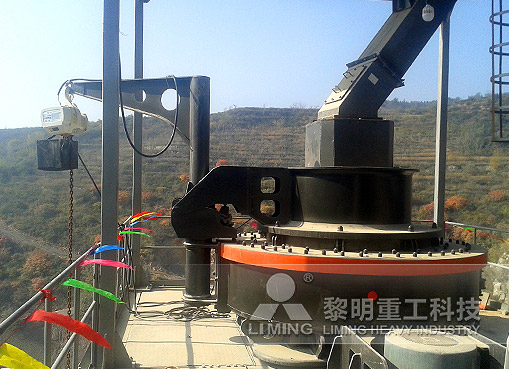

The production line adopts a complete process flow, including eight major stages: building aggregate and manufactured sand jaw crushing system, mud removal, screening and conveying, building aggregate and manufactured sand fine crushing impact crushing system, primary screening system, secondary screening system, manufactured sand vertical shaft crushing system, powder selection and conveying system, and storage and loading system.

Each stage is equipped with advanced equipment and technology to ensure the continuity and efficiency of the production process. At the same time, through reasonable process flow design, it achieves maximum utilization of raw materials and diversified product output.

Environmental Protection Measures

During the production process, this production line focuses on implementing environmental protection measures. Through technologies such as mud removal and dust removal, it effectively reduces dust pollution during the production process. It also adopts environmentally friendly technologies such as powder recovery, storage, and utilization to achieve resource utilization of waste and reduce emissions.

After actual operation verification, this production line has demonstrated excellent performance and stable operation. It not only achieved high-yield and high-efficiency production goals but also met the requirements of green environmental protection. The product quality is stable and reliable, and it is highly welcomed by the market. Conclusion

This case study of a 2000 t/h manufactured sand and aggregate production line fully demonstrates the development trends and advantages of large-scale, high-efficiency, and environmentally friendly production lines. Through the implementation of advanced production processes and environmental protection measures, a win-win situation of both economic and ecological benefits has been achieved.

Previous: SMP Crusher

Next: SMP Crusher

With the increasing demand for sand and gravel aggregates, traditional small-scale, low-capacity, and highly polluting production models are no longer able to meet market demands. Large-scale, high-efficiency, and environmentally friendly production li

With the increasing demand for sand and gravel aggregates, traditional small-scale, low-capacity, and highly polluting production models are no longer able to meet market demands. Large-scale, high-efficiency, and environmentally friendly production lines have become the new trend in the industry. Below, we take a sand and gravel aggregate production line with a capacity of up to 2000 t/h as an example to see how it achieves both efficient production and environmental protection.

More Sand Production Line Project Cases

Project Background

This production line mainly utilizes the associated minerals from limestone mining for cement production as raw materials. Through advanced production processes and technologies, it achieves objectives such as mud removal, dust removal, multi-stage crushing and screening, aggregate shaping, and simultaneous production of sand and gravel. It also employs environmentally friendly technologies such as powder recovery, storage, and utilization to ensure a green and environmentally friendly production process.

Solution Selection

Facing the challenge of crushing soft rocks like limestone, the project team conducted in-depth research and on-site investigations, ultimately choosing a jaw crusher + impact crusher crushing solution. Although this solution has a slightly higher investment cost, it effectively avoids the problems of large crushing ratio, excessive fines, and low yield associated with hammer crusher solutions, while also reducing the higher power consumption and wear part operating costs of the impact crusher + impact crusher solution.

Process Flow

The production line adopts a complete process flow, including eight major stages: building aggregate and manufactured sand jaw crushing system, mud removal, screening and conveying, building aggregate and manufactured sand fine crushing impact crushing system, primary screening system, secondary screening system, manufactured sand vertical shaft crushing system, powder selection and conveying system, and storage and loading system.

Each stage is equipped with advanced equipment and technology to ensure the continuity and efficiency of the production process. At the same time, through reasonable process flow design, it achieves maximum utilization of raw materials and diversified product output.

Environmental Protection Measures

During the production process, this production line focuses on implementing environmental protection measures. Through technologies such as mud removal and dust removal, it effectively reduces dust pollution during the production process. It also adopts environmentally friendly technologies such as powder recovery, storage, and utilization to achieve resource utilization of waste and reduce emissions.

After actual operation verification, this production line has demonstrated excellent performance and stable operation. It not only achieved high-yield and high-efficiency production goals but also met the requirements of green environmental protection. The product quality is stable and reliable, and it is highly welcomed by the market. Conclusion

This case study of a 2000 t/h manufactured sand and aggregate production line fully demonstrates the development trends and advantages of large-scale, high-efficiency, and environmentally friendly production lines. Through the implementation of advanced production processes and environmental protection measures, a win-win situation of both economic and ecological benefits has been achieved.

Previous: SMP Crusher

Next: SMP Crusher

A sand and gravel project exceeding 10 billion RMB has commenced in Tongcheng, Anhui Province, and Shibang Group analyzes this new chapter in green mining.

A sand and gravel project exceeding 10 billion RMB has commenced in Tongcheng, Anhui Province, and Shibang Group analyzes this new chapter in green mining. Shaanxi Jiaokong Hanzhong is collaborating with Shibang to build a construction aggregate production line with an annual capacity of 3 million tons.

Shaanxi Jiaokong Hanzhong is collaborating with Shibang to build a construction aggregate production line with an annual capacity of 3 million tons. What equipment should be chosen for a sand and gravel production line with a capacity of 500 tons per hour?

What equipment should be chosen for a sand and gravel production line with a capacity of 500 tons per hour? China Power Construction (PCC): In 2023, its sand and gravel business generated 4.63 billion yuan in revenue and sold 90 million tons! Its designed production capacity reached 505 million tons.

China Power Construction (PCC): In 2023, its sand and gravel business generated 4.63 billion yuan in revenue and sold 90 million tons! Its designed production capacity reached 505 million tons. How to choose a mining crusher manufacturer?

How to choose a mining crusher manufacturer? A sand and gravel project exceeding 10 billion RMB has commenced in Tongcheng, Anhui Province, and Shibang Group analyzes this new chapter in green mining.

A sand and gravel project exceeding 10 billion RMB has commenced in Tongcheng, Anhui Province, and Shibang Group analyzes this new chapter in green mining. Shaanxi Jiaokong Hanzhong is collaborating with Shibang to build a construction aggregate production line with an annual capacity of 3 million tons.

Shaanxi Jiaokong Hanzhong is collaborating with Shibang to build a construction aggregate production line with an annual capacity of 3 million tons. What equipment should be chosen for a sand and gravel production line with a capacity of 500 tons per hour?

What equipment should be chosen for a sand and gravel production line with a capacity of 500 tons per hour? China Power Construction (PCC): In 2023, its sand and gravel business generated 4.63 billion yuan in revenue and sold 90 million tons! Its designed production capacity reached 505 million tons.

China Power Construction (PCC): In 2023, its sand and gravel business generated 4.63 billion yuan in revenue and sold 90 million tons! Its designed production capacity reached 505 million tons. How to choose a mining crusher manufacturer?

How to choose a mining crusher manufacturer?