In the field of building materials, the quality of machine-made sand directly affects the performance of building materials such as concrete. Traditional sand making technology has many drawbacks, such as more coarse particles, fewer fine particles, un

In the field of building materials, the quality of machine-made sand directly affects the performance of building materials such as concrete. Traditional sand making technology has many drawbacks, such as more coarse particles, fewer fine particles, unreasonable grading, high stone powder content, rough and angular surface, etc., which seriously restrict the quality improvement of machine-made sand. Liming Heavy Industry's VU aggregate optimization system is an optimization masterpiece that came into being to address these problems.

The VU aggregate optimization system adopts a highly intensive tower-style fully enclosed layout. This innovative design integrates sand screening, particle shape optimization, stone powder control, grading adjustment, moisture content control, and environmental protection treatment. In terms of particle shape optimization, innovative grinding technology and waterfall shaping technology are used to make the finished sand particle shape mainly high squareness and sphericity, greatly reducing surface edges and burrs, reducing surface area and porosity, and significantly improving fluidity. In terms of grading adjustment, through comprehensive crushing and grinding and flexible and controllable screening design, the grading of finished sand is continuous and adjustable, the proportion of 0.15-0.6mm fine sand is greatly increased, and the proportion of 2.36-4.75mm coarse sand is reduced, which fully complies with the industry standard restrictions such as ASTM C33 in the United States, JGJ52 Zone 2 in China and IS383 Zone 2 in India. At the same time, the wind selection technology is combined with the vibration screening technology to adjust the total air volume online, accurately adjust the powder content of the finished sand and fine-tune the fineness modulus.

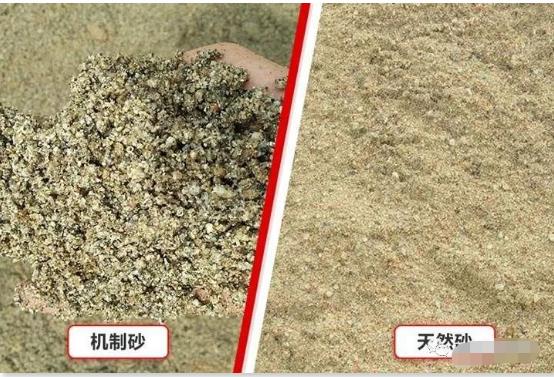

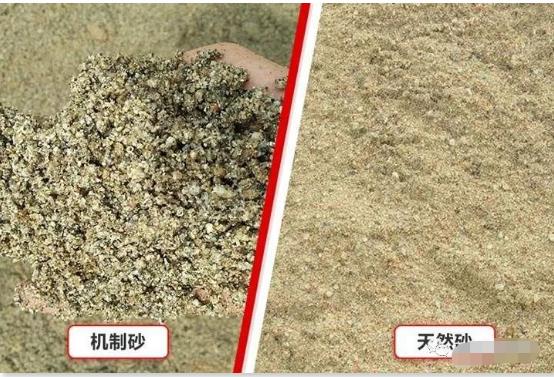

After being processed by the VU aggregate optimization system, even cheap and easily available raw materials such as stone chips and melon stones can produce high-quality finished sand with reasonable grading, rounded particles and controllable powder content, as well as dry, clean, and uniformly recyclable high-value-added stone powder. Taking a real project as an example, after using the VU aggregate optimization system, the quality of machine-made sand is comparable to that of natural sand. In concrete production, it not only improves the working performance and strength of concrete, but also saves the amount of cement and admixtures, reduces production costs for enterprises, and improves economic benefits.

It can be seen that the VU aggregate optimization system has successfully solved the problems of traditional sand making through a series of optimization measures, becoming a successful example of product optimization, and creating new opportunities and value for the development of the sandstone, cement, and concrete industry chain.

Previous: SMP Crusher

Next: SMP Crusher

In the field of building materials, the quality of machine-made sand directly affects the performance of building materials such as concrete. Traditional sand making technology has many drawbacks, such as more coarse particles, fewer fine particles, un

In the field of building materials, the quality of machine-made sand directly affects the performance of building materials such as concrete. Traditional sand making technology has many drawbacks, such as more coarse particles, fewer fine particles, unreasonable grading, high stone powder content, rough and angular surface, etc., which seriously restrict the quality improvement of machine-made sand. Liming Heavy Industry's VU aggregate optimization system is an optimization masterpiece that came into being to address these problems.

The VU aggregate optimization system adopts a highly intensive tower-style fully enclosed layout. This innovative design integrates sand screening, particle shape optimization, stone powder control, grading adjustment, moisture content control, and environmental protection treatment. In terms of particle shape optimization, innovative grinding technology and waterfall shaping technology are used to make the finished sand particle shape mainly high squareness and sphericity, greatly reducing surface edges and burrs, reducing surface area and porosity, and significantly improving fluidity. In terms of grading adjustment, through comprehensive crushing and grinding and flexible and controllable screening design, the grading of finished sand is continuous and adjustable, the proportion of 0.15-0.6mm fine sand is greatly increased, and the proportion of 2.36-4.75mm coarse sand is reduced, which fully complies with the industry standard restrictions such as ASTM C33 in the United States, JGJ52 Zone 2 in China and IS383 Zone 2 in India. At the same time, the wind selection technology is combined with the vibration screening technology to adjust the total air volume online, accurately adjust the powder content of the finished sand and fine-tune the fineness modulus.

After being processed by the VU aggregate optimization system, even cheap and easily available raw materials such as stone chips and melon stones can produce high-quality finished sand with reasonable grading, rounded particles and controllable powder content, as well as dry, clean, and uniformly recyclable high-value-added stone powder. Taking a real project as an example, after using the VU aggregate optimization system, the quality of machine-made sand is comparable to that of natural sand. In concrete production, it not only improves the working performance and strength of concrete, but also saves the amount of cement and admixtures, reduces production costs for enterprises, and improves economic benefits.

It can be seen that the VU aggregate optimization system has successfully solved the problems of traditional sand making through a series of optimization measures, becoming a successful example of product optimization, and creating new opportunities and value for the development of the sandstone, cement, and concrete industry chain.

Previous: SMP Crusher

Next: SMP Crusher

Liming Heavy Industry Mobile Crushing Station: The Optimization and Upgrading Road to Break Through Bottlenecks

Liming Heavy Industry Mobile Crushing Station: The Optimization and Upgrading Road to Break Through Bottlenecks Gravel production line: optimization and upgrading, new vitality

Gravel production line: optimization and upgrading, new vitality Is it better to choose a single-cylinder or multi-cylinder cone crusher?

Is it better to choose a single-cylinder or multi-cylinder cone crusher? Guide to choosing and avoiding pitfalls in sand and gravel mining equipment: these details determine production efficiency

Guide to choosing and avoiding pitfalls in sand and gravel mining equipment: these details determine production efficiency How to choose the right core equipment for sand and gravel mines under the wave of intelligence

How to choose the right core equipment for sand and gravel mines under the wave of intelligence Liming Heavy Industry Mobile Crushing Station: The Optimization and Upgrading Road to Break Through Bottlenecks

Liming Heavy Industry Mobile Crushing Station: The Optimization and Upgrading Road to Break Through Bottlenecks Gravel production line: optimization and upgrading, new vitality

Gravel production line: optimization and upgrading, new vitality Is it better to choose a single-cylinder or multi-cylinder cone crusher?

Is it better to choose a single-cylinder or multi-cylinder cone crusher? Guide to choosing and avoiding pitfalls in sand and gravel mining equipment: these details determine production efficiency

Guide to choosing and avoiding pitfalls in sand and gravel mining equipment: these details determine production efficiency How to choose the right core equipment for sand and gravel mines under the wave of intelligence

How to choose the right core equipment for sand and gravel mines under the wave of intelligence