With the growth of demand for sand and gravel aggregate, the scale of new sand and gravel production line is expanding. Product quality, scientific planning, equipment selection, and supporting mine construction are the keys to ensure the efficient, st

With the growth of demand for sand and gravel aggregate, the scale of new sand and gravel production line is expanding. Product quality, scientific planning, equipment selection, and supporting mine construction are the keys to ensure the efficient, stable and green operation of the project. Scientific planning and reasonable layout from various aspects are needed to meet the market demand.

With the rapid development of construction, roads and other infrastructure, the demand for sand and gravel aggregate is growing. Nowadays, the scale of the new sand and gravel production line is generally above one million tonnes per year, and there is even a super production line of 10 million tonnes emerging. In order to ensure efficient, stable and green operation of the project, the following points are worth focusing on at the early stage of new project construction.

First, product quality is the lifeline

In the competitive market, product quality is the foundation of the enterprise. High-quality aggregates should not only meet the national standards, but also meet the market demand. Especially the mechanism of sand products, its particle shape, grading and soil content and other indicators need to be strictly controlled. High-quality aggregates not only require good particle shape and grading, but also need to meet the requirements of commercial concrete and ready-mixed mortar sand. At the same time, according to the climate and geological conditions of different regions, the production process should be reasonably adjusted to ensure stable and reliable product quality.

Second, the construction of the production line should be scientifically planned

The new sand and gravel production line needs to be scientifically planned from the choice of mine site, plant layout, process programme to determine, equipment selection and other aspects. First of all, the process should be simple and efficient, easy to use and maintain equipment. Secondly, improve the level of automation and intelligence, reduce manpower investment, and improve the operation rate of equipment. Finally, the production line must meet the requirements of environmental protection and realise green production. It is recommended to choose an experienced design institute for the overall planning and design of the project to ensure the smooth progress of the project.

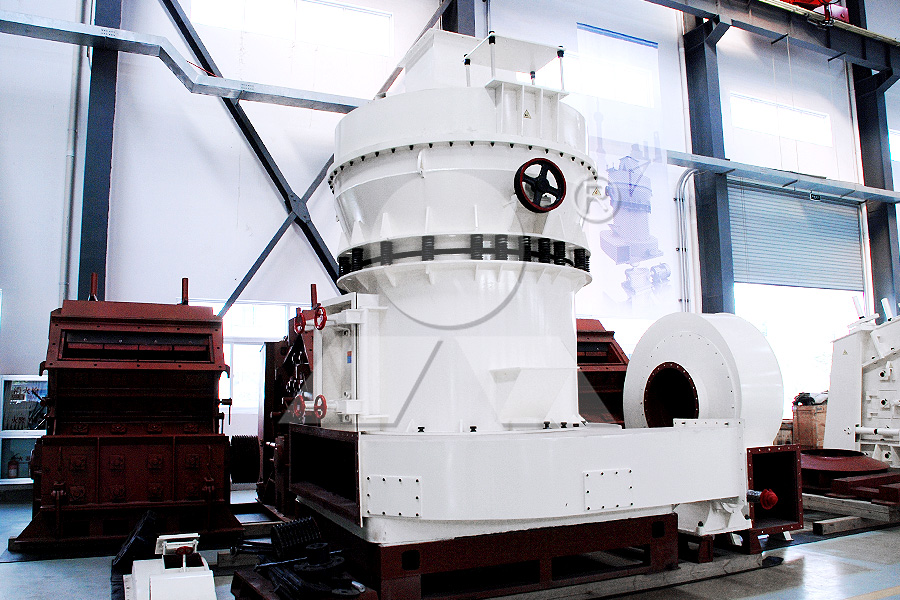

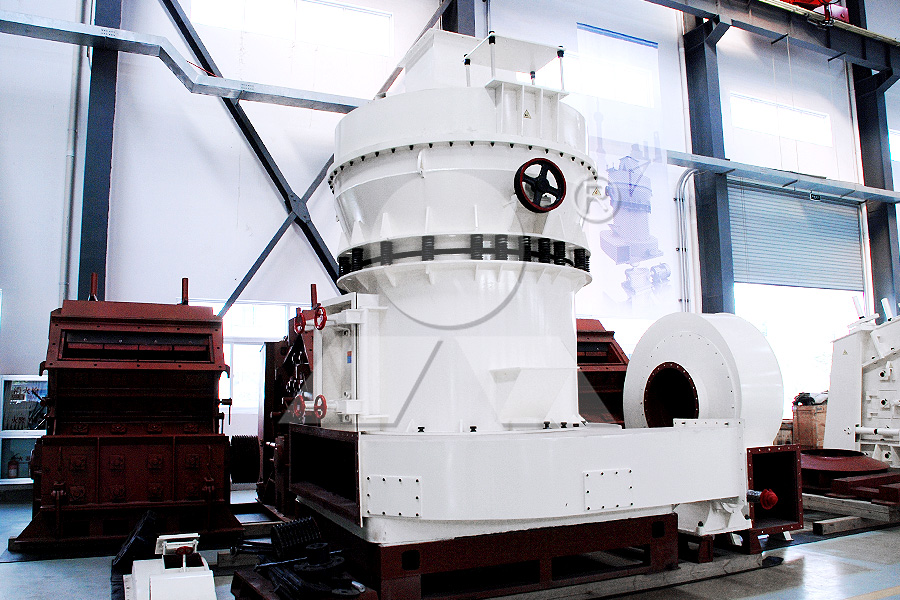

Third, equipment selection should be reasonable

Equipment selection is directly related to the operating effect of the production line. Selection, need to fully consider the physical properties of raw materials, production scale, product requirements and other factors. For hardness, abrasive index of raw materials, it is recommended to choose wear-resistant, durable equipment. At the same time, avoid directly copying the equipment selection programme of other enterprises to ensure that the equipment selection meets the actual production requirements.

Fourth, supporting mine construction should be standardised

Supporting mine construction is an important part of the gravel production line. When selecting the site, it should be selected according to the type of products planned and market demand. Priority should be given to the use of mine stripping waste rock or mineral processing tailings and other resources. Meanwhile, mine construction should comply with relevant national standards to achieve green and orderly mining. The ultimate goal is to create a green, environmentally friendly and efficient mine to provide stable and reliable raw material support for sand and gravel production.

In short, the new sand and gravel production line needs to be scientifically planned and reasonably laid out in terms of product quality, production line construction, equipment selection, supporting mine construction and other aspects. Only in this way can we ensure that the project runs efficiently, stably and greenly to meet the market demand.

Previous: SMP Crusher

Next: SMP Crusher

With the growth of demand for sand and gravel aggregate, the scale of new sand and gravel production line is expanding. Product quality, scientific planning, equipment selection, and supporting mine construction are the keys to ensure the efficient, st

With the growth of demand for sand and gravel aggregate, the scale of new sand and gravel production line is expanding. Product quality, scientific planning, equipment selection, and supporting mine construction are the keys to ensure the efficient, stable and green operation of the project. Scientific planning and reasonable layout from various aspects are needed to meet the market demand.

With the rapid development of construction, roads and other infrastructure, the demand for sand and gravel aggregate is growing. Nowadays, the scale of the new sand and gravel production line is generally above one million tonnes per year, and there is even a super production line of 10 million tonnes emerging. In order to ensure efficient, stable and green operation of the project, the following points are worth focusing on at the early stage of new project construction.

First, product quality is the lifeline

In the competitive market, product quality is the foundation of the enterprise. High-quality aggregates should not only meet the national standards, but also meet the market demand. Especially the mechanism of sand products, its particle shape, grading and soil content and other indicators need to be strictly controlled. High-quality aggregates not only require good particle shape and grading, but also need to meet the requirements of commercial concrete and ready-mixed mortar sand. At the same time, according to the climate and geological conditions of different regions, the production process should be reasonably adjusted to ensure stable and reliable product quality.

Second, the construction of the production line should be scientifically planned

The new sand and gravel production line needs to be scientifically planned from the choice of mine site, plant layout, process programme to determine, equipment selection and other aspects. First of all, the process should be simple and efficient, easy to use and maintain equipment. Secondly, improve the level of automation and intelligence, reduce manpower investment, and improve the operation rate of equipment. Finally, the production line must meet the requirements of environmental protection and realise green production. It is recommended to choose an experienced design institute for the overall planning and design of the project to ensure the smooth progress of the project.

Third, equipment selection should be reasonable

Equipment selection is directly related to the operating effect of the production line. Selection, need to fully consider the physical properties of raw materials, production scale, product requirements and other factors. For hardness, abrasive index of raw materials, it is recommended to choose wear-resistant, durable equipment. At the same time, avoid directly copying the equipment selection programme of other enterprises to ensure that the equipment selection meets the actual production requirements.

Fourth, supporting mine construction should be standardised

Supporting mine construction is an important part of the gravel production line. When selecting the site, it should be selected according to the type of products planned and market demand. Priority should be given to the use of mine stripping waste rock or mineral processing tailings and other resources. Meanwhile, mine construction should comply with relevant national standards to achieve green and orderly mining. The ultimate goal is to create a green, environmentally friendly and efficient mine to provide stable and reliable raw material support for sand and gravel production.

In short, the new sand and gravel production line needs to be scientifically planned and reasonably laid out in terms of product quality, production line construction, equipment selection, supporting mine construction and other aspects. Only in this way can we ensure that the project runs efficiently, stably and greenly to meet the market demand.

Previous: SMP Crusher

Next: SMP Crusher

How to make granite sand and how to choose 1000 tons of granite fine sand equipment per hour

How to make granite sand and how to choose 1000 tons of granite fine sand equipment per hour What are the precautions for choosing river pebble sand making machine

What are the precautions for choosing river pebble sand making machine Introduction to the key points of daily maintenance of sand making machine

Introduction to the key points of daily maintenance of sand making machine Why is granite difficult to crush and the construction plan of a 300 tons per hour granite crushing production line

Why is granite difficult to crush and the construction plan of a 300 tons per hour granite crushing production line What are the factors that affect the price of sand making equipment in the sand and gravel production line?

What are the factors that affect the price of sand making equipment in the sand and gravel production line? How to make granite sand and how to choose 1000 tons of granite fine sand equipment per hour

How to make granite sand and how to choose 1000 tons of granite fine sand equipment per hour What are the precautions for choosing river pebble sand making machine

What are the precautions for choosing river pebble sand making machine Introduction to the key points of daily maintenance of sand making machine

Introduction to the key points of daily maintenance of sand making machine Why is granite difficult to crush and the construction plan of a 300 tons per hour granite crushing production line

Why is granite difficult to crush and the construction plan of a 300 tons per hour granite crushing production line What are the factors that affect the price of sand making equipment in the sand and gravel production line?

What are the factors that affect the price of sand making equipment in the sand and gravel production line?