The dry sand making process does not require water washing, is environmentally friendly and water-saving, and the finished sand has excellent quality, full grain shape, reasonable gradation, and recyclable stone powder. The production cost is lower, wh

The dry sand making process does not require water washing, is environmentally friendly and water-saving, and the finished sand has excellent quality, full grain shape, reasonable gradation, and recyclable stone powder. The production cost is lower, which is especially suitable for arid areas.

Dry sand making is a process that uses crushing, screening and other equipment to directly process sand and gravel. It does not need to be washed with water. It is widely used in the production of machine-made sand and has significant advantages.

Click to consult to understand the construction plan of the sand production line

1. Environmental protection and water saving

The dry sand making process does not require water washing, which effectively avoids a series of problems such as sewage discharge and sludge treatment generated in the wet sand making process. Because of this, it has significant advantages in dealing with water scarcity, especially suitable for arid areas or areas with relatively scarce water resources, and has great application value.

2. Good quality of finished sand

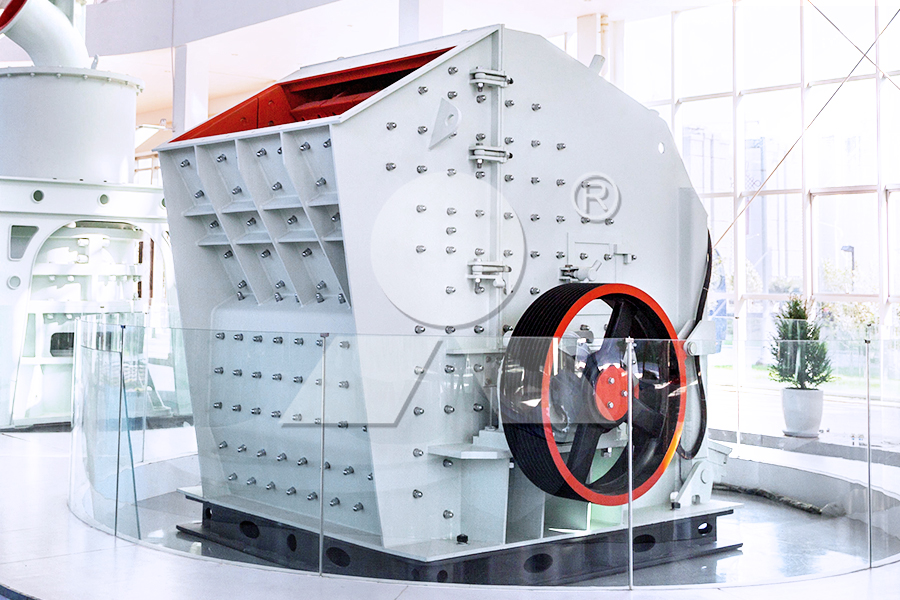

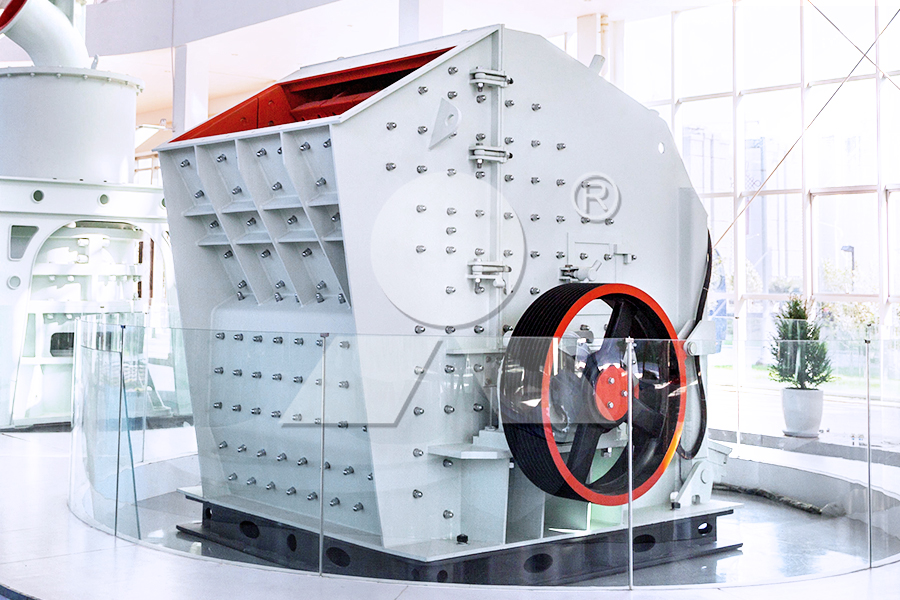

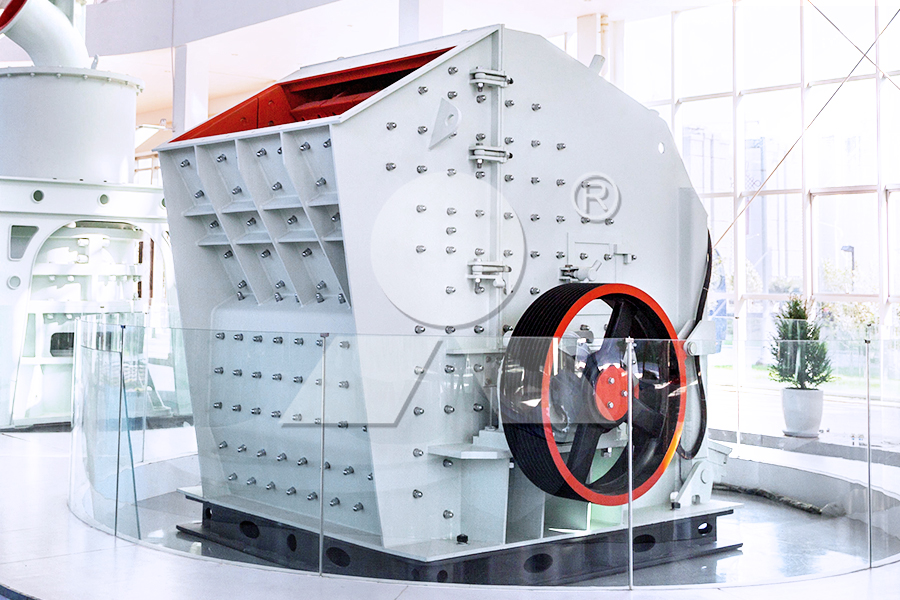

Using equipment such as vertical shaft impact crusher for sand making, the finished sand produced is of excellent quality, round and full grain shape, scientific and reasonable gradation, and low moisture content, usually not more than 2%. This allows it to be directly transported or put into use without special treatment, and it will not freeze even if the temperature is below zero in winter, and can achieve uninterrupted production throughout the year.

3. Stone powder can be recycled

By flexibly adjusting the air volume and air pressure of the powder selector, the stone powder content in the finished sand can be accurately controlled to increase the sand production rate. The stone powder can also be recycled during production. These recycled stone powders have a wide range of uses and can be used as raw materials for roadbed cushions, blocks and cement unburned bricks, effectively increasing product added value and realizing full utilization of resources.

4. Lower production costs

Since water is basically not used in the production process, drainage and sewage treatment equipment are reduced, the system is relatively simple, occupies a small area, requires less investment, and has lower later operating costs.

Previous: SMP Crusher

Next: SMP Crusher

The dry sand making process does not require water washing, is environmentally friendly and water-saving, and the finished sand has excellent quality, full grain shape, reasonable gradation, and recyclable stone powder. The production cost is lower, wh

The dry sand making process does not require water washing, is environmentally friendly and water-saving, and the finished sand has excellent quality, full grain shape, reasonable gradation, and recyclable stone powder. The production cost is lower, which is especially suitable for arid areas.

Dry sand making is a process that uses crushing, screening and other equipment to directly process sand and gravel. It does not need to be washed with water. It is widely used in the production of machine-made sand and has significant advantages.

Click to consult to understand the construction plan of the sand production line

1. Environmental protection and water saving

The dry sand making process does not require water washing, which effectively avoids a series of problems such as sewage discharge and sludge treatment generated in the wet sand making process. Because of this, it has significant advantages in dealing with water scarcity, especially suitable for arid areas or areas with relatively scarce water resources, and has great application value.

2. Good quality of finished sand

Using equipment such as vertical shaft impact crusher for sand making, the finished sand produced is of excellent quality, round and full grain shape, scientific and reasonable gradation, and low moisture content, usually not more than 2%. This allows it to be directly transported or put into use without special treatment, and it will not freeze even if the temperature is below zero in winter, and can achieve uninterrupted production throughout the year.

3. Stone powder can be recycled

By flexibly adjusting the air volume and air pressure of the powder selector, the stone powder content in the finished sand can be accurately controlled to increase the sand production rate. The stone powder can also be recycled during production. These recycled stone powders have a wide range of uses and can be used as raw materials for roadbed cushions, blocks and cement unburned bricks, effectively increasing product added value and realizing full utilization of resources.

4. Lower production costs

Since water is basically not used in the production process, drainage and sewage treatment equipment are reduced, the system is relatively simple, occupies a small area, requires less investment, and has lower later operating costs.

Previous: SMP Crusher

Next: SMP Crusher

Classification, differences and characteristics of hard rocks and soft rocks

Classification, differences and characteristics of hard rocks and soft rocks Zhejiang Yuyao 800 tons per hour tuff sand and gravel production line project: intelligent and green design

Zhejiang Yuyao 800 tons per hour tuff sand and gravel production line project: intelligent and green design Guangxi 1,000 t/h limestone aggregate production line: a model of green mine construction

Guangxi 1,000 t/h limestone aggregate production line: a model of green mine construction How to configure a 2000-ton-per-day construction waste crushing production line

How to configure a 2000-ton-per-day construction waste crushing production line What equipment should be selected to produce high-quality machine-made sand

What equipment should be selected to produce high-quality machine-made sand Classification, differences and characteristics of hard rocks and soft rocks

Classification, differences and characteristics of hard rocks and soft rocks Zhejiang Yuyao 800 tons per hour tuff sand and gravel production line project: intelligent and green design

Zhejiang Yuyao 800 tons per hour tuff sand and gravel production line project: intelligent and green design Guangxi 1,000 t/h limestone aggregate production line: a model of green mine construction

Guangxi 1,000 t/h limestone aggregate production line: a model of green mine construction How to configure a 2000-ton-per-day construction waste crushing production line

How to configure a 2000-ton-per-day construction waste crushing production line What equipment should be selected to produce high-quality machine-made sand

What equipment should be selected to produce high-quality machine-made sand