The gravel aggregate production line of Shandong Binzhou concrete mixing station is equipped with advanced configuration and high efficiency and energy saving. It adopts jaw crusher and 5X sand making machine, the circular vibrating screen has accurate

The gravel aggregate production line of Shandong Binzhou concrete mixing station is equipped with advanced configuration and high efficiency and energy saving. It adopts jaw crusher and 5X sand making machine, the circular vibrating screen has accurate screening, compact structure and smooth operation, becoming an industry model and promoting the sustainable development of the construction industry.

In the modern construction industry, the efficient production of gravel aggregates is crucial to improving the quality of concrete. The gravel aggregate production project of the concrete mixing station in Binzhou, Shandong, has become a model in the industry with its excellent production line configuration.

More gravel aggregate equipment for concrete mixing station

Project Overview

Project Address: Binzhou, Shandong

Processing Materials: Limestone

Output: 2000T/H

Production Line Configuration

The production line configuration of this project is very advanced, and the following equipment is used:

Vibrating feeder: ensure that the material enters the crushing system evenly.

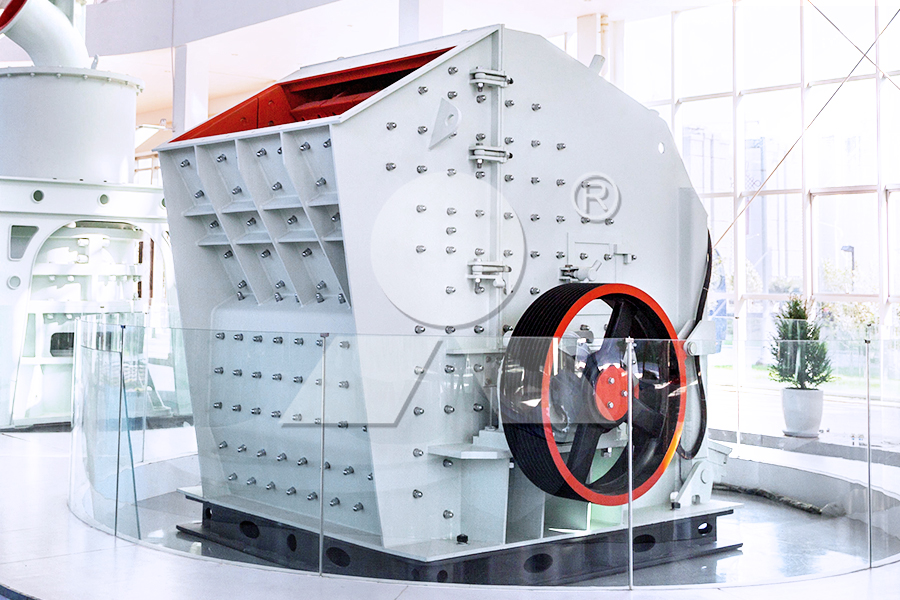

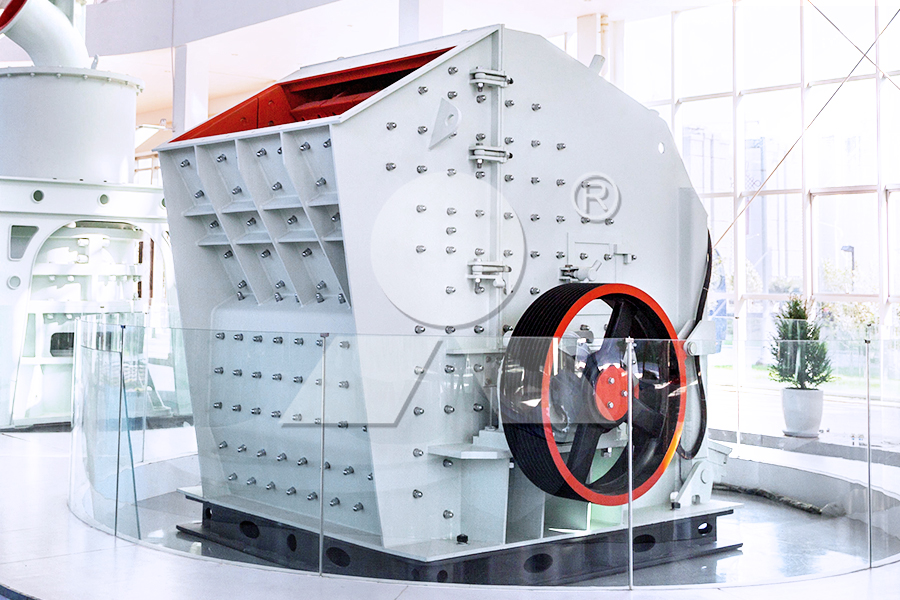

Jaw crusher: perform primary crushing and handle large stones.

5 5X sand making machines: efficient shaping, producing gravel aggregates with excellent particle shape.

9 circular vibrating screens: precise screening to meet the different specifications of customers.

Belt conveyor: realize material transportation between various links and improve production efficiency.

Project advantages

The design concept of this project fully reflects the principle of "high efficiency and energy saving". Through the classic combination of jaw crusher and 5X sand making machine, the material is cyclically crushed and shaped, which greatly improves the production efficiency of sand and gravel aggregates. The addition of circular vibrating screen has improved the screening effect and ensured that the produced sand and gravel aggregates meet the strict requirements of customers.

In addition, the entire production line has a compact structure and smooth operation. The functions of equipment at all levels have been fully utilized, reducing the operating cost, making this production line a typical case.

This sand and gravel aggregate production line in Binzhou, Shandong, has demonstrated the high standards of modern building materials production with its efficient equipment configuration and reasonable design. With the growing demand for sand and gravel aggregates in the industry, such a successful case will undoubtedly provide valuable experience and inspiration for future projects. Choosing an efficient production line will bring more possibilities to the concrete mixing station and promote the sustainable development of the construction industry.

Previous: SMP Crusher

Next: SMP Crusher

The gravel aggregate production line of Shandong Binzhou concrete mixing station is equipped with advanced configuration and high efficiency and energy saving. It adopts jaw crusher and 5X sand making machine, the circular vibrating screen has accurate

The gravel aggregate production line of Shandong Binzhou concrete mixing station is equipped with advanced configuration and high efficiency and energy saving. It adopts jaw crusher and 5X sand making machine, the circular vibrating screen has accurate screening, compact structure and smooth operation, becoming an industry model and promoting the sustainable development of the construction industry.

In the modern construction industry, the efficient production of gravel aggregates is crucial to improving the quality of concrete. The gravel aggregate production project of the concrete mixing station in Binzhou, Shandong, has become a model in the industry with its excellent production line configuration.

More gravel aggregate equipment for concrete mixing station

Project Overview

Project Address: Binzhou, Shandong

Processing Materials: Limestone

Output: 2000T/H

Production Line Configuration

The production line configuration of this project is very advanced, and the following equipment is used:

Vibrating feeder: ensure that the material enters the crushing system evenly.

Jaw crusher: perform primary crushing and handle large stones.

5 5X sand making machines: efficient shaping, producing gravel aggregates with excellent particle shape.

9 circular vibrating screens: precise screening to meet the different specifications of customers.

Belt conveyor: realize material transportation between various links and improve production efficiency.

Project advantages

The design concept of this project fully reflects the principle of "high efficiency and energy saving". Through the classic combination of jaw crusher and 5X sand making machine, the material is cyclically crushed and shaped, which greatly improves the production efficiency of sand and gravel aggregates. The addition of circular vibrating screen has improved the screening effect and ensured that the produced sand and gravel aggregates meet the strict requirements of customers.

In addition, the entire production line has a compact structure and smooth operation. The functions of equipment at all levels have been fully utilized, reducing the operating cost, making this production line a typical case.

This sand and gravel aggregate production line in Binzhou, Shandong, has demonstrated the high standards of modern building materials production with its efficient equipment configuration and reasonable design. With the growing demand for sand and gravel aggregates in the industry, such a successful case will undoubtedly provide valuable experience and inspiration for future projects. Choosing an efficient production line will bring more possibilities to the concrete mixing station and promote the sustainable development of the construction industry.

Previous: SMP Crusher

Next: SMP Crusher

Hydropower dam 900 tons per hour sand and gravel aggregate infrastructure construction project

Hydropower dam 900 tons per hour sand and gravel aggregate infrastructure construction project What are the advantages of mobile iron ore crusher? How much does it cost?

What are the advantages of mobile iron ore crusher? How much does it cost? How is the quality of Shanghai Shibang Crusher and what are its advantages?

How is the quality of Shanghai Shibang Crusher and what are its advantages? Stone crusher manufacturers teach you how to choose a large jaw crusher

Stone crusher manufacturers teach you how to choose a large jaw crusher Fujian 200 tons per hour dry mortar production line case

Fujian 200 tons per hour dry mortar production line case Hydropower dam 900 tons per hour sand and gravel aggregate infrastructure construction project

Hydropower dam 900 tons per hour sand and gravel aggregate infrastructure construction project What are the advantages of mobile iron ore crusher? How much does it cost?

What are the advantages of mobile iron ore crusher? How much does it cost? How is the quality of Shanghai Shibang Crusher and what are its advantages?

How is the quality of Shanghai Shibang Crusher and what are its advantages? Stone crusher manufacturers teach you how to choose a large jaw crusher

Stone crusher manufacturers teach you how to choose a large jaw crusher Fujian 200 tons per hour dry mortar production line case

Fujian 200 tons per hour dry mortar production line case