Recently, the Standardization (Testing and Inspection) Professional Technical Committee of the China Railway Society and the Continuing Education Training Center of the China Academy of Railway Sciences jointly held the first "Training Course on K

Recently, the Standardization (Testing and Inspection) Professional Technical Committee of the China Railway Society and the Continuing Education Training Center of the China Academy of Railway Sciences jointly held the first "Training Course on Key Technologies of Railway Mechanized Aggregates" in Chengdu, Sichuan Province. The course attracted approximately 300 participants from the industry, who learned and exchanged ideas on the application and technology of manufactured sand in railway engineering.

Currently, manufactured sand and gravel aggregates have become the mainstay of construction aggregates in my country, especially in the important engineering construction field of the railway system, where the quality requirements for sand and gravel products are extremely high. With the continuous improvement of the performance of manufactured sand and gravel aggregate products and the depletion of river sand resources, the railway system has actively explored the application practices and established a standard system for manufactured sand, making significant contributions to its application in railway engineering. The successful holding of this "Training Course on Key Technologies of Railway Mechanized Aggregates" will help key personnel in the railway field to deeply understand and effectively apply manufactured sand, which is of great significance for promoting the application of high-quality manufactured sand and ensuring the quality of national railway projects.

At the training session, Hu Youyi, President of the China Sand and Gravel Association, lectured on "The Development and Application of Mechanized Sand and Gravel in Key Projects." He detailed the development history of sand and gravel aggregates and crushing and screening equipment, the progress and achievements of manufactured sand and gravel in recent years, relevant government documents and standards supporting the development of manufactured sand and gravel, and case studies of typical domestic and international sand and gravel aggregate companies.

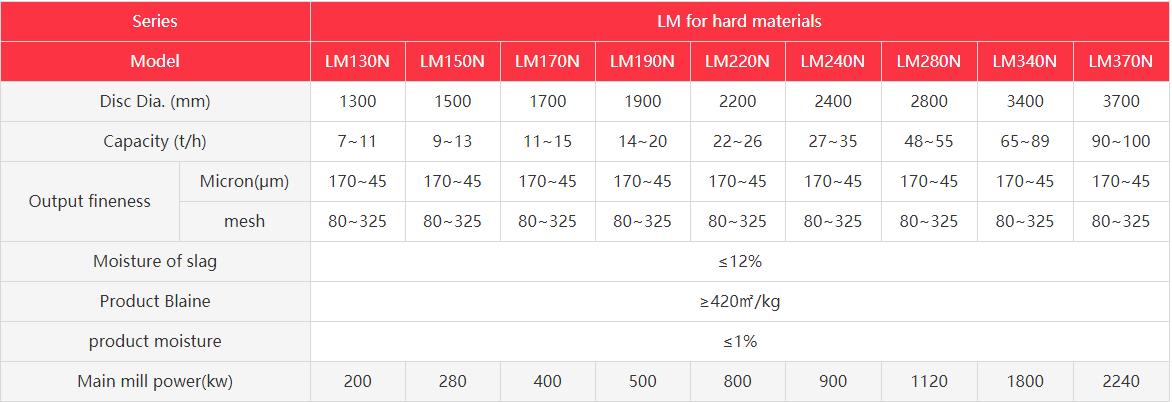

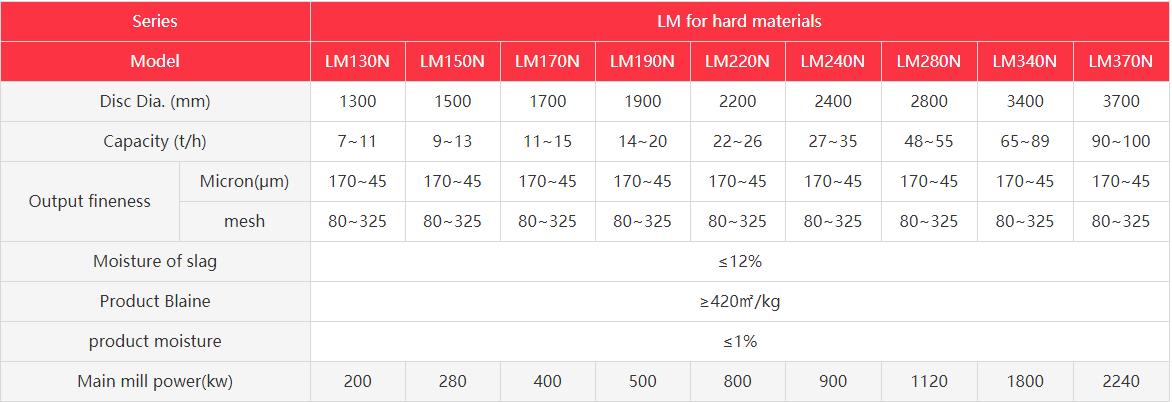

Shibang Group's Contributions and Equipment

Shibang Group has made significant contributions to the research and development and supply of manufactured sand production equipment. The following are some key pieces of equipment:

PEW European Jaw Crusher

Feed Size: 180-930mm

Discharge Range: 10-275mm

Output: 12-650T/H

Product Introduction: The PEW European Jaw Crusher is suitable for crushing ores, rocks, slag, etc., with a compressive strength not exceeding 280Mpa. It is mainly used for medium and fine crushing in metallurgical, mining, chemical, cement, construction, refractory materials, and ceramic industries.

Technical Features:

High-quality manufacturing materials

Finite element analysis technology, resulting in higher strength

Symmetrical "V"-shaped crushing chamber

Toothed guard plates for higher output

Larger bearings for higher load-bearing capacity

PE Jaw Crusher

Feed Size: 125-1200mm

Discharge Range: 20-360mm

Output: 5-1100T/H

Product Introduction: PE jaw crushers are widely used in various industries such as mining, metallurgy, building materials, highways, railways, water conservancy, and chemicals. It is one of the flagship products of Shibang Group, which is at a high level both domestically and internationally, especially in the design and production of large jaw crushers.

Technical Features:

Deep crushing chamber with no dead zone

Large crushing ratio, uniform product particle size, low noise, and minimal dust

Shipper-type discharge port adjustment device

Large discharge port adjustment range, offering high flexibility

Applications in Railway Construction: Shibang Group's manufactured sand production equipment, such as the VSI5X sand making machine, creates construction sand production lines that produce aggregates with excellent particle shape and uniform size. The concrete produced rivals that made from natural sand. Through efficient crushing and screening, the manufactured sand not only meets the high-quality aggregate requirements of railway construction but also significantly improves the quality and service life of railway projects.

In road, bridge, and railway projects, the use of Shibang Group's manufactured sand production equipment not only improves the quality of aggregates but also provides reliable material support for construction. Shibang Group is committed to promoting the widespread application of high-quality manufactured sand in various projects, contributing to the high-quality development of national infrastructure construction.

Shibang Group believes that by providing advanced manufactured sand production equipment and technical support, it can further promote the construction and development of railway systems, improve project quality, and ensure the smooth progress and long-term use of railway construction projects.

Previous: SMP Crusher

Next: SMP Crusher

Recently, the Standardization (Testing and Inspection) Professional Technical Committee of the China Railway Society and the Continuing Education Training Center of the China Academy of Railway Sciences jointly held the first "Training Course on K

Recently, the Standardization (Testing and Inspection) Professional Technical Committee of the China Railway Society and the Continuing Education Training Center of the China Academy of Railway Sciences jointly held the first "Training Course on Key Technologies of Railway Mechanized Aggregates" in Chengdu, Sichuan Province. The course attracted approximately 300 participants from the industry, who learned and exchanged ideas on the application and technology of manufactured sand in railway engineering.

Currently, manufactured sand and gravel aggregates have become the mainstay of construction aggregates in my country, especially in the important engineering construction field of the railway system, where the quality requirements for sand and gravel products are extremely high. With the continuous improvement of the performance of manufactured sand and gravel aggregate products and the depletion of river sand resources, the railway system has actively explored the application practices and established a standard system for manufactured sand, making significant contributions to its application in railway engineering. The successful holding of this "Training Course on Key Technologies of Railway Mechanized Aggregates" will help key personnel in the railway field to deeply understand and effectively apply manufactured sand, which is of great significance for promoting the application of high-quality manufactured sand and ensuring the quality of national railway projects.

At the training session, Hu Youyi, President of the China Sand and Gravel Association, lectured on "The Development and Application of Mechanized Sand and Gravel in Key Projects." He detailed the development history of sand and gravel aggregates and crushing and screening equipment, the progress and achievements of manufactured sand and gravel in recent years, relevant government documents and standards supporting the development of manufactured sand and gravel, and case studies of typical domestic and international sand and gravel aggregate companies.

Shibang Group's Contributions and Equipment

Shibang Group has made significant contributions to the research and development and supply of manufactured sand production equipment. The following are some key pieces of equipment:

PEW European Jaw Crusher

Feed Size: 180-930mm

Discharge Range: 10-275mm

Output: 12-650T/H

Product Introduction: The PEW European Jaw Crusher is suitable for crushing ores, rocks, slag, etc., with a compressive strength not exceeding 280Mpa. It is mainly used for medium and fine crushing in metallurgical, mining, chemical, cement, construction, refractory materials, and ceramic industries.

Technical Features:

High-quality manufacturing materials

Finite element analysis technology, resulting in higher strength

Symmetrical "V"-shaped crushing chamber

Toothed guard plates for higher output

Larger bearings for higher load-bearing capacity

PE Jaw Crusher

Feed Size: 125-1200mm

Discharge Range: 20-360mm

Output: 5-1100T/H

Product Introduction: PE jaw crushers are widely used in various industries such as mining, metallurgy, building materials, highways, railways, water conservancy, and chemicals. It is one of the flagship products of Shibang Group, which is at a high level both domestically and internationally, especially in the design and production of large jaw crushers.

Technical Features:

Deep crushing chamber with no dead zone

Large crushing ratio, uniform product particle size, low noise, and minimal dust

Shipper-type discharge port adjustment device

Large discharge port adjustment range, offering high flexibility

Applications in Railway Construction: Shibang Group's manufactured sand production equipment, such as the VSI5X sand making machine, creates construction sand production lines that produce aggregates with excellent particle shape and uniform size. The concrete produced rivals that made from natural sand. Through efficient crushing and screening, the manufactured sand not only meets the high-quality aggregate requirements of railway construction but also significantly improves the quality and service life of railway projects.

In road, bridge, and railway projects, the use of Shibang Group's manufactured sand production equipment not only improves the quality of aggregates but also provides reliable material support for construction. Shibang Group is committed to promoting the widespread application of high-quality manufactured sand in various projects, contributing to the high-quality development of national infrastructure construction.

Shibang Group believes that by providing advanced manufactured sand production equipment and technical support, it can further promote the construction and development of railway systems, improve project quality, and ensure the smooth progress and long-term use of railway construction projects.

Previous: SMP Crusher

Next: SMP Crusher

Gansu Public Transport Construction Group selects Shibang Equipment for its 500-ton-per-hour basalt crushing and sand making project.

Gansu Public Transport Construction Group selects Shibang Equipment for its 500-ton-per-hour basalt crushing and sand making project. Price of large stone crushing equipment

Price of large stone crushing equipment How much does a stone crusher cost, and what models are available?

How much does a stone crusher cost, and what models are available? Gansu Public Transport Construction Groups 500-ton-per-hour limestone crushing and sand making project collaborates with Shibang.

Gansu Public Transport Construction Groups 500-ton-per-hour limestone crushing and sand making project collaborates with Shibang. Shibang Equipment was selected for a basalt crushing and sand making project with a capacity of 500 tons per hour.

Shibang Equipment was selected for a basalt crushing and sand making project with a capacity of 500 tons per hour. Gansu Public Transport Construction Group selects Shibang Equipment for its 500-ton-per-hour basalt crushing and sand making project.

Gansu Public Transport Construction Group selects Shibang Equipment for its 500-ton-per-hour basalt crushing and sand making project. Price of large stone crushing equipment

Price of large stone crushing equipment How much does a stone crusher cost, and what models are available?

How much does a stone crusher cost, and what models are available? Gansu Public Transport Construction Groups 500-ton-per-hour limestone crushing and sand making project collaborates with Shibang.

Gansu Public Transport Construction Groups 500-ton-per-hour limestone crushing and sand making project collaborates with Shibang. Shibang Equipment was selected for a basalt crushing and sand making project with a capacity of 500 tons per hour.

Shibang Equipment was selected for a basalt crushing and sand making project with a capacity of 500 tons per hour.