Silica sand stone is a hard, wear-resistant, chemically stable silicate minerals, its main mineral composition is SiO2 , silica sand colour is milky white or colourless translucent, hardness 7, brittle and non-dissolving, shell-like fracture, greasy lu

Silica sand stone is a hard, wear-resistant, chemically stable silicate minerals, its main mineral composition is SiO2 , silica sand colour is milky white or colourless translucent, hardness 7, brittle and non-dissolving, shell-like fracture, greasy luster, relative density of 2.65, its chemical, thermal and mechanical properties have obvious anisotropy, insoluble in acid, slightly soluble in KOH solution, melting point 1750 ℃. The colour is milky white, light yellow, brown and grey, silica sand has high refractory properties.

Silica sand stone is an important industrial mineral raw material, widely used in glass, casting, ceramics and refractories, metallurgy, construction, chemical industry, plastics, rubber, abrasives and other industries.

It is used in ceramics and refractory materials; glass; metallurgy; construction; machinery; electronics; rubber, plastics; coatings; aviation, aerospace; as well as road building materials, artificial marble, cement physical properties test materials (i.e. cement standard sand), etc. .

Silica sandstone crushing process

Silica sand stone material passes through the silo, fed evenly by the vibrating feeder, and conveyed to the jaw crusher for primary crushing, after primary crushing, the silica sand stone and the fine silica sand stone screened by the vibrating feeder are conveyed together by the belt conveyor to the cone crusher for medium and fine crushing, and after crushing, it is screened by the circular vibrating screen. The larger particles of silica sandstone are sent back to the cone crusher for crushing again; the medium size silica sandstone is sent to the sand making machine for fine crushing and shaping; the qualified materials are washed by the sand washing machine as the final products.

Medium granularity silica sandstone is sent to sand making machine for fine crushing, screened by circular vibrating screen, larger granularity silica sandstone is sent back to sand making machine for crushing again, qualified products are sent by belt conveyor to storage heap for storage, fine silica sandstone is sent to sand washing machine for cleaning. That is the finished product.

Related equipment

Vibrating Feeder

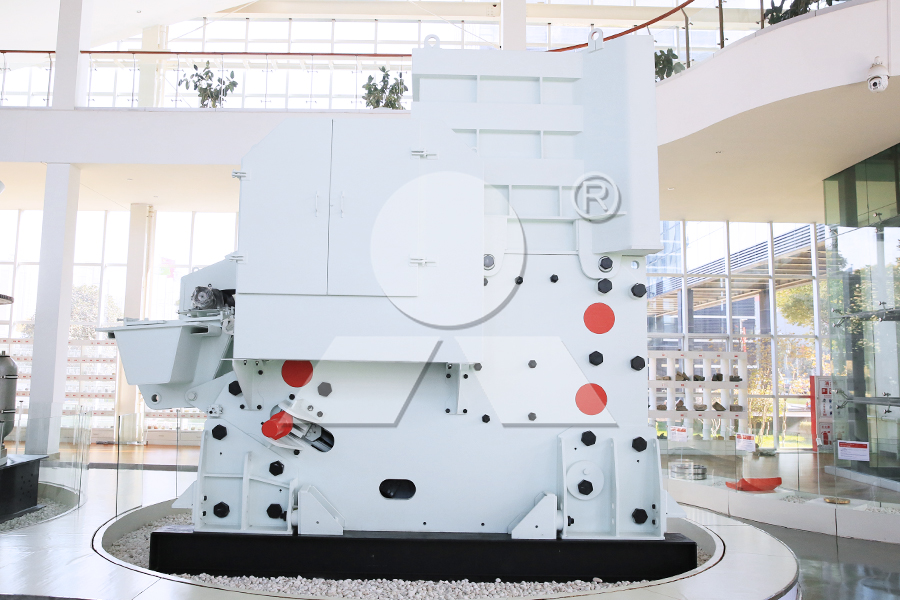

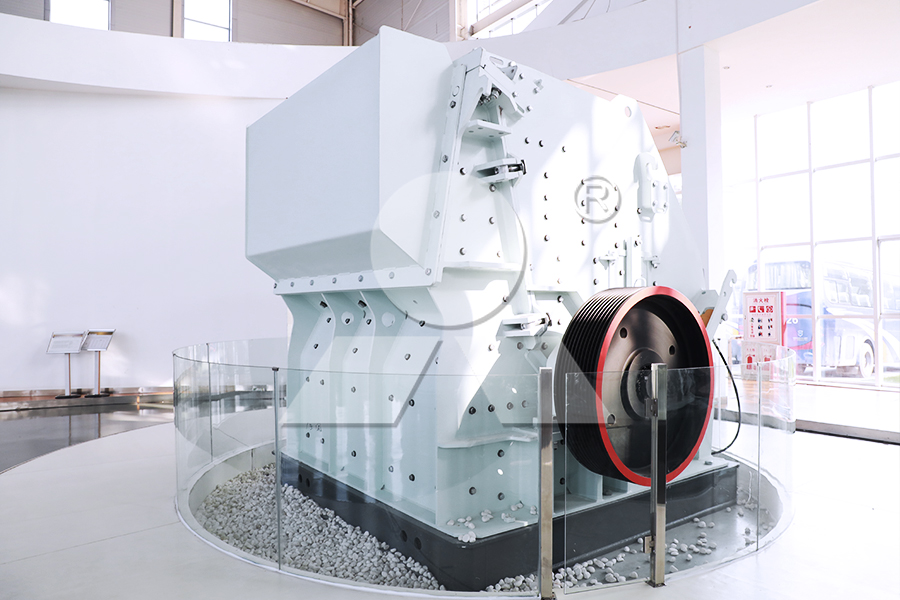

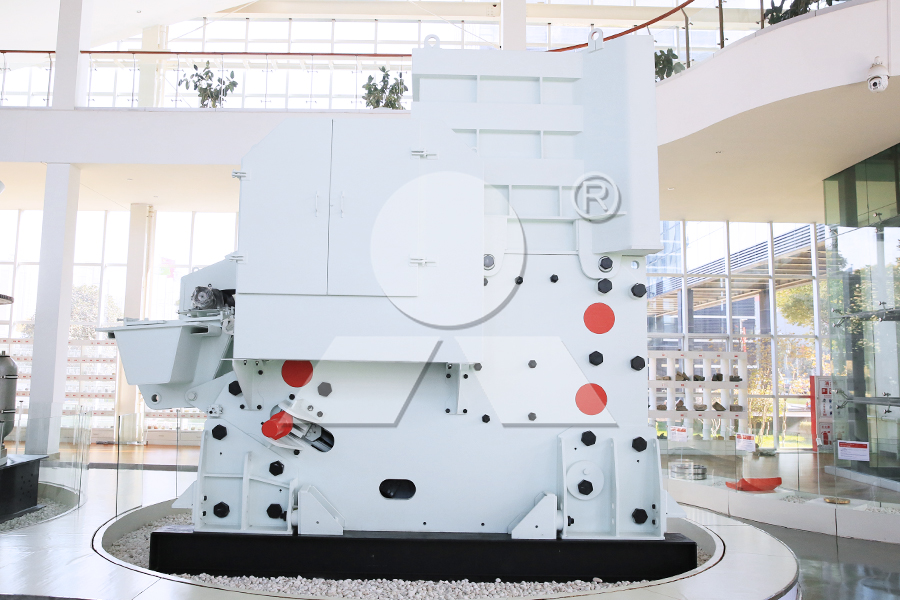

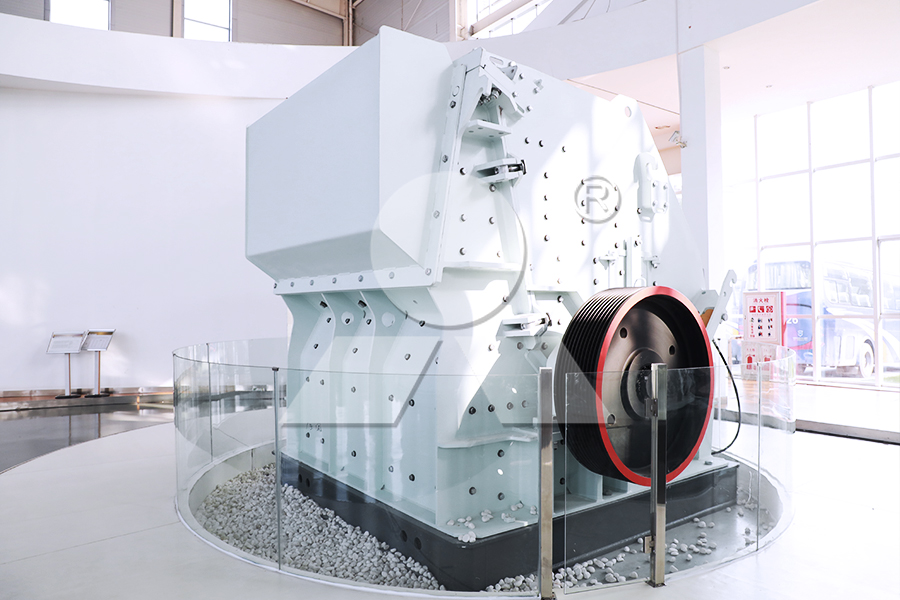

Jaw Crusher

Cone Crusher

Circular Vibrating Screen

Sand Making Machine

Previous: SMP Crusher

Next: SMP Crusher

Silica sand stone is a hard, wear-resistant, chemically stable silicate minerals, its main mineral composition is SiO2 , silica sand colour is milky white or colourless translucent, hardness 7, brittle and non-dissolving, shell-like fracture, greasy lu

Silica sand stone is a hard, wear-resistant, chemically stable silicate minerals, its main mineral composition is SiO2 , silica sand colour is milky white or colourless translucent, hardness 7, brittle and non-dissolving, shell-like fracture, greasy luster, relative density of 2.65, its chemical, thermal and mechanical properties have obvious anisotropy, insoluble in acid, slightly soluble in KOH solution, melting point 1750 ℃. The colour is milky white, light yellow, brown and grey, silica sand has high refractory properties.

Silica sand stone is an important industrial mineral raw material, widely used in glass, casting, ceramics and refractories, metallurgy, construction, chemical industry, plastics, rubber, abrasives and other industries.

It is used in ceramics and refractory materials; glass; metallurgy; construction; machinery; electronics; rubber, plastics; coatings; aviation, aerospace; as well as road building materials, artificial marble, cement physical properties test materials (i.e. cement standard sand), etc. .

Silica sandstone crushing process

Silica sand stone material passes through the silo, fed evenly by the vibrating feeder, and conveyed to the jaw crusher for primary crushing, after primary crushing, the silica sand stone and the fine silica sand stone screened by the vibrating feeder are conveyed together by the belt conveyor to the cone crusher for medium and fine crushing, and after crushing, it is screened by the circular vibrating screen. The larger particles of silica sandstone are sent back to the cone crusher for crushing again; the medium size silica sandstone is sent to the sand making machine for fine crushing and shaping; the qualified materials are washed by the sand washing machine as the final products.

Medium granularity silica sandstone is sent to sand making machine for fine crushing, screened by circular vibrating screen, larger granularity silica sandstone is sent back to sand making machine for crushing again, qualified products are sent by belt conveyor to storage heap for storage, fine silica sandstone is sent to sand washing machine for cleaning. That is the finished product.

Related equipment

Vibrating Feeder

Jaw Crusher

Cone Crusher

Circular Vibrating Screen

Sand Making Machine

Previous: SMP Crusher

Next: SMP Crusher