There is a saying in the milling industry called "three points of the process, seven points of the operation", which directly points out the importance of operating techniques and methods of milling production. For many users, how to co

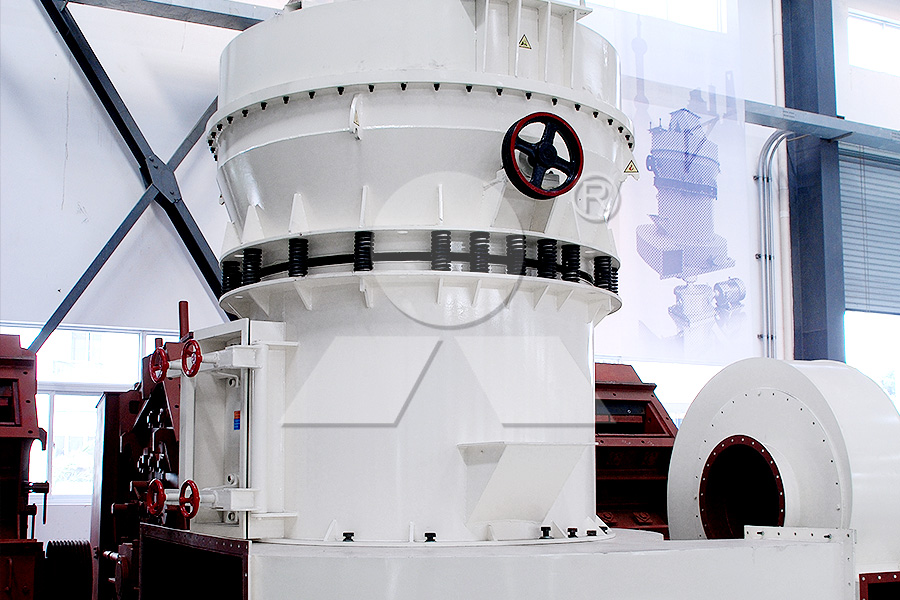

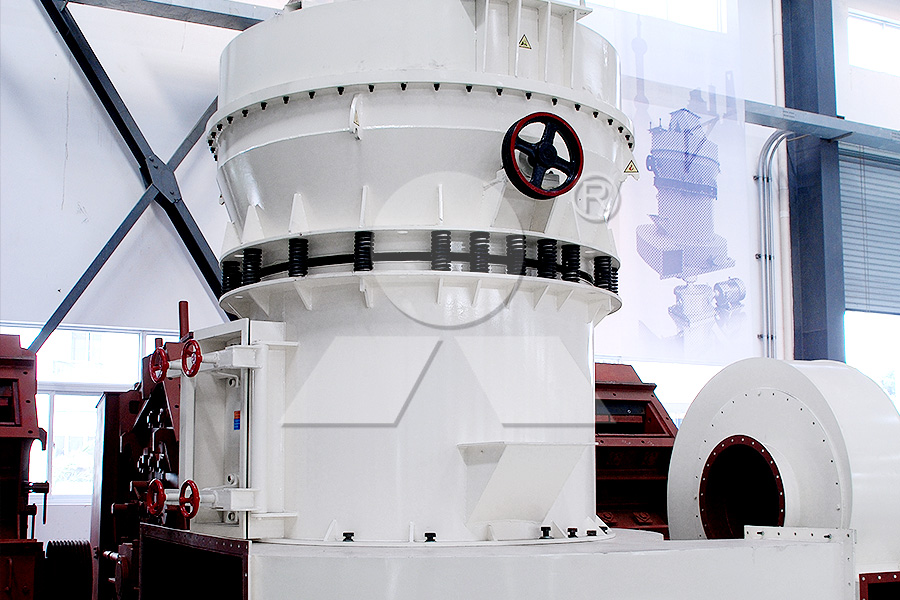

There is a saying in the milling industry called "three points of the process, seven points of the operation", which directly points out the importance of operating techniques and methods of milling production. For many users, how to correctly use the newly purchased processing limestone mill is a very important issue, it is not only about the improvement of production efficiency, but also closely related to the personal safety of the operator. This article will introduce the correct use of processing limestone mill.

1, precautions before starting

Processing limestone mill before starting, you need to check whether all the access doors are tightly closed, with a jaw crusher and elevator milling production line, to check whether the crusher's liner gap is in line with the size of the feed size, adjust the speed of the analysing machine should be up to approximate the finished product size requirements, adjust the fan to maintain the appropriate air volume.

2、Opening sequence

(1) Firstly, switch on the bucket elevator to achieve continuous and even material conveying;

(2) Secondly, wait until there are materials in the material warehouse, open the analyser;

(3) Again, start the blower when no load, wait until normal operation and then load the material;

(4) Then, start the main machine of the limestone mill, and start the electromagnetic vibrating feeder at the moment of starting the main machine. At this point, the processing limestone mill starts to work normally.

3、Precautions in operation

(1) processing limestone mill in normal operation is not allowed to refuel, to ensure production safety;

(2) processing limestone mill in part of the occurrence of abnormal noise, or sudden increase in load, should be immediately shut down to check, troubleshooting, in order to avoid major accidents;

(3) When you start the machine again, you need to take out all the residual material in the machine, otherwise the current will be too large when you start the machine, affecting the start-up, and in serious cases, it will even burn down the equipment.

4、Shutdown sequence

(1) Shut down the feeder first to stop feeding;

(2) Stop the main machine after the feeder stops for about one minute;

(3) Stop the blower after the residual material is cleaned up;

(4) The correct stopping sequence is: feeder - host - blower - analyser;

(5) It should be noted that when the elevator conveys materials to the bin after a certain amount, first stop the crusher and then stop the elevator, the amount of material storage as needed.

SMPCRUSHER is a high-tech company integrating R&D, production and distribution, and provides crusher, sand making, grinding equipment, mobile crushing station, etc. mature products and solutions used in aggregate, mining and waste recycling. At present, we have established cooperative relations with customers in more than 170 countries, and helped them plan reasonable programme and realize scientific process.

Previous: SMP Crusher

Next: SMP Crusher

There is a saying in the milling industry called "three points of the process, seven points of the operation", which directly points out the importance of operating techniques and methods of milling production. For many users, how to co

There is a saying in the milling industry called "three points of the process, seven points of the operation", which directly points out the importance of operating techniques and methods of milling production. For many users, how to correctly use the newly purchased processing limestone mill is a very important issue, it is not only about the improvement of production efficiency, but also closely related to the personal safety of the operator. This article will introduce the correct use of processing limestone mill.

1, precautions before starting

Processing limestone mill before starting, you need to check whether all the access doors are tightly closed, with a jaw crusher and elevator milling production line, to check whether the crusher's liner gap is in line with the size of the feed size, adjust the speed of the analysing machine should be up to approximate the finished product size requirements, adjust the fan to maintain the appropriate air volume.

2、Opening sequence

(1) Firstly, switch on the bucket elevator to achieve continuous and even material conveying;

(2) Secondly, wait until there are materials in the material warehouse, open the analyser;

(3) Again, start the blower when no load, wait until normal operation and then load the material;

(4) Then, start the main machine of the limestone mill, and start the electromagnetic vibrating feeder at the moment of starting the main machine. At this point, the processing limestone mill starts to work normally.

3、Precautions in operation

(1) processing limestone mill in normal operation is not allowed to refuel, to ensure production safety;

(2) processing limestone mill in part of the occurrence of abnormal noise, or sudden increase in load, should be immediately shut down to check, troubleshooting, in order to avoid major accidents;

(3) When you start the machine again, you need to take out all the residual material in the machine, otherwise the current will be too large when you start the machine, affecting the start-up, and in serious cases, it will even burn down the equipment.

4、Shutdown sequence

(1) Shut down the feeder first to stop feeding;

(2) Stop the main machine after the feeder stops for about one minute;

(3) Stop the blower after the residual material is cleaned up;

(4) The correct stopping sequence is: feeder - host - blower - analyser;

(5) It should be noted that when the elevator conveys materials to the bin after a certain amount, first stop the crusher and then stop the elevator, the amount of material storage as needed.

SMPCRUSHER is a high-tech company integrating R&D, production and distribution, and provides crusher, sand making, grinding equipment, mobile crushing station, etc. mature products and solutions used in aggregate, mining and waste recycling. At present, we have established cooperative relations with customers in more than 170 countries, and helped them plan reasonable programme and realize scientific process.

Previous: SMP Crusher

Next: SMP Crusher