In the field of sand and gravel aggregate production, high material hardness and uneven particle size are headaches for many companies. Traditional crushing equipment often has low efficiency, high energy consumption, and easy wear when processing such

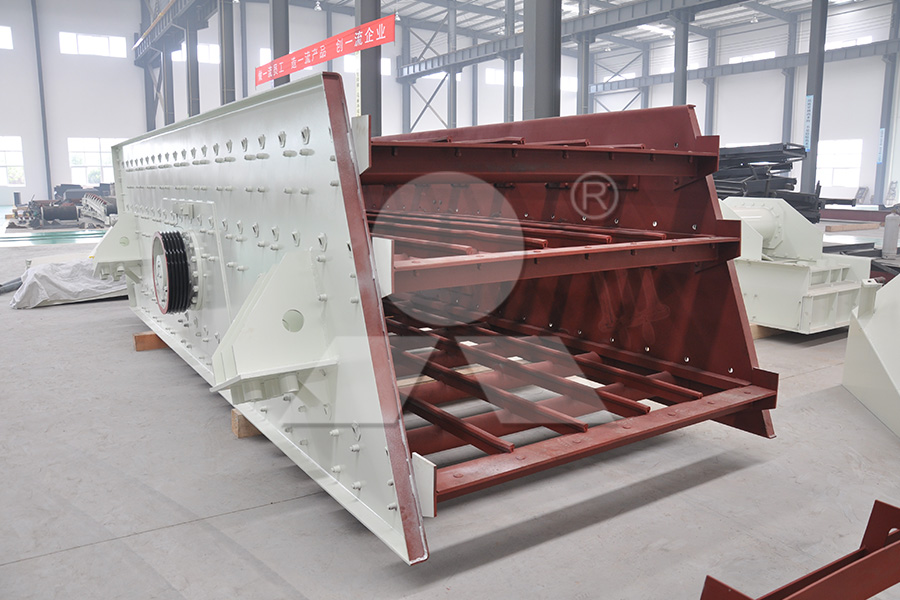

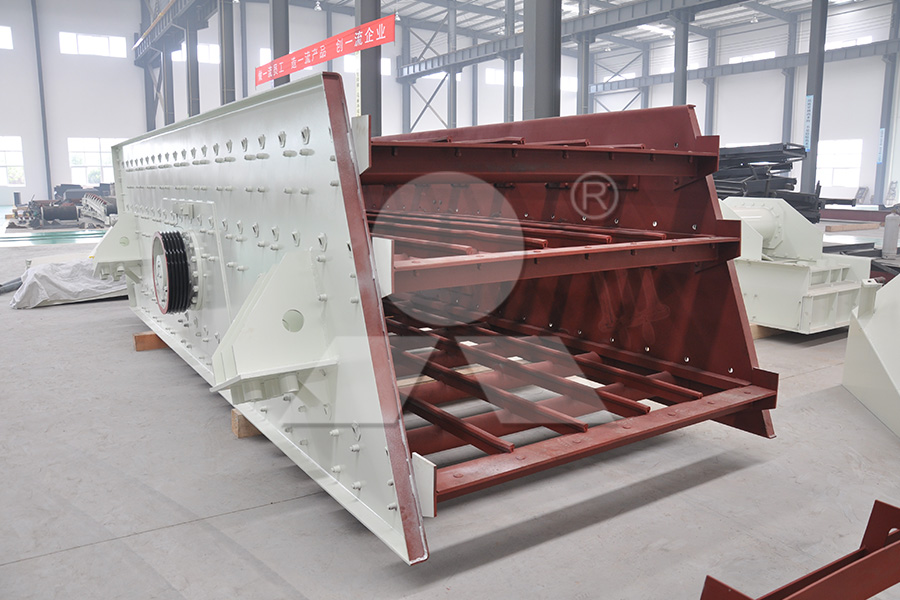

In the field of sand and gravel aggregate production, high material hardness and uneven particle size are headaches for many companies. Traditional crushing equipment often has low efficiency, high energy consumption, and easy wear when processing such materials, which makes it difficult to meet the rhythm of modern large-scale production. With more than 40 years of technological accumulation, Chang Liming Machinery has launched the Liming double-roll crusher, with high efficiency, energy saving, intelligent environmental protection as its core advantages, to provide a new solution for the green transformation of the industry.

1. Product highlights: Innovative technology enables efficient production

1. Structural optimization, excellent performance

The new generation of double-roll crushers adopts the principle of double-roller extrusion crushing, and flexibly adjusts the discharge particle size (2-10mm) through hydraulic or spring devices. The finished product has a needle-like content of less than 5%, and the particle shape is uniform, meeting the needs of high-standard sand and gravel aggregates. The roller surface is made of high-chromium alloy, which increases wear resistance by 50%, and the service life can reach more than 3 times that of ordinary materials, greatly reducing maintenance costs.

2. Energy saving and environmental protection, cost reduction and efficiency improvement

The equipment is equipped with a dual-motor drive system, with a power consumption of as low as 1.6 degrees per ton, which saves 30% energy compared with traditional equipment. The fully sealed structure combined with pulse dust removal technology has dust emission less than 30mg/m³ and noise control ≤75dB, which meets national environmental protection standards and helps enterprises pass environmental impact assessment.

3. Intelligent control, convenient and labor-saving

The modular design simplifies the disassembly and assembly process, and it only takes 1-2 hours to replace wear parts, minimizing downtime losses.

2. Application scenarios: multi-industry coverage, helping resource recycling

The equipment can handle materials with compressive strength ≤160MPa, including river pebbles, granite, coal gangue, construction waste, etc., and is widely used in:

Mining field: fine crushing pretreatment of metal ores to improve mineral processing efficiency;

Building materials production: crushing of limestone and gypsum to prepare high-quality cement and concrete;

Environmental recycling: crushing of construction waste into recycled aggregates, with a resource utilization rate of more than 90%.

After a customer in Shanxi introduced the Liming double-roll crusher, the coal crushing capacity increased to 100t/h, the power consumption decreased by 25%, and the annual cost savings exceeded 500,000 yuan.

3. Service Commitment: Build Trust with Quality and Create Value with Service

As a leading enterprise in China's mining machinery, Liming Machinery has always taken "Building Liming Brand and Satisfying Users" as its core concept. The company has four intelligent production bases, passed ISO9001 international quality certification, and its products are sold to more than 160 countries around the world. We promise:

24-hour response: The technical team will guide the installation and commissioning throughout the process and provide lifelong maintenance support;

Customized solutions: Design process flow according to customer needs and match the optimal equipment combination;

Cost control: Provide free plant planning and energy consumption optimization suggestions to help customers reduce costs and increase efficiency.

4. Looking to the future: Promote the intelligent upgrading of the industry

Liming Machinery will continue to deepen technological innovation and promote the sand and gravel aggregate industry to move towards intelligence, greenness and efficiency. Create greater value for global customers.

Previous: SMP Crusher

Next: SMP Crusher

In the field of sand and gravel aggregate production, high material hardness and uneven particle size are headaches for many companies. Traditional crushing equipment often has low efficiency, high energy consumption, and easy wear when processing such

In the field of sand and gravel aggregate production, high material hardness and uneven particle size are headaches for many companies. Traditional crushing equipment often has low efficiency, high energy consumption, and easy wear when processing such materials, which makes it difficult to meet the rhythm of modern large-scale production. With more than 40 years of technological accumulation, Chang Liming Machinery has launched the Liming double-roll crusher, with high efficiency, energy saving, intelligent environmental protection as its core advantages, to provide a new solution for the green transformation of the industry.

1. Product highlights: Innovative technology enables efficient production

1. Structural optimization, excellent performance

The new generation of double-roll crushers adopts the principle of double-roller extrusion crushing, and flexibly adjusts the discharge particle size (2-10mm) through hydraulic or spring devices. The finished product has a needle-like content of less than 5%, and the particle shape is uniform, meeting the needs of high-standard sand and gravel aggregates. The roller surface is made of high-chromium alloy, which increases wear resistance by 50%, and the service life can reach more than 3 times that of ordinary materials, greatly reducing maintenance costs.

2. Energy saving and environmental protection, cost reduction and efficiency improvement

The equipment is equipped with a dual-motor drive system, with a power consumption of as low as 1.6 degrees per ton, which saves 30% energy compared with traditional equipment. The fully sealed structure combined with pulse dust removal technology has dust emission less than 30mg/m³ and noise control ≤75dB, which meets national environmental protection standards and helps enterprises pass environmental impact assessment.

3. Intelligent control, convenient and labor-saving

The modular design simplifies the disassembly and assembly process, and it only takes 1-2 hours to replace wear parts, minimizing downtime losses.

2. Application scenarios: multi-industry coverage, helping resource recycling

The equipment can handle materials with compressive strength ≤160MPa, including river pebbles, granite, coal gangue, construction waste, etc., and is widely used in:

Mining field: fine crushing pretreatment of metal ores to improve mineral processing efficiency;

Building materials production: crushing of limestone and gypsum to prepare high-quality cement and concrete;

Environmental recycling: crushing of construction waste into recycled aggregates, with a resource utilization rate of more than 90%.

After a customer in Shanxi introduced the Liming double-roll crusher, the coal crushing capacity increased to 100t/h, the power consumption decreased by 25%, and the annual cost savings exceeded 500,000 yuan.

3. Service Commitment: Build Trust with Quality and Create Value with Service

As a leading enterprise in China's mining machinery, Liming Machinery has always taken "Building Liming Brand and Satisfying Users" as its core concept. The company has four intelligent production bases, passed ISO9001 international quality certification, and its products are sold to more than 160 countries around the world. We promise:

24-hour response: The technical team will guide the installation and commissioning throughout the process and provide lifelong maintenance support;

Customized solutions: Design process flow according to customer needs and match the optimal equipment combination;

Cost control: Provide free plant planning and energy consumption optimization suggestions to help customers reduce costs and increase efficiency.

4. Looking to the future: Promote the intelligent upgrading of the industry

Liming Machinery will continue to deepen technological innovation and promote the sand and gravel aggregate industry to move towards intelligence, greenness and efficiency. Create greater value for global customers.

Previous: SMP Crusher

Next: SMP Crusher

Liming crawler mobile crushing and screening station helps coal mines to produce efficiently and greenly

Liming crawler mobile crushing and screening station helps coal mines to produce efficiently and greenly Liming crawler mobile crushing and screening station, a mobile crushing and sand making plant! No infrastructure required, lower investment cost

Liming crawler mobile crushing and screening station, a mobile crushing and sand making plant! No infrastructure required, lower investment cost The development prospects of the construction and decoration waste treatment industry are still broad! Liming Construction and Decoration Waste Intelligent Regeneration System provides you with a one-stop complete solution

The development prospects of the construction and decoration waste treatment industry are still broad! Liming Construction and Decoration Waste Intelligent Regeneration System provides you with a one-stop complete solution The artificial sand industry has arrived: the market prospects are infinite, and Liming Machinery leads the future

The artificial sand industry has arrived: the market prospects are infinite, and Liming Machinery leads the future How many types of shale crushers are there? How to choose

How many types of shale crushers are there? How to choose Liming crawler mobile crushing and screening station helps coal mines to produce efficiently and greenly

Liming crawler mobile crushing and screening station helps coal mines to produce efficiently and greenly Liming crawler mobile crushing and screening station, a mobile crushing and sand making plant! No infrastructure required, lower investment cost

Liming crawler mobile crushing and screening station, a mobile crushing and sand making plant! No infrastructure required, lower investment cost The development prospects of the construction and decoration waste treatment industry are still broad! Liming Construction and Decoration Waste Intelligent Regeneration System provides you with a one-stop complete solution

The development prospects of the construction and decoration waste treatment industry are still broad! Liming Construction and Decoration Waste Intelligent Regeneration System provides you with a one-stop complete solution The artificial sand industry has arrived: the market prospects are infinite, and Liming Machinery leads the future

The artificial sand industry has arrived: the market prospects are infinite, and Liming Machinery leads the future How many types of shale crushers are there? How to choose

How many types of shale crushers are there? How to choose