The complete set of sand and gravel aggregate production line equipment mainly consists of crushing equipment, sand making equipment and auxiliary equipment. The main equipment is introduced below:1. Jaw crusher (C6X series)

The complete set of sand and gravel aggregate production line equipment mainly consists of crushing equipment, sand making equipment and auxiliary equipment. The main equipment is introduced below:

1. Jaw crusher (C6X series)

Product features: high-efficiency crushing chamber design, optimizing material crushing efficiency; combined frame, stable structure and flexible assembly. Integrated motor integration, strong power and easy maintenance. Foot-free elastic support, shock reduction and noise reduction. Hydraulic adjustment system, precise control of operating parameters. Fully automatic centralized lubrication, extending equipment life, reducing downtime maintenance, and comprehensively improving crushing operation efficiency and stability.

2. Impact crusher (CI5X series)

Product features: high-speed crushing efficiency, heavy-duty rotor with large inertia and high precision; high wear-resistant materials enhance durability, full hydraulic operation is multifunctional and convenient, and the overall performance is excellent.

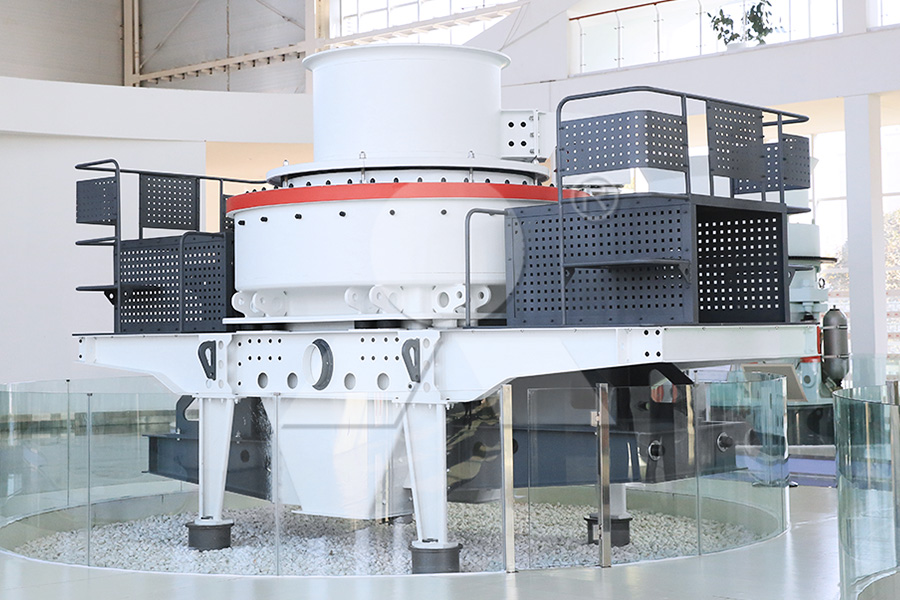

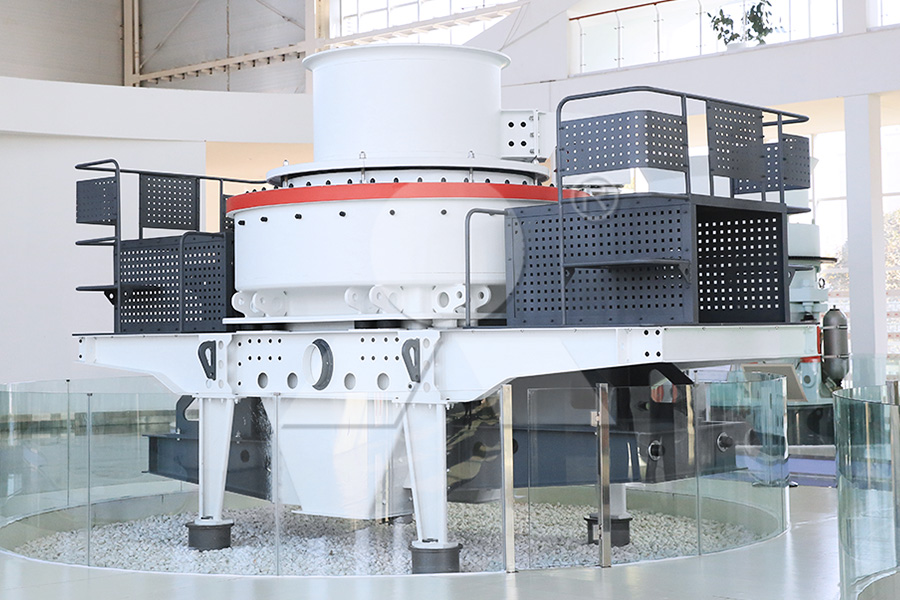

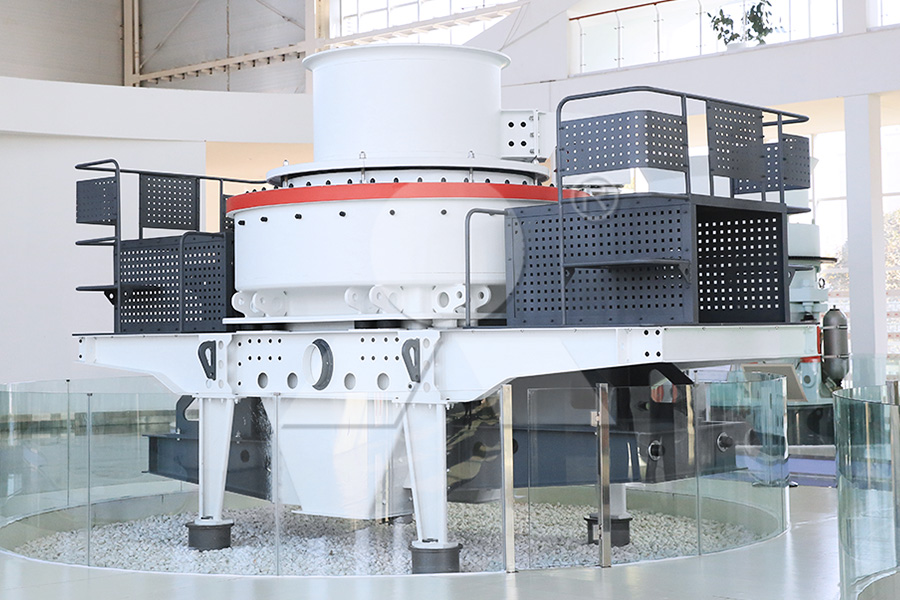

3. Multi-cylinder hydraulic cone crusher (HPT series)

Product features: true multi-cylinder fixed spindle, high-speed laminated crushing chamber, liner without backing material, more reliable sealing, full hydraulic operation, full automatic control system

Previous: SMP Crusher

Next: SMP Crusher

The complete set of sand and gravel aggregate production line equipment mainly consists of crushing equipment, sand making equipment and auxiliary equipment. The main equipment is introduced below:1. Jaw crusher (C6X series)

The complete set of sand and gravel aggregate production line equipment mainly consists of crushing equipment, sand making equipment and auxiliary equipment. The main equipment is introduced below:

1. Jaw crusher (C6X series)

Product features: high-efficiency crushing chamber design, optimizing material crushing efficiency; combined frame, stable structure and flexible assembly. Integrated motor integration, strong power and easy maintenance. Foot-free elastic support, shock reduction and noise reduction. Hydraulic adjustment system, precise control of operating parameters. Fully automatic centralized lubrication, extending equipment life, reducing downtime maintenance, and comprehensively improving crushing operation efficiency and stability.

2. Impact crusher (CI5X series)

Product features: high-speed crushing efficiency, heavy-duty rotor with large inertia and high precision; high wear-resistant materials enhance durability, full hydraulic operation is multifunctional and convenient, and the overall performance is excellent.

3. Multi-cylinder hydraulic cone crusher (HPT series)

Product features: true multi-cylinder fixed spindle, high-speed laminated crushing chamber, liner without backing material, more reliable sealing, full hydraulic operation, full automatic control system

Previous: SMP Crusher

Next: SMP Crusher

How to choose crushing equipment for large-scale crushing production lines in mines

How to choose crushing equipment for large-scale crushing production lines in mines What is the complete set of sand and gravel aggregate production line equipment? How much does it cost?

What is the complete set of sand and gravel aggregate production line equipment? How much does it cost? How to control dust and noise pollution in the new sand and gravel production line of stone quarry

How to control dust and noise pollution in the new sand and gravel production line of stone quarry What are the advantages of 200 tons per hour mobile stone crusher

What are the advantages of 200 tons per hour mobile stone crusher How to choose limestone crushing equipment? How much does limestone crushing equipment cost?

How to choose limestone crushing equipment? How much does limestone crushing equipment cost? How to choose crushing equipment for large-scale crushing production lines in mines

How to choose crushing equipment for large-scale crushing production lines in mines What is the complete set of sand and gravel aggregate production line equipment? How much does it cost?

What is the complete set of sand and gravel aggregate production line equipment? How much does it cost? How to control dust and noise pollution in the new sand and gravel production line of stone quarry

How to control dust and noise pollution in the new sand and gravel production line of stone quarry What are the advantages of 200 tons per hour mobile stone crusher

What are the advantages of 200 tons per hour mobile stone crusher How to choose limestone crushing equipment? How much does limestone crushing equipment cost?

How to choose limestone crushing equipment? How much does limestone crushing equipment cost?