The models of Shibang Group's 100-ton stone cone crusher are as follows:1. Single-cylinder hydraulic cone crusher - recommended model: HST160H1Processing capacity: 66-210t/hFeed size: 0-185mm

The models of Shibang Group's 100-ton stone cone crusher are as follows:

1. Single-cylinder hydraulic cone crusher - recommended model: HST160H1

Processing capacity: 66-210t/h

Feed size: 0-185mm

Applicable materials: granite, diabase, basalt, river pebbles, limestone, dolomite, metal ore and non-metallic ore, etc.

Click here to consult for cone crusher prices

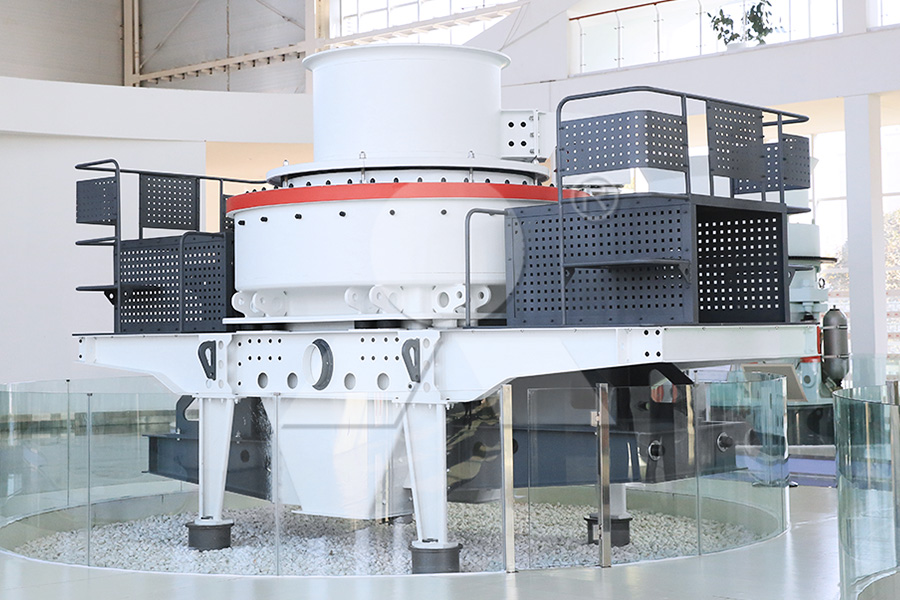

The single-cylinder cone crusher combines the essence of electrical, hydraulic and mechanical technologies. Its innovative design, including the optimized laminated crushing cavity, has achieved a structural leap. The unique bottom single-cylinder structure not only directly controls the discharge port, but also effectively prevents iron from passing through and conveniently clears the cavity. The three major functions are integrated into one. In addition, the machine is equipped with a variety of cavity options to flexibly respond to various crushing needs, showing excellent adaptability and efficiency. It is an industry-leading crushing solution.

2. Multi-cylinder hydraulic cone crusher - recommended model: HPT200F1

Processing capacity: 100-220t/h

Feed size: 0-95mm

Applicable materials: granite, diabase, basalt, river pebbles, limestone, dolomite, metal ore and non-metallic ore, etc.

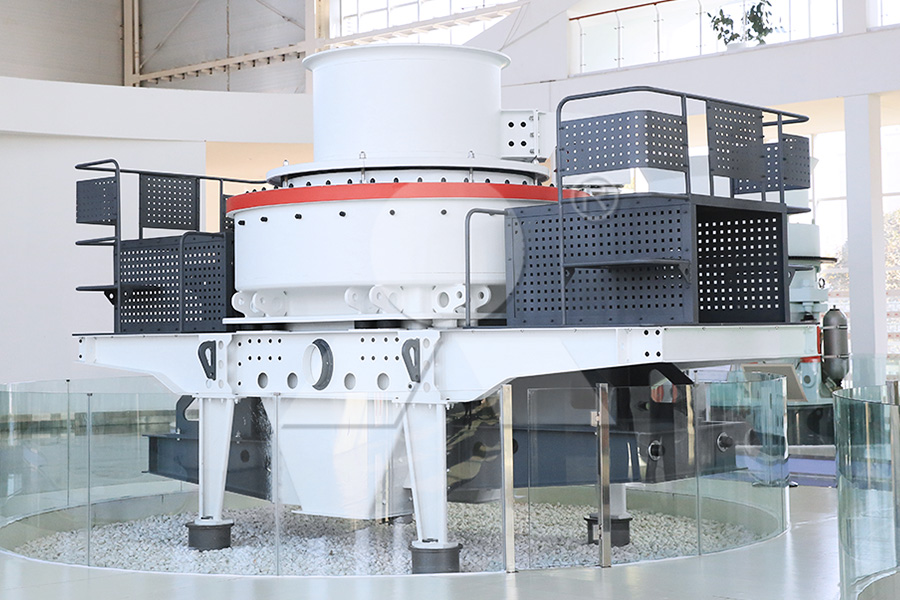

Multi-cylinder hydraulic cone crusher combines high efficiency and flexibility, and provides five-level chamber options from C1 to F2 (C1 ultra-coarse to F2 ultra-fine), accurately matching various crushing needs. Its unique fixed-axis design combined with laminated crushing technology ensures uniform particle size, excellent particle shape, close to cube, and improves material value.

How much is it?

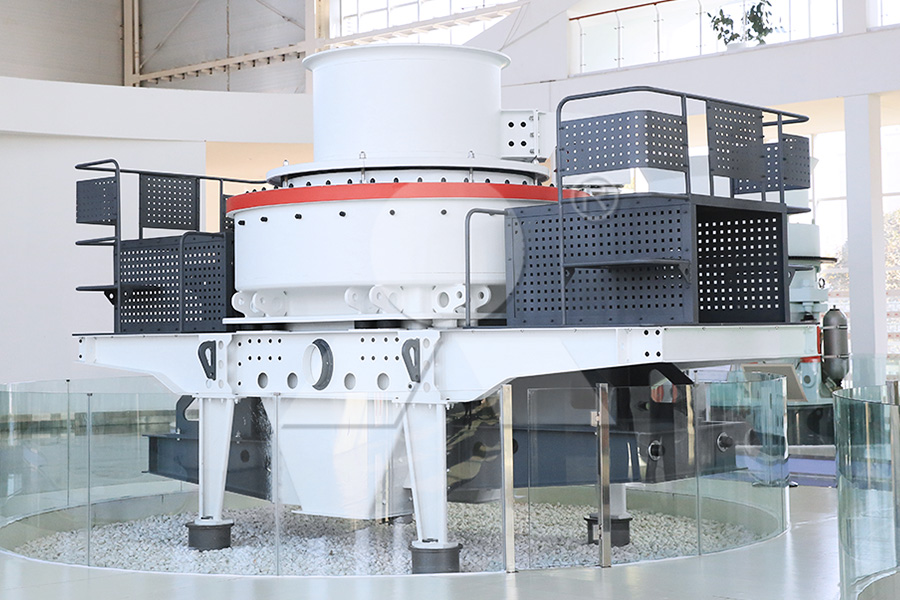

The above models are only recommended models, and the price range is between hundreds of thousands and millions. The price difference is mainly due to the different functions and advanced levels of each model, and the performance in the later production is also different. The external factors are mainly different manufacturers, resulting in different equipment quality, configuration, and pricing.

Previous: SMP Crusher

Next: SMP Crusher

The models of Shibang Group's 100-ton stone cone crusher are as follows:1. Single-cylinder hydraulic cone crusher - recommended model: HST160H1Processing capacity: 66-210t/hFeed size: 0-185mm

The models of Shibang Group's 100-ton stone cone crusher are as follows:

1. Single-cylinder hydraulic cone crusher - recommended model: HST160H1

Processing capacity: 66-210t/h

Feed size: 0-185mm

Applicable materials: granite, diabase, basalt, river pebbles, limestone, dolomite, metal ore and non-metallic ore, etc.

Click here to consult for cone crusher prices

The single-cylinder cone crusher combines the essence of electrical, hydraulic and mechanical technologies. Its innovative design, including the optimized laminated crushing cavity, has achieved a structural leap. The unique bottom single-cylinder structure not only directly controls the discharge port, but also effectively prevents iron from passing through and conveniently clears the cavity. The three major functions are integrated into one. In addition, the machine is equipped with a variety of cavity options to flexibly respond to various crushing needs, showing excellent adaptability and efficiency. It is an industry-leading crushing solution.

2. Multi-cylinder hydraulic cone crusher - recommended model: HPT200F1

Processing capacity: 100-220t/h

Feed size: 0-95mm

Applicable materials: granite, diabase, basalt, river pebbles, limestone, dolomite, metal ore and non-metallic ore, etc.

Multi-cylinder hydraulic cone crusher combines high efficiency and flexibility, and provides five-level chamber options from C1 to F2 (C1 ultra-coarse to F2 ultra-fine), accurately matching various crushing needs. Its unique fixed-axis design combined with laminated crushing technology ensures uniform particle size, excellent particle shape, close to cube, and improves material value.

How much is it?

The above models are only recommended models, and the price range is between hundreds of thousands and millions. The price difference is mainly due to the different functions and advanced levels of each model, and the performance in the later production is also different. The external factors are mainly different manufacturers, resulting in different equipment quality, configuration, and pricing.

Previous: SMP Crusher

Next: SMP Crusher

Equipment selection and production line configuration for crushing and processing bluestone

Equipment selection and production line configuration for crushing and processing bluestone How much does it cost to invest in a 3,000-ton-per-day gravel production line?

How much does it cost to invest in a 3,000-ton-per-day gravel production line? 1200 tons per hour gravel production line configuration

1200 tons per hour gravel production line configuration How to improve the efficiency of mobile stone crusher

How to improve the efficiency of mobile stone crusher What are the advantages of jaw crusher in crushing iron ore

What are the advantages of jaw crusher in crushing iron ore Equipment selection and production line configuration for crushing and processing bluestone

Equipment selection and production line configuration for crushing and processing bluestone How much does it cost to invest in a 3,000-ton-per-day gravel production line?

How much does it cost to invest in a 3,000-ton-per-day gravel production line? 1200 tons per hour gravel production line configuration

1200 tons per hour gravel production line configuration How to improve the efficiency of mobile stone crusher

How to improve the efficiency of mobile stone crusher What are the advantages of jaw crusher in crushing iron ore

What are the advantages of jaw crusher in crushing iron ore