The following equipment is required for a 5,000-ton gravel production line per day:Click here to learn about the price of gravel production line equipmentVibrating feeder: This equipment is mainly used to transport raw stones

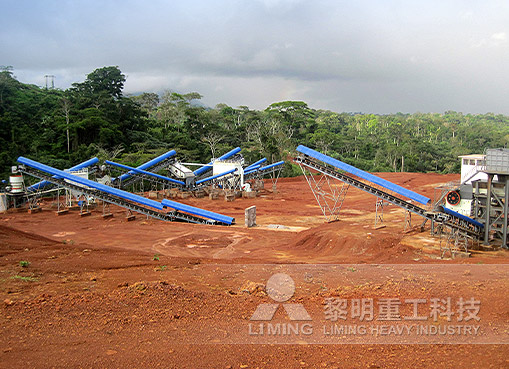

The following equipment is required for a 5,000-ton gravel production line per day:

Click here to learn about the price of gravel production line equipment

Vibrating feeder: This equipment is mainly used to transport raw stones to the crusher at a uniform speed. During the transportation process, it can perform preliminary screening of the raw materials and separate the mud powder through a specific device to avoid mixing with mud powder, thereby effectively ensuring the purity of the stones entering the crusher and improving the quality of the crushed products.

Crusher: This equipment plays a key role in stone processing and is mainly responsible for crushing the raw stones. Among them, the jaw crusher, with its strong bite force, undertakes the task of coarse crushing and preliminarily cracks large pieces of stone; the impact crusher uses the impact effect to perform medium and fine crushing, further refining the stone to meet the needs of different particle sizes.

Vibrating screening machine: This equipment is mainly used to process crushed stones and undertakes the screening task in the entire sand and gravel production process. It can accurately separate stones of different specifications through a specific screen structure and a vibration device. Whether it is coarse gravel with larger particle size or fine gravel with smaller particle size, it can be screened in an orderly manner to meet the diverse needs of construction materials.

Sand washing machine: used to wash gravel and remove powder from it.

Conveying equipment: belt conveyor, used to transport crushed gravel from one process to another to achieve automated production.

Storage equipment: used to store crushed gravel for subsequent use, such as transfer silos.

Auxiliary equipment: such as dust removal equipment, sewage sedimentation tanks, etc., to ensure the smooth operation of the production line and the compliance with environmental protection requirements.

Investment cost:

Equipment purchase fee: The price of equipment fluctuates due to scale and brand awareness, usually ranging from millions to tens of millions of yuan. For example, a small basic model may cost millions, while a large well-known brand may be close to or even exceed tens of millions of yuan. In addition, when purchasing, additional expenses such as equipment transportation fees, installation and commissioning fees must be included in the budget to avoid omissions in capital planning.

Site rental fee: The size and location of the rental site will directly affect the layout and operating efficiency of the production line. The rent varies according to the region and site area, generally ranging from tens of thousands to hundreds of thousands of yuan.

Labor cost: The operation of the production line requires a certain amount of staffing, including operators, maintenance workers, management personnel, etc. Labor costs vary according to the region and the number of personnel, and a reasonable budget needs to be made based on the actual situation.

Previous: SMP Crusher

Next: SMP Crusher

The following equipment is required for a 5,000-ton gravel production line per day:Click here to learn about the price of gravel production line equipmentVibrating feeder: This equipment is mainly used to transport raw stones

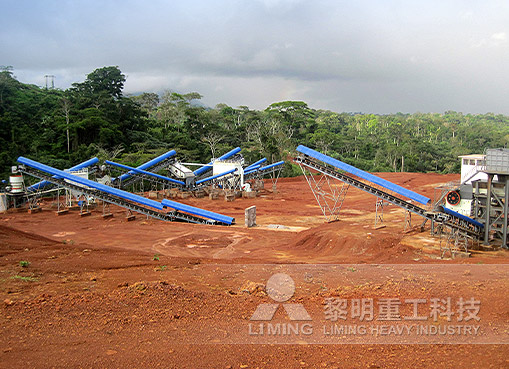

The following equipment is required for a 5,000-ton gravel production line per day:

Click here to learn about the price of gravel production line equipment

Vibrating feeder: This equipment is mainly used to transport raw stones to the crusher at a uniform speed. During the transportation process, it can perform preliminary screening of the raw materials and separate the mud powder through a specific device to avoid mixing with mud powder, thereby effectively ensuring the purity of the stones entering the crusher and improving the quality of the crushed products.

Crusher: This equipment plays a key role in stone processing and is mainly responsible for crushing the raw stones. Among them, the jaw crusher, with its strong bite force, undertakes the task of coarse crushing and preliminarily cracks large pieces of stone; the impact crusher uses the impact effect to perform medium and fine crushing, further refining the stone to meet the needs of different particle sizes.

Vibrating screening machine: This equipment is mainly used to process crushed stones and undertakes the screening task in the entire sand and gravel production process. It can accurately separate stones of different specifications through a specific screen structure and a vibration device. Whether it is coarse gravel with larger particle size or fine gravel with smaller particle size, it can be screened in an orderly manner to meet the diverse needs of construction materials.

Sand washing machine: used to wash gravel and remove powder from it.

Conveying equipment: belt conveyor, used to transport crushed gravel from one process to another to achieve automated production.

Storage equipment: used to store crushed gravel for subsequent use, such as transfer silos.

Auxiliary equipment: such as dust removal equipment, sewage sedimentation tanks, etc., to ensure the smooth operation of the production line and the compliance with environmental protection requirements.

Investment cost:

Equipment purchase fee: The price of equipment fluctuates due to scale and brand awareness, usually ranging from millions to tens of millions of yuan. For example, a small basic model may cost millions, while a large well-known brand may be close to or even exceed tens of millions of yuan. In addition, when purchasing, additional expenses such as equipment transportation fees, installation and commissioning fees must be included in the budget to avoid omissions in capital planning.

Site rental fee: The size and location of the rental site will directly affect the layout and operating efficiency of the production line. The rent varies according to the region and site area, generally ranging from tens of thousands to hundreds of thousands of yuan.

Labor cost: The operation of the production line requires a certain amount of staffing, including operators, maintenance workers, management personnel, etc. Labor costs vary according to the region and the number of personnel, and a reasonable budget needs to be made based on the actual situation.

Previous: SMP Crusher

Next: SMP Crusher

How much is a mining crusher

How much is a mining crusher CI5X large stone crushing equipment performance characteristics

CI5X large stone crushing equipment performance characteristics How to choose a granite sand making machine? How much does a granite sand production line cost?

How to choose a granite sand making machine? How much does a granite sand production line cost? Which crusher is suitable for processing high hardness concrete recycled materials?

Which crusher is suitable for processing high hardness concrete recycled materials? Large stone equipment production line equipment

Large stone equipment production line equipment How much is a mining crusher

How much is a mining crusher CI5X large stone crushing equipment performance characteristics

CI5X large stone crushing equipment performance characteristics How to choose a granite sand making machine? How much does a granite sand production line cost?

How to choose a granite sand making machine? How much does a granite sand production line cost? Which crusher is suitable for processing high hardness concrete recycled materials?

Which crusher is suitable for processing high hardness concrete recycled materials? Large stone equipment production line equipment

Large stone equipment production line equipment