For ores with higher hardness, it is crucial to choose the right crusher. Jaw crusher, gyratory crusher and cone crusher are all highly recommended crushers for crushing hard rocks. If you need to produce fine sand of 0-5mm, you need to add an impact c

For ores with higher hardness, it is crucial to choose the right crusher. Jaw crusher, gyratory crusher and cone crusher are all highly recommended crushers for crushing hard rocks. If you need to produce fine sand of 0-5mm, you need to add an impact crusher for shaping.

Hard rock crushing and sand making equipment selection click to consult

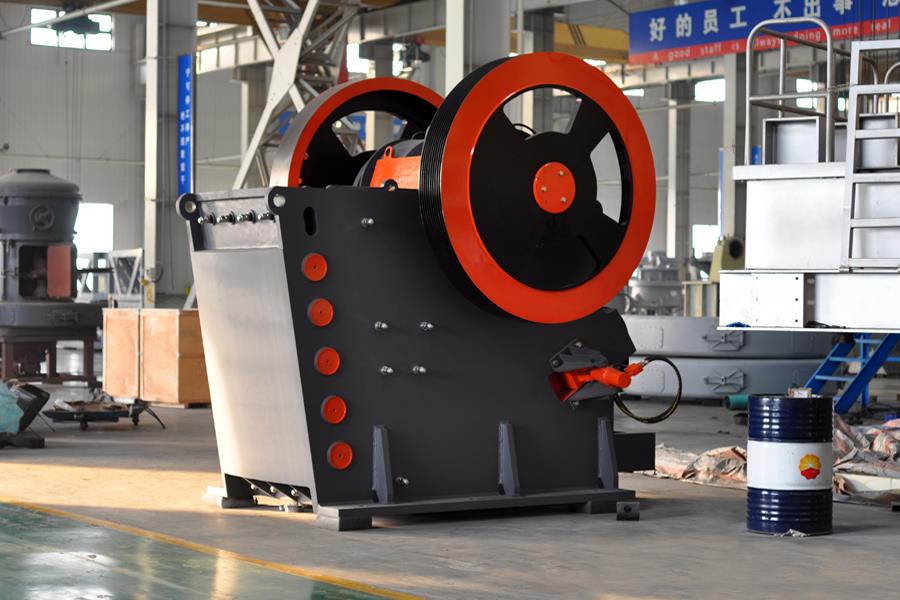

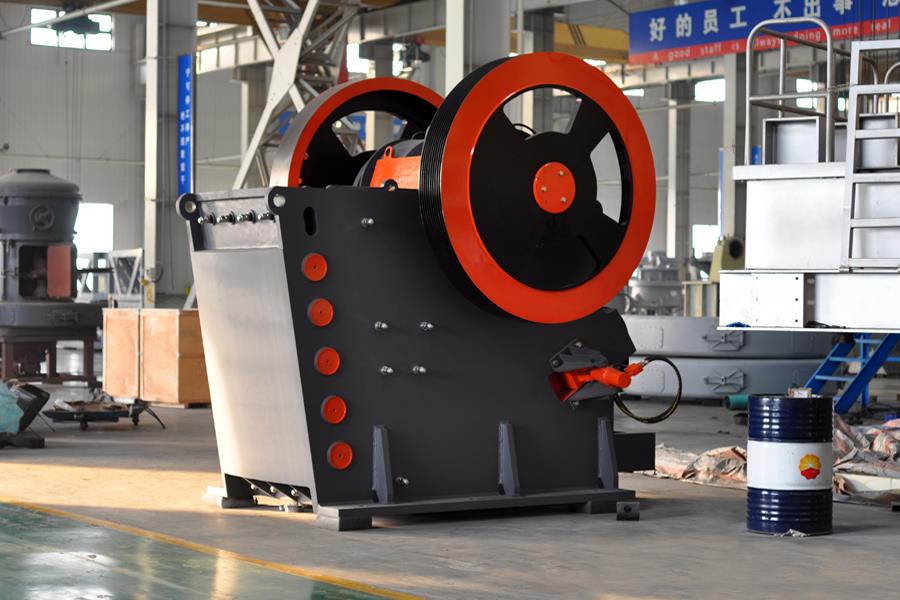

Jaw crusher or gyratory crusher:

As a widely used crusher model, the jaw crusher is known for its excellent crushing capacity and wide adaptability. Its working principle is based on the movement of the swinging jaw plate. Through this mechanism, the jaw crusher can efficiently crush the ore. Especially when facing ores with higher hardness, such as basalt, the jaw crusher shows extraordinary performance. It can easily crush these hard ores into smaller particles, providing a solid foundation for subsequent more refined crushing work.

Gyratory crushers perform well in coarse crushing of ores. Although their price is higher than that of jaw crushers, their output is higher than the latter. With its high speed and strong crushing force, gyratory crushers can efficiently handle ores with higher hardness, such as basalt.

Cone crusher: efficient medium and fine crusher

As a common hard rock crushing equipment, cone crusher can perform good medium and fine crushing of ore. Therefore, it is more suitable for processing basalt, an ore with higher hardness.

Impact crusher: a must for producing fine sand

If you need to produce 0-5mm fine sand, in addition to the crusher mentioned above, you can also add an impact crusher to shape it, so as to obtain the required fine sand.

Previous: SMP Crusher

Next: SMP Crusher

For ores with higher hardness, it is crucial to choose the right crusher. Jaw crusher, gyratory crusher and cone crusher are all highly recommended crushers for crushing hard rocks. If you need to produce fine sand of 0-5mm, you need to add an impact c

For ores with higher hardness, it is crucial to choose the right crusher. Jaw crusher, gyratory crusher and cone crusher are all highly recommended crushers for crushing hard rocks. If you need to produce fine sand of 0-5mm, you need to add an impact crusher for shaping.

Hard rock crushing and sand making equipment selection click to consult

Jaw crusher or gyratory crusher:

As a widely used crusher model, the jaw crusher is known for its excellent crushing capacity and wide adaptability. Its working principle is based on the movement of the swinging jaw plate. Through this mechanism, the jaw crusher can efficiently crush the ore. Especially when facing ores with higher hardness, such as basalt, the jaw crusher shows extraordinary performance. It can easily crush these hard ores into smaller particles, providing a solid foundation for subsequent more refined crushing work.

Gyratory crushers perform well in coarse crushing of ores. Although their price is higher than that of jaw crushers, their output is higher than the latter. With its high speed and strong crushing force, gyratory crushers can efficiently handle ores with higher hardness, such as basalt.

Cone crusher: efficient medium and fine crusher

As a common hard rock crushing equipment, cone crusher can perform good medium and fine crushing of ore. Therefore, it is more suitable for processing basalt, an ore with higher hardness.

Impact crusher: a must for producing fine sand

If you need to produce 0-5mm fine sand, in addition to the crusher mentioned above, you can also add an impact crusher to shape it, so as to obtain the required fine sand.

Previous: SMP Crusher

Next: SMP Crusher

Mobile integrated sand and gravel crusher: a new choice for efficient sand making

Mobile integrated sand and gravel crusher: a new choice for efficient sand making Analysis of the characteristics of Liming impact crusher

Analysis of the characteristics of Liming impact crusher Introduction to Cone Crusher Performance and Advantages

Introduction to Cone Crusher Performance and Advantages Three key factors for stone factories to choose sand making and crushing equipment: quality, reliability and price

Three key factors for stone factories to choose sand making and crushing equipment: quality, reliability and price Crusher manufacturers explain how to choose sand making equipment for gravel and sand material field

Crusher manufacturers explain how to choose sand making equipment for gravel and sand material field Mobile integrated sand and gravel crusher: a new choice for efficient sand making

Mobile integrated sand and gravel crusher: a new choice for efficient sand making Analysis of the characteristics of Liming impact crusher

Analysis of the characteristics of Liming impact crusher Introduction to Cone Crusher Performance and Advantages

Introduction to Cone Crusher Performance and Advantages Three key factors for stone factories to choose sand making and crushing equipment: quality, reliability and price

Three key factors for stone factories to choose sand making and crushing equipment: quality, reliability and price Crusher manufacturers explain how to choose sand making equipment for gravel and sand material field

Crusher manufacturers explain how to choose sand making equipment for gravel and sand material field