Project OverviewProcessing capacity: 7 million tons/ton per yearHourly production scale: 1,500 tons/hourRaw material variety: tuffClick here to consult for more information on

Project Overview

Processing capacity: 7 million tons/ton per year

Hourly production scale: 1,500 tons/hour

Raw material variety: tuff

Click here to consult for more information on the sand and gravel production line construction plan

Finished product specifications:

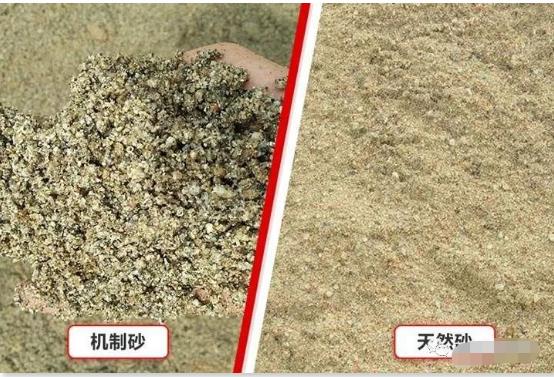

1. 0-5mm high-quality machine-made sand

2. 5-10-20mm first-grade crushed stone

3. 7-13-25mm standard crushed stone

Core equipment:

1. F5X heavy-duty feeding system

2. HPT hydraulic cone crusher host

3. VSI6X high-efficiency shaping sand making machine

4. S5X multi-layer vibration screening system

Process flow: wet classification production

Application area: highway/grade highway construction

Shibang has carried out strategic cooperation with Zhejiang Jiaotong Group and successfully implemented a series of key projects in the fields of limestone, basalt and tuff processing. This tuff production line adopts the "three crushing, two washing and one finishing" process plan, and the dual-line parallel design ensures stable production capacity. The multi-graded aggregates produced by the system perform well in terms of strength, particle shape and other indicators, providing reliable raw material guarantees for major infrastructure projects.

Sustainable development practice The implementation of this project fully responds to the national green development strategy and improves resource utilization efficiency through technological innovation. The overall design of the project follows the industry environmental protection standards and mainly reflects the following characteristics:

1. Environmentally friendly design The introduction of a fully enclosed production plant controls dust and noise emissions from the source. Combined with the wet production process, the powder content of the finished product is significantly reduced, and the product cleanliness is maintained at a high level. The construction of the mining area focuses on ecological restoration and achieves a harmonious unity between the production area and the natural environment.

2. Intelligent manufacturing system The central control system is equipped with the following functions:

1. Real-time monitoring of the operating parameters of each section

2. Visual display of the entire production process

3. Automatic recording of key process data

4. Remote diagnosis of equipment operation status Through intelligent transformation, the production management efficiency and process stability have been greatly improved.

Highlights of technological innovation

1. Multi-stage crushing process achieves precise particle size control

2. Hydraulic system ensures stable and reliable operation of equipment

3. Modular design facilitates later capacity expansion

4. Energy-saving and consumption-reducing technology reduces unit energy consumption

The project provides a reference example of transformation and upgrading for the sand and gravel aggregate industry by optimizing equipment configuration and innovating process solutions. In the future, it will continue to explore more efficient and environmentally friendly production models to help the high-quality development of the infrastructure industry.

Previous: SMP Crusher

Next: SMP Crusher

Project OverviewProcessing capacity: 7 million tons/ton per yearHourly production scale: 1,500 tons/hourRaw material variety: tuffClick here to consult for more information on

Project Overview

Processing capacity: 7 million tons/ton per year

Hourly production scale: 1,500 tons/hour

Raw material variety: tuff

Click here to consult for more information on the sand and gravel production line construction plan

Finished product specifications:

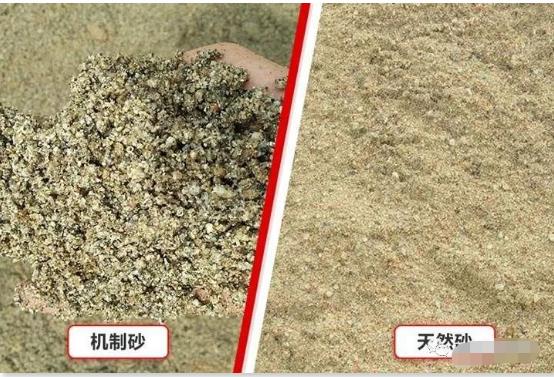

1. 0-5mm high-quality machine-made sand

2. 5-10-20mm first-grade crushed stone

3. 7-13-25mm standard crushed stone

Core equipment:

1. F5X heavy-duty feeding system

2. HPT hydraulic cone crusher host

3. VSI6X high-efficiency shaping sand making machine

4. S5X multi-layer vibration screening system

Process flow: wet classification production

Application area: highway/grade highway construction

Shibang has carried out strategic cooperation with Zhejiang Jiaotong Group and successfully implemented a series of key projects in the fields of limestone, basalt and tuff processing. This tuff production line adopts the "three crushing, two washing and one finishing" process plan, and the dual-line parallel design ensures stable production capacity. The multi-graded aggregates produced by the system perform well in terms of strength, particle shape and other indicators, providing reliable raw material guarantees for major infrastructure projects.

Sustainable development practice The implementation of this project fully responds to the national green development strategy and improves resource utilization efficiency through technological innovation. The overall design of the project follows the industry environmental protection standards and mainly reflects the following characteristics:

1. Environmentally friendly design The introduction of a fully enclosed production plant controls dust and noise emissions from the source. Combined with the wet production process, the powder content of the finished product is significantly reduced, and the product cleanliness is maintained at a high level. The construction of the mining area focuses on ecological restoration and achieves a harmonious unity between the production area and the natural environment.

2. Intelligent manufacturing system The central control system is equipped with the following functions:

1. Real-time monitoring of the operating parameters of each section

2. Visual display of the entire production process

3. Automatic recording of key process data

4. Remote diagnosis of equipment operation status Through intelligent transformation, the production management efficiency and process stability have been greatly improved.

Highlights of technological innovation

1. Multi-stage crushing process achieves precise particle size control

2. Hydraulic system ensures stable and reliable operation of equipment

3. Modular design facilitates later capacity expansion

4. Energy-saving and consumption-reducing technology reduces unit energy consumption

The project provides a reference example of transformation and upgrading for the sand and gravel aggregate industry by optimizing equipment configuration and innovating process solutions. In the future, it will continue to explore more efficient and environmentally friendly production models to help the high-quality development of the infrastructure industry.

Previous: SMP Crusher

Next: SMP Crusher

Liming Heavy Industry VU Aggregate Optimization System: A Successful Example of Product Optimization

Liming Heavy Industry VU Aggregate Optimization System: A Successful Example of Product Optimization Liming Heavy Industry Mobile Crushing Station: The Optimization and Upgrading Road to Break Through Bottlenecks

Liming Heavy Industry Mobile Crushing Station: The Optimization and Upgrading Road to Break Through Bottlenecks Gravel production line: optimization and upgrading, new vitality

Gravel production line: optimization and upgrading, new vitality Is it better to choose a single-cylinder or multi-cylinder cone crusher?

Is it better to choose a single-cylinder or multi-cylinder cone crusher? Guide to choosing and avoiding pitfalls in sand and gravel mining equipment: these details determine production efficiency

Guide to choosing and avoiding pitfalls in sand and gravel mining equipment: these details determine production efficiency Liming Heavy Industry VU Aggregate Optimization System: A Successful Example of Product Optimization

Liming Heavy Industry VU Aggregate Optimization System: A Successful Example of Product Optimization Liming Heavy Industry Mobile Crushing Station: The Optimization and Upgrading Road to Break Through Bottlenecks

Liming Heavy Industry Mobile Crushing Station: The Optimization and Upgrading Road to Break Through Bottlenecks Gravel production line: optimization and upgrading, new vitality

Gravel production line: optimization and upgrading, new vitality Is it better to choose a single-cylinder or multi-cylinder cone crusher?

Is it better to choose a single-cylinder or multi-cylinder cone crusher? Guide to choosing and avoiding pitfalls in sand and gravel mining equipment: these details determine production efficiency

Guide to choosing and avoiding pitfalls in sand and gravel mining equipment: these details determine production efficiency