With the rapid development of modern construction and infrastructure, the demand for crushed stone is increasing. The 1,000-ton-per-hour stone crusher complete set has become the core of large-scale stone production lines, which can meet the market'

With the rapid development of modern construction and infrastructure, the demand for crushed stone is increasing. The 1,000-ton-per-hour stone crusher complete set has become the core of large-scale stone production lines, which can meet the market's requirements for high efficiency and environmental protection.

Consult more complete production line equipment

High efficiency, widely applicable

The 1,000-ton-per-hour stone crusher complete set can crush a wide variety of materials, including more than 200 materials such as pebbles, limestone, and basalt. With the continuous rise in stone prices, more and more customers choose to invest in stone production lines. Under the influence of environmental protection policies, energy-saving and environmentally friendly equipment is particularly favored.

Successful case sharing

Take the customer in Yichang, Hubei as an example. After visiting the Red Star plant, the customer decided to adopt the 1,000-ton-per-hour limestone production line solution designed by Red Star. After production, it saves more than 100,000 yuan in costs each year, which fully reflects the efficient return on investment.

Complete set of equipment composition

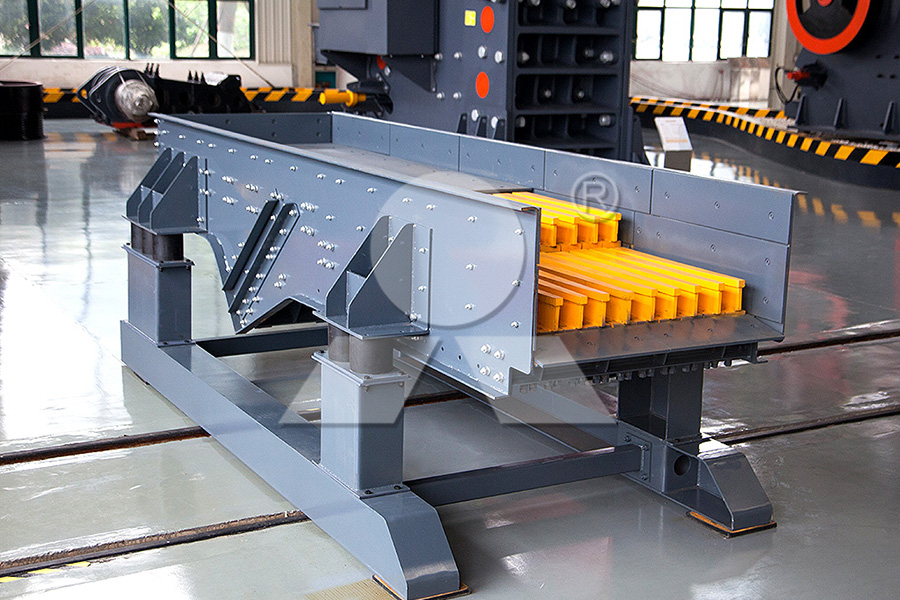

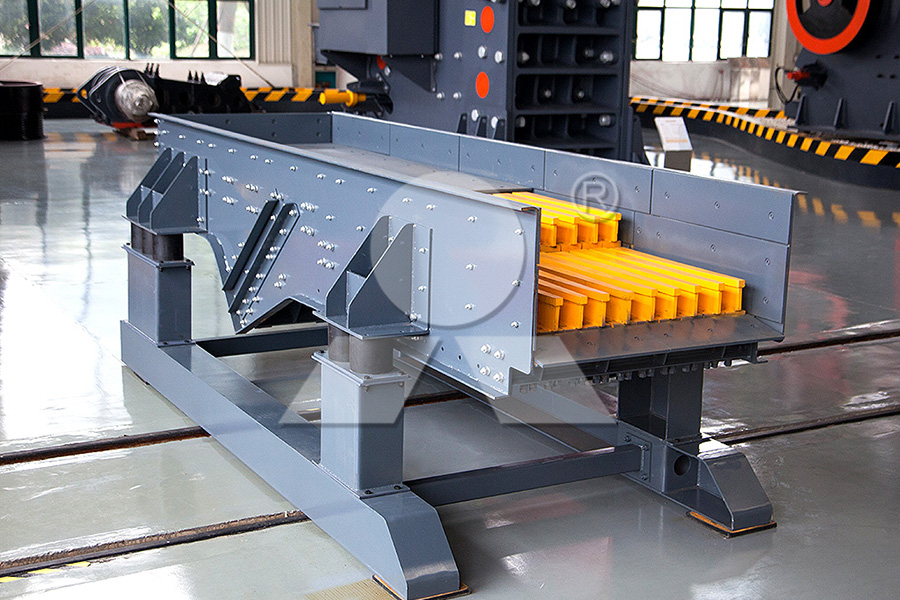

The equipment configuration of the production line includes a vibrating feeder, a jaw crusher, an impact crusher and multiple conveyors. The simplified design not only reduces the floor space, but also reduces the investment cost, which is very suitable for customer needs.

Production process

The entire production process is efficient and reasonable. The raw materials are transported to the jaw crusher through the feeder for coarse crushing, then finely crushed by the impact crusher, and finally the finished stones of different specifications are screened by vibration to meet the diversified market needs.

Investment analysis

The investment cost of a 1,000-ton stone crusher per hour is affected by many factors, including equipment model, design rationality and customer needs. Although the cost of choosing advanced equipment is slightly higher, its energy-saving effect and later economic benefits are significant.

Previous: SMP Crusher

Next: SMP Crusher

With the rapid development of modern construction and infrastructure, the demand for crushed stone is increasing. The 1,000-ton-per-hour stone crusher complete set has become the core of large-scale stone production lines, which can meet the market'

With the rapid development of modern construction and infrastructure, the demand for crushed stone is increasing. The 1,000-ton-per-hour stone crusher complete set has become the core of large-scale stone production lines, which can meet the market's requirements for high efficiency and environmental protection.

Consult more complete production line equipment

High efficiency, widely applicable

The 1,000-ton-per-hour stone crusher complete set can crush a wide variety of materials, including more than 200 materials such as pebbles, limestone, and basalt. With the continuous rise in stone prices, more and more customers choose to invest in stone production lines. Under the influence of environmental protection policies, energy-saving and environmentally friendly equipment is particularly favored.

Successful case sharing

Take the customer in Yichang, Hubei as an example. After visiting the Red Star plant, the customer decided to adopt the 1,000-ton-per-hour limestone production line solution designed by Red Star. After production, it saves more than 100,000 yuan in costs each year, which fully reflects the efficient return on investment.

Complete set of equipment composition

The equipment configuration of the production line includes a vibrating feeder, a jaw crusher, an impact crusher and multiple conveyors. The simplified design not only reduces the floor space, but also reduces the investment cost, which is very suitable for customer needs.

Production process

The entire production process is efficient and reasonable. The raw materials are transported to the jaw crusher through the feeder for coarse crushing, then finely crushed by the impact crusher, and finally the finished stones of different specifications are screened by vibration to meet the diversified market needs.

Investment analysis

The investment cost of a 1,000-ton stone crusher per hour is affected by many factors, including equipment model, design rationality and customer needs. Although the cost of choosing advanced equipment is slightly higher, its energy-saving effect and later economic benefits are significant.

Previous: SMP Crusher

Next: SMP Crusher

How to configure a 2000 tons per day sand and gravel production line

How to configure a 2000 tons per day sand and gravel production line What are the machines for processing gold ore?

What are the machines for processing gold ore? Mobile construction waste crushing station - construction waste recycling equipment

Mobile construction waste crushing station - construction waste recycling equipment Melon Seed Slice Stone Production and Equipment Selection

Melon Seed Slice Stone Production and Equipment Selection How much is a 3000 cubic meter sand production line per day

How much is a 3000 cubic meter sand production line per day How to configure a 2000 tons per day sand and gravel production line

How to configure a 2000 tons per day sand and gravel production line What are the machines for processing gold ore?

What are the machines for processing gold ore? Mobile construction waste crushing station - construction waste recycling equipment

Mobile construction waste crushing station - construction waste recycling equipment Melon Seed Slice Stone Production and Equipment Selection

Melon Seed Slice Stone Production and Equipment Selection How much is a 3000 cubic meter sand production line per day

How much is a 3000 cubic meter sand production line per day