The finished sand and gravel are of high quality and cleanThe 1,200-ton screening, crushing and washing production line system in Xianyang, Shaanxi is located in Shaanxi. The system mainly produces sand and gravel aggregates for cons

The finished sand and gravel are of high quality and clean

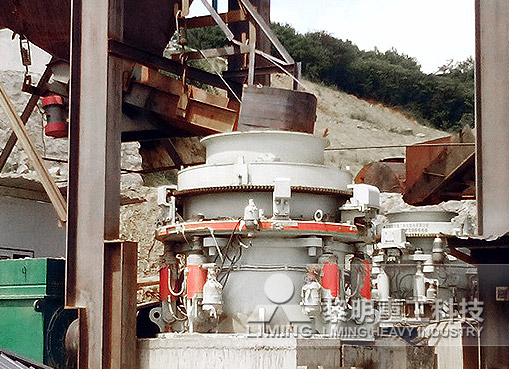

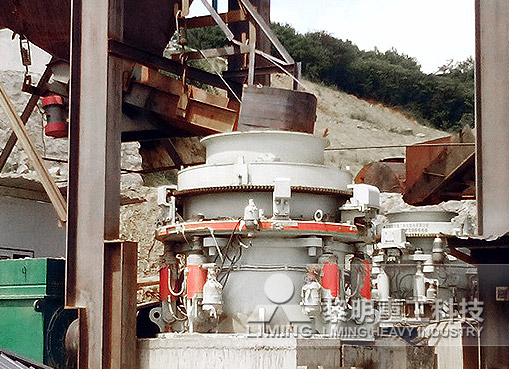

The 1,200-ton screening, crushing and washing production line system in Xianyang, Shaanxi is located in Shaanxi. The system mainly produces sand and gravel aggregates for construction, and the system design scale is 1,200t/h. The system is implemented by our company for process design, main equipment manufacturing, basic construction design, system guidance and installation, commissioning and training, and delivery and operation. Since the source of the project is excavated natural gravel and the soil content is high, the screening, washing and desludging processes of the system are emphasized in the system design. The raw materials are pre-screened with high-performance heavy-duty screens, and forced to be washed and desludged before entering the subsequent jaw crusher and HPY series multi-cylinder cone crusher. In order to ensure the production of clean sand and gravel aggregates, the system is designed for secondary screening and forced washing and desludging. Finally, the finished sand and gravel aggregates are washed and dehydrated again with special stone washing, sand washing and dehydration equipment to ensure the quality and cleanliness of the finished sand and gravel.

Process advantage description:

Based on the customer's on-site conditions and material characteristics, targeted system design is carried out:

1. The high-performance heavy-duty screen is configured to pre-screen the raw materials;

2. We have designed secondary screening and forced water washing and desludging for this project;

3. The optimized design ensures the quality and cleanliness of the finished sand and gravel.

Processing materials: granite gravel

Previous: SMP Crusher

Next: SMP Crusher

The finished sand and gravel are of high quality and cleanThe 1,200-ton screening, crushing and washing production line system in Xianyang, Shaanxi is located in Shaanxi. The system mainly produces sand and gravel aggregates for cons

The finished sand and gravel are of high quality and clean

The 1,200-ton screening, crushing and washing production line system in Xianyang, Shaanxi is located in Shaanxi. The system mainly produces sand and gravel aggregates for construction, and the system design scale is 1,200t/h. The system is implemented by our company for process design, main equipment manufacturing, basic construction design, system guidance and installation, commissioning and training, and delivery and operation. Since the source of the project is excavated natural gravel and the soil content is high, the screening, washing and desludging processes of the system are emphasized in the system design. The raw materials are pre-screened with high-performance heavy-duty screens, and forced to be washed and desludged before entering the subsequent jaw crusher and HPY series multi-cylinder cone crusher. In order to ensure the production of clean sand and gravel aggregates, the system is designed for secondary screening and forced washing and desludging. Finally, the finished sand and gravel aggregates are washed and dehydrated again with special stone washing, sand washing and dehydration equipment to ensure the quality and cleanliness of the finished sand and gravel.

Process advantage description:

Based on the customer's on-site conditions and material characteristics, targeted system design is carried out:

1. The high-performance heavy-duty screen is configured to pre-screen the raw materials;

2. We have designed secondary screening and forced water washing and desludging for this project;

3. The optimized design ensures the quality and cleanliness of the finished sand and gravel.

Processing materials: granite gravel

Previous: SMP Crusher

Next: SMP Crusher

1000 tons per hour coarse crushed sand and gravel aggregate processing production line in Marseille, France

1000 tons per hour coarse crushed sand and gravel aggregate processing production line in Marseille, France High-quality sand and gravel aggregate production line for Fiji national highway construction

High-quality sand and gravel aggregate production line for Fiji national highway construction Environmentally friendly sand and gravel processing production line of Jilin Dunhua Pumped Storage Power Station

Environmentally friendly sand and gravel processing production line of Jilin Dunhua Pumped Storage Power Station 300 tons per hour sand and gravel aggregate production line for hydropower station in Nam Ou River, Laos

300 tons per hour sand and gravel aggregate production line for hydropower station in Nam Ou River, Laos Malaysia 800 tons per hour construction aggregate production line

Malaysia 800 tons per hour construction aggregate production line 1000 tons per hour coarse crushed sand and gravel aggregate processing production line in Marseille, France

1000 tons per hour coarse crushed sand and gravel aggregate processing production line in Marseille, France High-quality sand and gravel aggregate production line for Fiji national highway construction

High-quality sand and gravel aggregate production line for Fiji national highway construction Environmentally friendly sand and gravel processing production line of Jilin Dunhua Pumped Storage Power Station

Environmentally friendly sand and gravel processing production line of Jilin Dunhua Pumped Storage Power Station 300 tons per hour sand and gravel aggregate production line for hydropower station in Nam Ou River, Laos

300 tons per hour sand and gravel aggregate production line for hydropower station in Nam Ou River, Laos Malaysia 800 tons per hour construction aggregate production line

Malaysia 800 tons per hour construction aggregate production line