Examples of configuration plans for a 300-ton-per-hour sand and gravel production line are as follows:Discharge particle size: 0-5mm, 5-10mm, 10-20mm, 20-31.5mm, 31.5-40mm

Examples of configuration plans for a 300-ton-per-hour sand and gravel production line are as follows:

Discharge particle size: 0-5mm, 5-10mm, 10-20mm, 20-31.5mm, 31.5-40mm

Host equipment: PE jaw crusher, HPT hydraulic cone crusher, HST hydraulic cone crusher, VSI6X sand making machine

Click here for consultation on sand and gravel production line construction plan and price

The main process is as follows:

Main equipment introduction:

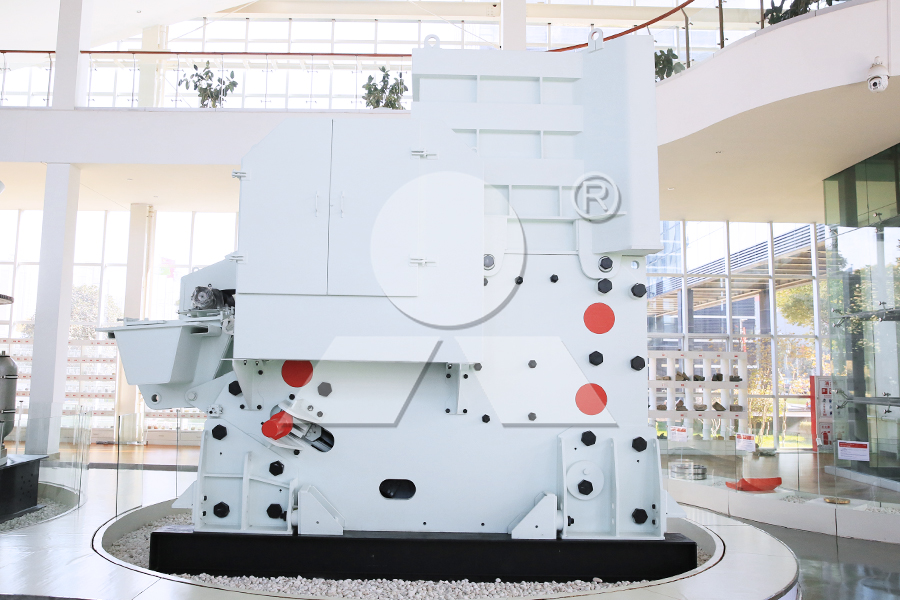

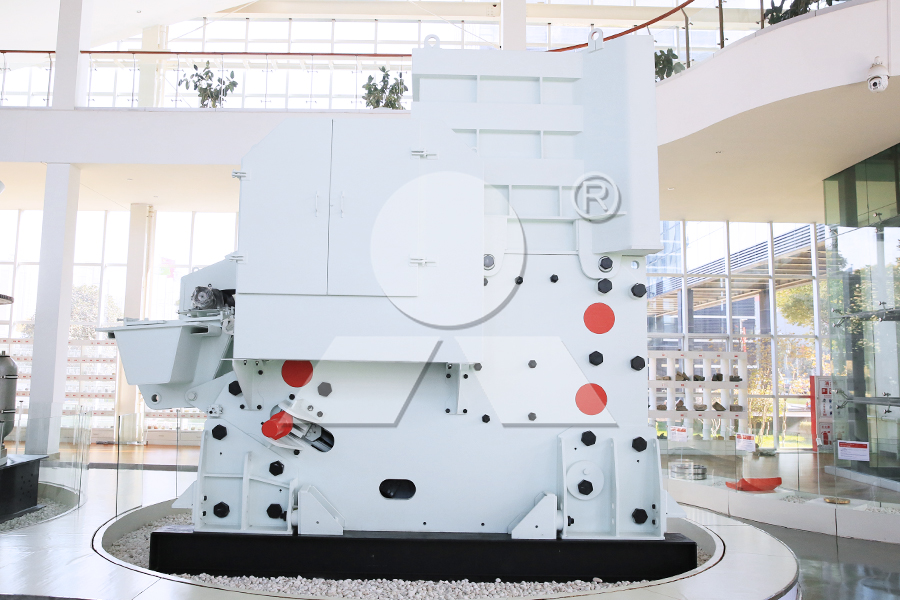

1. Jaw crusher:

The jaw crusher stands out with its efficient crushing cavity design, significant processing capacity, and can easily handle large flow of materials. Its combined frame structure is sturdy and durable, showing strong adaptability and stability, and is suitable for various scenarios such as ore mining and construction. The clever design of the integrated motor not only simplifies the installation process, but also improves the overall performance and ensures smooth and reliable operation of the equipment.

2. Cone crusher:

The cone crusher is an efficient medium and fine crushing equipment. It uses the laminated crushing principle to effectively ensure the excellent shape of the finished particles. The key components of the equipment are made of highly wear-resistant special materials. This design significantly enhances the durability of wearing parts, thereby significantly reducing the maintenance costs of the equipment.

3. Sand making machine:

The sand making machine significantly improves the crushing efficiency by optimizing the crushing cavity type, combining the "rock on stone" and "rock on iron" crushing methods, and specially designing lining materials and impact blocks according to the working conditions. At the same time, it is equipped with a simple lifting device to facilitate the lifting and maintenance of the impeller and bearing barrel without the assistance of large equipment, reducing the difficulty of maintenance.

Previous: SMP Crusher

Next: SMP Crusher

Examples of configuration plans for a 300-ton-per-hour sand and gravel production line are as follows:Discharge particle size: 0-5mm, 5-10mm, 10-20mm, 20-31.5mm, 31.5-40mm

Examples of configuration plans for a 300-ton-per-hour sand and gravel production line are as follows:

Discharge particle size: 0-5mm, 5-10mm, 10-20mm, 20-31.5mm, 31.5-40mm

Host equipment: PE jaw crusher, HPT hydraulic cone crusher, HST hydraulic cone crusher, VSI6X sand making machine

Click here for consultation on sand and gravel production line construction plan and price

The main process is as follows:

Main equipment introduction:

1. Jaw crusher:

The jaw crusher stands out with its efficient crushing cavity design, significant processing capacity, and can easily handle large flow of materials. Its combined frame structure is sturdy and durable, showing strong adaptability and stability, and is suitable for various scenarios such as ore mining and construction. The clever design of the integrated motor not only simplifies the installation process, but also improves the overall performance and ensures smooth and reliable operation of the equipment.

2. Cone crusher:

The cone crusher is an efficient medium and fine crushing equipment. It uses the laminated crushing principle to effectively ensure the excellent shape of the finished particles. The key components of the equipment are made of highly wear-resistant special materials. This design significantly enhances the durability of wearing parts, thereby significantly reducing the maintenance costs of the equipment.

3. Sand making machine:

The sand making machine significantly improves the crushing efficiency by optimizing the crushing cavity type, combining the "rock on stone" and "rock on iron" crushing methods, and specially designing lining materials and impact blocks according to the working conditions. At the same time, it is equipped with a simple lifting device to facilitate the lifting and maintenance of the impeller and bearing barrel without the assistance of large equipment, reducing the difficulty of maintenance.

Previous: SMP Crusher

Next: SMP Crusher

How to choose brick slag crushing equipment

How to choose brick slag crushing equipment 600 tons per hour gravel production line

600 tons per hour gravel production line The role of mobile screening equipment in sand and gravel aggregate production

The role of mobile screening equipment in sand and gravel aggregate production Calcite crushing equipment, what equipment is needed for calcite ore crushing

Calcite crushing equipment, what equipment is needed for calcite ore crushing What are the 1000 tons per hour calcite crushing equipment?

What are the 1000 tons per hour calcite crushing equipment? How to choose brick slag crushing equipment

How to choose brick slag crushing equipment 600 tons per hour gravel production line

600 tons per hour gravel production line The role of mobile screening equipment in sand and gravel aggregate production

The role of mobile screening equipment in sand and gravel aggregate production Calcite crushing equipment, what equipment is needed for calcite ore crushing

Calcite crushing equipment, what equipment is needed for calcite ore crushing What are the 1000 tons per hour calcite crushing equipment?

What are the 1000 tons per hour calcite crushing equipment?