How is the highly efficient and environmentally friendly configuration of this limestone crushing and sand making production line achieved? This article will explain in detail the unique configuration and significant advantages of this production line.

How is the highly efficient and environmentally friendly configuration of this limestone crushing and sand making production line achieved? This article will explain in detail the unique configuration and significant advantages of this production line. It not only represents the trend of large-scale, environmentally friendly, and efficient production, but has also won widespread market recognition.

More Limestone Crushing and Sand Making Production Lines with Larger Capacity

I. On-site Exploration of the Production Line

This limestone crushing and sand making production line, with its powerful production capacity, is making a significant contribution to local economic development.

II. High-Efficiency and Environmentally Friendly Limestone Crushing and Sand Making Production Line Equipment Configuration

Main Material: Limestone

Annual Designed Capacity: 1.2 million tons

Finished Product Specifications: 0-3mm high-quality manufactured sand, 3-8mm gravel, 8-31.5mm aggregate

Product Use: Direct supply to mixing plants to meet market demand

Daily Operating Hours: 20 hours

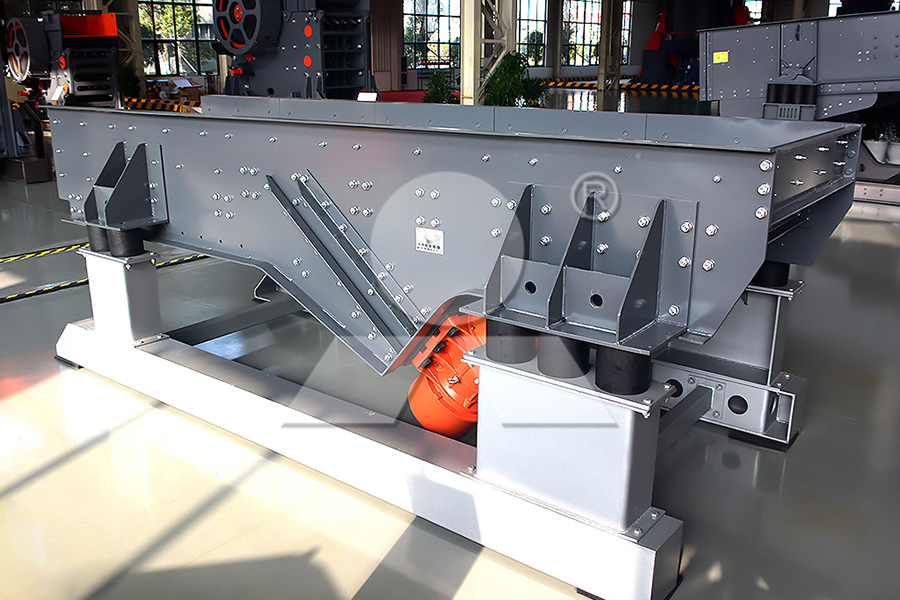

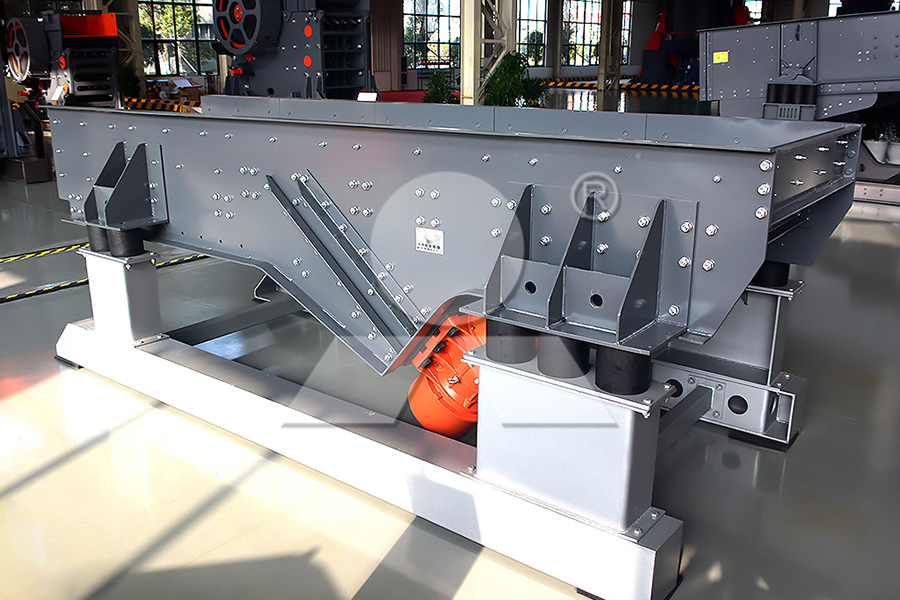

Core Equipment: CI5X impact crusher, VSI6X sand making machine, S5X vibrating screen, professional dust collector

III. Four Advantages of the 1.2 Million Ton/Year High-Efficiency and Environmentally Friendly Limestone Crushing and Sand Making Production Line

1. Intelligent Control, One-Button Operation: This production line adopts advanced technology and high-quality equipment. Its operation can be easily monitored and operated in the control room, achieving intelligent management.

2. Green and Environmentally Friendly: The production line adopts advanced dry production technology, with no wastewater discharge. The equipment operates in a semi-enclosed environment, equipped with professional dust collectors and dust covers, and uses spraying and other measures to effectively avoid dust pollution.

3. High Output and High Quality: Annual capacity of up to 1.2 million tons fully meets market demand. The produced aggregate has a perfect particle shape, and the manufactured sand is comparable in quality to river sand, possessing excellent characteristics.

4. Short construction period and rapid return on investment: From equipment delivery to installation and trial operation, it took only 80 days to achieve rapid production and return on investment, bringing substantial profits to investors.

This highly efficient and environmentally friendly limestone crushing and sand production line with an annual output of 1.2 million tons showcases advanced technology and high efficiency in modern mining production. With its advantages in green environmental protection and intelligent control, it injects new vitality into the sustainable development of the mining industry, becoming a benchmark project in the industry.

Previous: SMP Crusher

Next: SMP Crusher

How is the highly efficient and environmentally friendly configuration of this limestone crushing and sand making production line achieved? This article will explain in detail the unique configuration and significant advantages of this production line.

How is the highly efficient and environmentally friendly configuration of this limestone crushing and sand making production line achieved? This article will explain in detail the unique configuration and significant advantages of this production line. It not only represents the trend of large-scale, environmentally friendly, and efficient production, but has also won widespread market recognition.

More Limestone Crushing and Sand Making Production Lines with Larger Capacity

I. On-site Exploration of the Production Line

This limestone crushing and sand making production line, with its powerful production capacity, is making a significant contribution to local economic development.

II. High-Efficiency and Environmentally Friendly Limestone Crushing and Sand Making Production Line Equipment Configuration

Main Material: Limestone

Annual Designed Capacity: 1.2 million tons

Finished Product Specifications: 0-3mm high-quality manufactured sand, 3-8mm gravel, 8-31.5mm aggregate

Product Use: Direct supply to mixing plants to meet market demand

Daily Operating Hours: 20 hours

Core Equipment: CI5X impact crusher, VSI6X sand making machine, S5X vibrating screen, professional dust collector

III. Four Advantages of the 1.2 Million Ton/Year High-Efficiency and Environmentally Friendly Limestone Crushing and Sand Making Production Line

1. Intelligent Control, One-Button Operation: This production line adopts advanced technology and high-quality equipment. Its operation can be easily monitored and operated in the control room, achieving intelligent management.

2. Green and Environmentally Friendly: The production line adopts advanced dry production technology, with no wastewater discharge. The equipment operates in a semi-enclosed environment, equipped with professional dust collectors and dust covers, and uses spraying and other measures to effectively avoid dust pollution.

3. High Output and High Quality: Annual capacity of up to 1.2 million tons fully meets market demand. The produced aggregate has a perfect particle shape, and the manufactured sand is comparable in quality to river sand, possessing excellent characteristics.

4. Short construction period and rapid return on investment: From equipment delivery to installation and trial operation, it took only 80 days to achieve rapid production and return on investment, bringing substantial profits to investors.

This highly efficient and environmentally friendly limestone crushing and sand production line with an annual output of 1.2 million tons showcases advanced technology and high efficiency in modern mining production. With its advantages in green environmental protection and intelligent control, it injects new vitality into the sustainable development of the mining industry, becoming a benchmark project in the industry.

Previous: SMP Crusher

Next: SMP Crusher

How much does a mobile crushing plant cost? What factors influence the price?

How much does a mobile crushing plant cost? What factors influence the price? Introduction to Lead-Zinc Ore Crushing and Processing Technology and Related Cases

Introduction to Lead-Zinc Ore Crushing and Processing Technology and Related Cases How to Choose a Sand and Gravel Production Line Manufacturer

How to Choose a Sand and Gravel Production Line Manufacturer Configuration scheme for large-scale sand and gravel production line: 800-900tph limestone crushing production line

Configuration scheme for large-scale sand and gravel production line: 800-900tph limestone crushing production line Analysis of the distribution of sand and gravel mines in Guizhou Province and its surrounding areas, covering 1,582 sand and gravel mining rights.

Analysis of the distribution of sand and gravel mines in Guizhou Province and its surrounding areas, covering 1,582 sand and gravel mining rights. How much does a mobile crushing plant cost? What factors influence the price?

How much does a mobile crushing plant cost? What factors influence the price? Introduction to Lead-Zinc Ore Crushing and Processing Technology and Related Cases

Introduction to Lead-Zinc Ore Crushing and Processing Technology and Related Cases How to Choose a Sand and Gravel Production Line Manufacturer

How to Choose a Sand and Gravel Production Line Manufacturer Configuration scheme for large-scale sand and gravel production line: 800-900tph limestone crushing production line

Configuration scheme for large-scale sand and gravel production line: 800-900tph limestone crushing production line Analysis of the distribution of sand and gravel mines in Guizhou Province and its surrounding areas, covering 1,582 sand and gravel mining rights.

Analysis of the distribution of sand and gravel mines in Guizhou Province and its surrounding areas, covering 1,582 sand and gravel mining rights.