Basalt, renowned for its exceptional hardness, is an indispensable raw material in numerous industrial sectors. However, its high hardness also necessitates careful processing to maximize its effectiveness. Among various crushing equipment, the C6X jaw

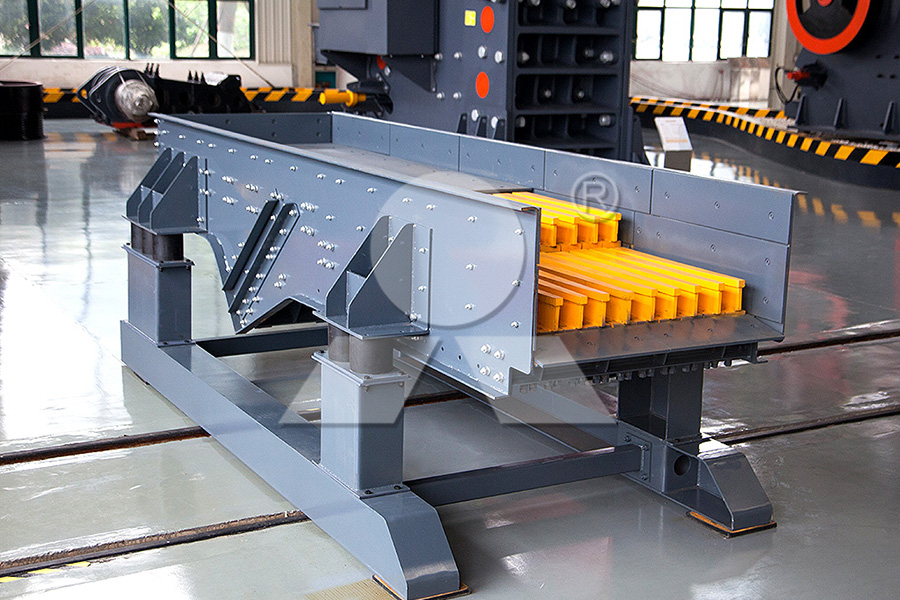

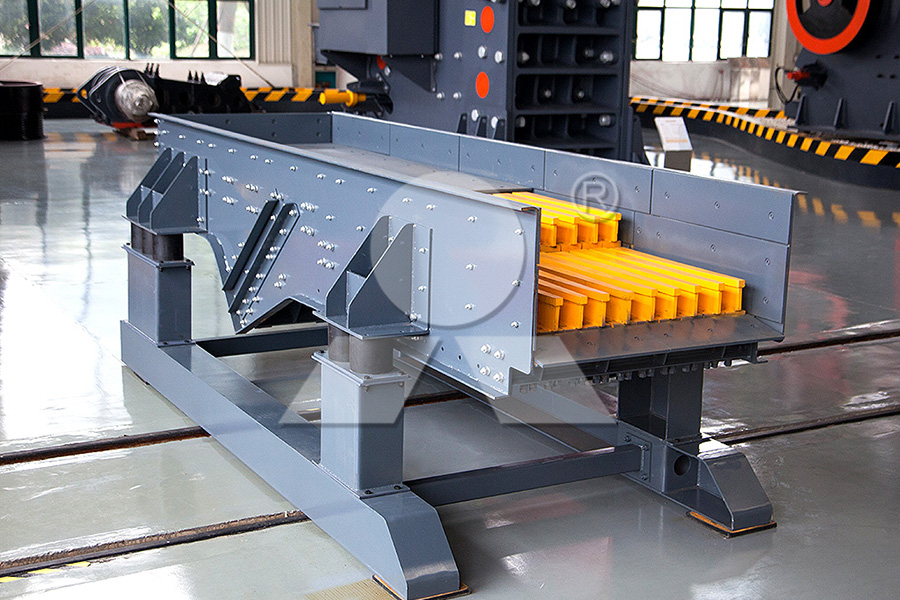

Basalt, renowned for its exceptional hardness, is an indispensable raw material in numerous industrial sectors. However, its high hardness also necessitates careful processing to maximize its effectiveness. Among various crushing equipment, the C6X jaw crusher stands out as an ideal choice for processing basalt due to its unique advantages, not only promoting efficient resource utilization but also significantly reducing waste.

More Advantages of Crushing Equipment

I. Crushing Performance, High-Efficiency Output

The C6X jaw crusher, a leader in coarse crushing, distinguishes itself with its deep crushing chamber and excellent crushing ratio. Within the same operating time, this equipment can crush basalt to the required particle size faster and more thoroughly, significantly increasing throughput and helping customers achieve high-efficiency output and maximize economic benefits.

II. Cost Optimization, Enhanced Efficiency

While pursuing high efficiency, the C6X jaw crusher also prioritizes cost control. Its streamlined yet highly efficient design ensures a smooth and rapid crushing process, reducing unnecessary energy consumption. Furthermore, the equipment utilizes high-quality wear-resistant materials, effectively reducing the replacement frequency of vulnerable parts and extending its service life. This reduces customer maintenance costs and overall operating expenses, saving businesses every penny and achieving a win-win situation in terms of cost-effectiveness.

III. Green and Environmentally Friendly

With increasing environmental awareness, the C6X jaw crusher actively responds to the call of the times, integrating green and environmentally friendly concepts into every detail. The built-in high-efficiency dust removal system and noise reduction device effectively suppress dust and noise pollution during crushing operations, creating a cleaner and quieter working environment for workers. This initiative not only reflects the company's social responsibility but also contributes to promoting the green and sustainable development of the industry.

In conclusion, the C6X jaw crusher, with its high-efficiency crushing capacity, optimized cost structure, and excellent environmental performance, demonstrates strong competitiveness in the basalt processing field. Choosing the C6X jaw crusher means choosing higher production efficiency, lower operating costs, and a greener production model. Of course, to ensure high production results, proper model selection is equally crucial. Different models of the C6X jaw crusher each have their own characteristics, precisely matching customer needs and jointly promoting the transformation and upgrading of the basalt processing industry.

Previous: SMP Crusher

Next: SMP Crusher

Basalt, renowned for its exceptional hardness, is an indispensable raw material in numerous industrial sectors. However, its high hardness also necessitates careful processing to maximize its effectiveness. Among various crushing equipment, the C6X jaw

Basalt, renowned for its exceptional hardness, is an indispensable raw material in numerous industrial sectors. However, its high hardness also necessitates careful processing to maximize its effectiveness. Among various crushing equipment, the C6X jaw crusher stands out as an ideal choice for processing basalt due to its unique advantages, not only promoting efficient resource utilization but also significantly reducing waste.

More Advantages of Crushing Equipment

I. Crushing Performance, High-Efficiency Output

The C6X jaw crusher, a leader in coarse crushing, distinguishes itself with its deep crushing chamber and excellent crushing ratio. Within the same operating time, this equipment can crush basalt to the required particle size faster and more thoroughly, significantly increasing throughput and helping customers achieve high-efficiency output and maximize economic benefits.

II. Cost Optimization, Enhanced Efficiency

While pursuing high efficiency, the C6X jaw crusher also prioritizes cost control. Its streamlined yet highly efficient design ensures a smooth and rapid crushing process, reducing unnecessary energy consumption. Furthermore, the equipment utilizes high-quality wear-resistant materials, effectively reducing the replacement frequency of vulnerable parts and extending its service life. This reduces customer maintenance costs and overall operating expenses, saving businesses every penny and achieving a win-win situation in terms of cost-effectiveness.

III. Green and Environmentally Friendly

With increasing environmental awareness, the C6X jaw crusher actively responds to the call of the times, integrating green and environmentally friendly concepts into every detail. The built-in high-efficiency dust removal system and noise reduction device effectively suppress dust and noise pollution during crushing operations, creating a cleaner and quieter working environment for workers. This initiative not only reflects the company's social responsibility but also contributes to promoting the green and sustainable development of the industry.

In conclusion, the C6X jaw crusher, with its high-efficiency crushing capacity, optimized cost structure, and excellent environmental performance, demonstrates strong competitiveness in the basalt processing field. Choosing the C6X jaw crusher means choosing higher production efficiency, lower operating costs, and a greener production model. Of course, to ensure high production results, proper model selection is equally crucial. Different models of the C6X jaw crusher each have their own characteristics, precisely matching customer needs and jointly promoting the transformation and upgrading of the basalt processing industry.

Previous: SMP Crusher

Next: SMP Crusher

Configuration of a silicon ore crushing and processing production line

Configuration of a silicon ore crushing and processing production line Gansu Longnan Shibang 500-ton-per-hour limestone crushing and sand making project

Gansu Longnan Shibang 500-ton-per-hour limestone crushing and sand making project What types of sand making machines have a capacity of 100 tons per hour? How much does one cost?

What types of sand making machines have a capacity of 100 tons per hour? How much does one cost? Comparison of differences between different cone crushers

Comparison of differences between different cone crushers Shibang Gansu Lanzhou 500-ton-per-hour tuff crushing and sand making project

Shibang Gansu Lanzhou 500-ton-per-hour tuff crushing and sand making project Configuration of a silicon ore crushing and processing production line

Configuration of a silicon ore crushing and processing production line Gansu Longnan Shibang 500-ton-per-hour limestone crushing and sand making project

Gansu Longnan Shibang 500-ton-per-hour limestone crushing and sand making project What types of sand making machines have a capacity of 100 tons per hour? How much does one cost?

What types of sand making machines have a capacity of 100 tons per hour? How much does one cost? Comparison of differences between different cone crushers

Comparison of differences between different cone crushers Shibang Gansu Lanzhou 500-ton-per-hour tuff crushing and sand making project

Shibang Gansu Lanzhou 500-ton-per-hour tuff crushing and sand making project