With the rapid development of mining equipment, a lot of new mill equipment emerging, which Clerik production of ultra-fine mill by the majority of customers welcome, ultra-fine mill is welcomed by the majority of users because it has six major p

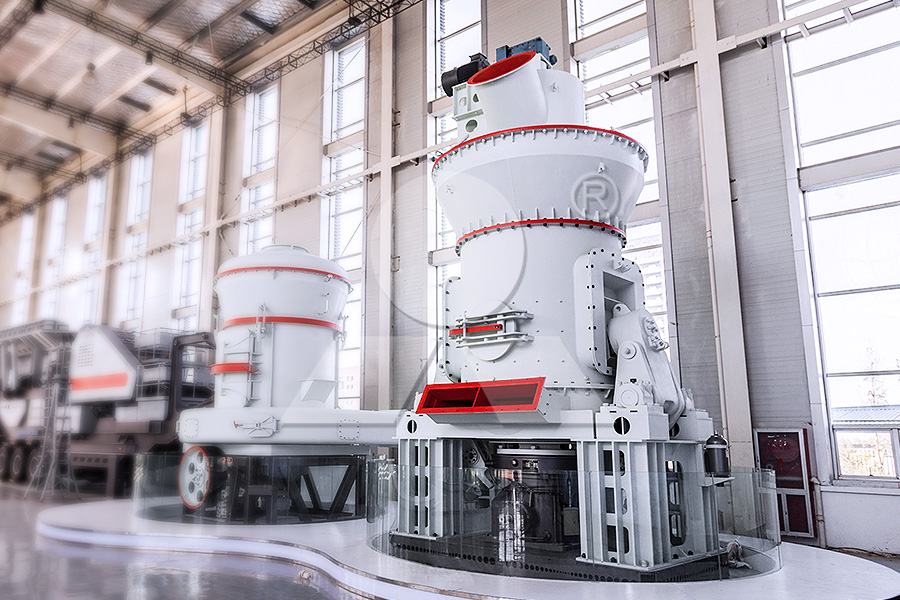

With the rapid development of mining equipment, a lot of new mill equipment emerging, which Clerik production of ultra-fine mill by the majority of customers welcome, ultra-fine mill is welcomed by the majority of users because it has six major performance characteristics.

1, high efficiency and low consumption;

2, long service life of wearing parts;

3, high safety and reliability;

4, high product fineness;

5, environmental cleanliness;

6, advanced only frequency conversion speed control device.

The big feature of the ultra-fine mill is to win the fineness, then in the process of using some external and internal factors will affect the fineness of the mill, which is also the new and old customers are very concerned about Clirik, today I summarize a few of the impact of ultra-fine mill grinding fineness of the reasons for everyone:

1, the grinding material is different, the purity is different, such as grinding artificial graphite powder, its purity than grinding petroleum coke or asphalt coke when the purity to be lower, slightly coarser particle size.

2, the impact of feed size: feed particle size is small, the purity is higher.

3, the influence of feeding material:

1) Too much feed, the damper is easy to block, low output, fine particle size. The solution is to suspend the Raymond mill feed or stop the machine to pick out some material to produce again; or reduce or close the remaining air duct valve;

2) If the feed is sufficient, the wind volume is large, the purity of grinding becomes low, the particle size becomes coarse. Can increase the feed, or open the remaining wind pipe valve.

4, the impact of the size of the wind:

The air volume is large, the particle size becomes coarse, the air volume is small, the particle size becomes fine.

SMPCRUSHER is a high-tech company integrating R&D, production and distribution, and provides crusher, sand making, grinding equipment, mobile crushing station, etc. mature products and solutions used in aggregate, mining and waste recycling. At present, we have established cooperative relations with customers in more than 170 countries, and helped them plan reasonable programme and realize scientific process.

Previous: SMP Crusher

Next: SMP Crusher

With the rapid development of mining equipment, a lot of new mill equipment emerging, which Clerik production of ultra-fine mill by the majority of customers welcome, ultra-fine mill is welcomed by the majority of users because it has six major p

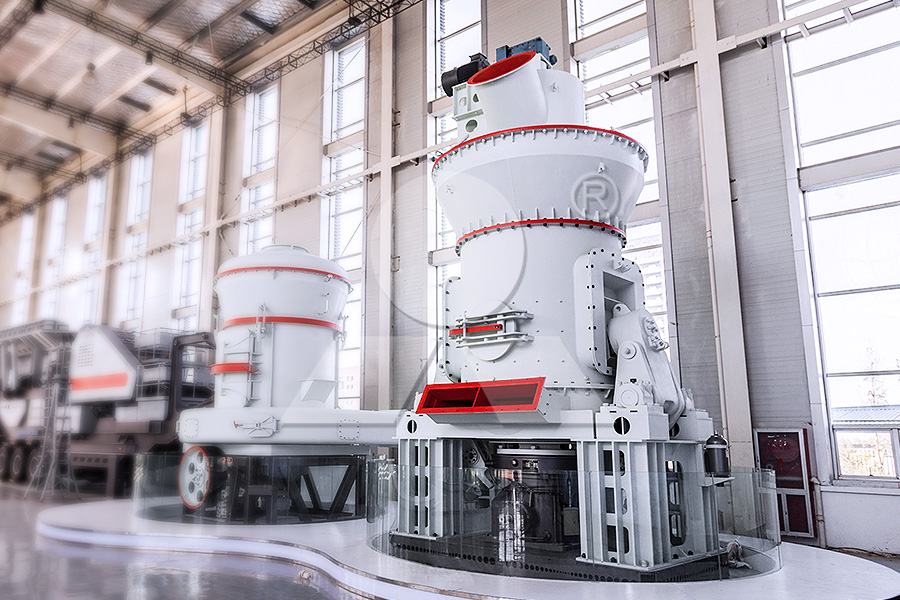

With the rapid development of mining equipment, a lot of new mill equipment emerging, which Clerik production of ultra-fine mill by the majority of customers welcome, ultra-fine mill is welcomed by the majority of users because it has six major performance characteristics.

1, high efficiency and low consumption;

2, long service life of wearing parts;

3, high safety and reliability;

4, high product fineness;

5, environmental cleanliness;

6, advanced only frequency conversion speed control device.

The big feature of the ultra-fine mill is to win the fineness, then in the process of using some external and internal factors will affect the fineness of the mill, which is also the new and old customers are very concerned about Clirik, today I summarize a few of the impact of ultra-fine mill grinding fineness of the reasons for everyone:

1, the grinding material is different, the purity is different, such as grinding artificial graphite powder, its purity than grinding petroleum coke or asphalt coke when the purity to be lower, slightly coarser particle size.

2, the impact of feed size: feed particle size is small, the purity is higher.

3, the influence of feeding material:

1) Too much feed, the damper is easy to block, low output, fine particle size. The solution is to suspend the Raymond mill feed or stop the machine to pick out some material to produce again; or reduce or close the remaining air duct valve;

2) If the feed is sufficient, the wind volume is large, the purity of grinding becomes low, the particle size becomes coarse. Can increase the feed, or open the remaining wind pipe valve.

4, the impact of the size of the wind:

The air volume is large, the particle size becomes coarse, the air volume is small, the particle size becomes fine.

SMPCRUSHER is a high-tech company integrating R&D, production and distribution, and provides crusher, sand making, grinding equipment, mobile crushing station, etc. mature products and solutions used in aggregate, mining and waste recycling. At present, we have established cooperative relations with customers in more than 170 countries, and helped them plan reasonable programme and realize scientific process.

Previous: SMP Crusher

Next: SMP Crusher

Hardness and Mohs hardness requirements of minerals for grinding ores in mills

Hardness and Mohs hardness requirements of minerals for grinding ores in mills How to adjust the fineness and output of grinding mill

How to adjust the fineness and output of grinding mill Voltage instability will bring what effect to the raymond mill

Voltage instability will bring what effect to the raymond mill According to the hardness of the material to choose their own Raymond mill equipment

According to the hardness of the material to choose their own Raymond mill equipment How the limestone grinding mill is dust treatment

How the limestone grinding mill is dust treatment Hardness and Mohs hardness requirements of minerals for grinding ores in mills

Hardness and Mohs hardness requirements of minerals for grinding ores in mills How to adjust the fineness and output of grinding mill

How to adjust the fineness and output of grinding mill Voltage instability will bring what effect to the raymond mill

Voltage instability will bring what effect to the raymond mill According to the hardness of the material to choose their own Raymond mill equipment

According to the hardness of the material to choose their own Raymond mill equipment How the limestone grinding mill is dust treatment

How the limestone grinding mill is dust treatment