Industrial crushers are widely used in sand and gravel plants, primarily for crushing granite, coal gangue, limestone, river pebbles, and other stones. With the continuous growth of market demand, the types and models of crushers are becoming increasin

Industrial crushers are widely used in sand and gravel plants, primarily for crushing granite, coal gangue, limestone, river pebbles, and other stones. With the continuous growth of market demand, the types and models of crushers are becoming increasingly diverse, covering a wide range of equipment from small to large and intelligent. This article will introduce several common industrial crushers, their prices, and complete equipment configuration schemes.

Specific Industrial Crusher Equipment Prices

1. Coarse Crushing of Stone – Jaw Crusher

Jaw crushers are commonly used coarse crushing equipment in sand making and stone crushing, and are a classic choice in the mining industry. Their main function is to crush large stones (≤1.5 meters) into medium or small pieces, preparing them for subsequent processing. Jaw crushers are characterized by simple structure, economical price, and easy maintenance. Their capacity ranges from 1 to 1000 tons/hour, and their price ranges from 200,000 to 1,000,000 yuan.

2. Medium Crushing of Stone – Impact Crusher and Cone Crusher

Impact Crusher: Suitable for medium crushing of brittle materials with low hardness. Relatively inexpensive, producing excellent aggregate shape and high-value finished products.

Cone Crusher: Used for medium crushing of harder stones. Employs a layered crushing principle, producing uniform particle shape and size. High crushing efficiency and adjustable discharge size.

The price of impact crushers and cone crushers generally ranges from 300,000 to 800,000 RMB.

3. Fine Crushing of Stone – Impact Crusher and Hydraulic Opening Sand Making Machine

Stones after coarse and medium crushing need to be processed by fine crushing equipment.

Impact Crusher: Suitable for high-output needs. A new type of sand making machine with a high degree of automation. Priced between 500,000 and 1,000,000 RMB.

Hydraulic Opening Sand Making Machine: Suitable for small and medium-sized sand and gravel plants. Moderate output, producing high-quality finished particles. High cost-effectiveness. Priced between 200,000 and 500,000 RMB.

Shibang Group

Crushing/Sand Making/Grinding Consulting

Call Now

Complete Equipment Configuration Solutions

Common sand and gravel production lines typically consist of the above-mentioned equipment, offering high production efficiency and stable operation. Below are two typical complete equipment configuration solutions.

I. Fixed Crusher Complete Equipment

Coarse Crushing Equipment: Jaw Crusher, simple to install, large feed opening, suitable for various coarse crushing needs.

Medium Crushing Equipment: Cone Crusher, mainly single-cylinder cone crushers, equipped with intelligent and remote operation functions, suitable for crushing high-hardness stone.

Fine Crushing Equipment: Includes single-cylinder cone crushers and hammer crushers. The latter can achieve coarse, medium, and fine crushing functions, and can also shape gravel, improving the quality of the finished product.

II. Mobile Crusher Complete Equipment

Mobile crusher complete equipment consists of a mobile crusher, equipped with various types of production equipment. Jaw crushers and hammer crushers can be mounted on a mobile frame (wheeled or tracked), facilitating on-site operation and transition.

Mobile Hammer Crusher: Mounted on a mobile frame with tires for easy operation and transitions.

Tracked Cone Crusher: Mounted on a tracked mobile crusher, offering high mobility and adaptability suitable for various terrains.

Price Reference and Purchase Recommendations: The price of complete industrial crushing equipment varies depending on configuration, model, and manufacturer. Generally, small crushers cost between 200,000 and 300,000 RMB, medium-sized equipment around 500,000 RMB, while high-end, large-scale, intelligent equipment can cost over 1 million RMB.

When purchasing complete industrial crushing equipment, it is recommended to choose equipment from large manufacturers, ensuring quality and fair pricing. Furthermore, readily available complete sets of equipment can better meet the needs of urgent projects, ensuring smooth production.

Through the above introduction, we hope to help you understand the types, prices, and complete equipment configurations of industrial crushers, allowing you to select suitable equipment for your production line and improve production efficiency and product quality.

Previous: SMP Crusher

Next: SMP Crusher

Industrial crushers are widely used in sand and gravel plants, primarily for crushing granite, coal gangue, limestone, river pebbles, and other stones. With the continuous growth of market demand, the types and models of crushers are becoming increasin

Industrial crushers are widely used in sand and gravel plants, primarily for crushing granite, coal gangue, limestone, river pebbles, and other stones. With the continuous growth of market demand, the types and models of crushers are becoming increasingly diverse, covering a wide range of equipment from small to large and intelligent. This article will introduce several common industrial crushers, their prices, and complete equipment configuration schemes.

Specific Industrial Crusher Equipment Prices

1. Coarse Crushing of Stone – Jaw Crusher

Jaw crushers are commonly used coarse crushing equipment in sand making and stone crushing, and are a classic choice in the mining industry. Their main function is to crush large stones (≤1.5 meters) into medium or small pieces, preparing them for subsequent processing. Jaw crushers are characterized by simple structure, economical price, and easy maintenance. Their capacity ranges from 1 to 1000 tons/hour, and their price ranges from 200,000 to 1,000,000 yuan.

2. Medium Crushing of Stone – Impact Crusher and Cone Crusher

Impact Crusher: Suitable for medium crushing of brittle materials with low hardness. Relatively inexpensive, producing excellent aggregate shape and high-value finished products.

Cone Crusher: Used for medium crushing of harder stones. Employs a layered crushing principle, producing uniform particle shape and size. High crushing efficiency and adjustable discharge size.

The price of impact crushers and cone crushers generally ranges from 300,000 to 800,000 RMB.

3. Fine Crushing of Stone – Impact Crusher and Hydraulic Opening Sand Making Machine

Stones after coarse and medium crushing need to be processed by fine crushing equipment.

Impact Crusher: Suitable for high-output needs. A new type of sand making machine with a high degree of automation. Priced between 500,000 and 1,000,000 RMB.

Hydraulic Opening Sand Making Machine: Suitable for small and medium-sized sand and gravel plants. Moderate output, producing high-quality finished particles. High cost-effectiveness. Priced between 200,000 and 500,000 RMB.

Shibang Group

Crushing/Sand Making/Grinding Consulting

Call Now

Complete Equipment Configuration Solutions

Common sand and gravel production lines typically consist of the above-mentioned equipment, offering high production efficiency and stable operation. Below are two typical complete equipment configuration solutions.

I. Fixed Crusher Complete Equipment

Coarse Crushing Equipment: Jaw Crusher, simple to install, large feed opening, suitable for various coarse crushing needs.

Medium Crushing Equipment: Cone Crusher, mainly single-cylinder cone crushers, equipped with intelligent and remote operation functions, suitable for crushing high-hardness stone.

Fine Crushing Equipment: Includes single-cylinder cone crushers and hammer crushers. The latter can achieve coarse, medium, and fine crushing functions, and can also shape gravel, improving the quality of the finished product.

II. Mobile Crusher Complete Equipment

Mobile crusher complete equipment consists of a mobile crusher, equipped with various types of production equipment. Jaw crushers and hammer crushers can be mounted on a mobile frame (wheeled or tracked), facilitating on-site operation and transition.

Mobile Hammer Crusher: Mounted on a mobile frame with tires for easy operation and transitions.

Tracked Cone Crusher: Mounted on a tracked mobile crusher, offering high mobility and adaptability suitable for various terrains.

Price Reference and Purchase Recommendations: The price of complete industrial crushing equipment varies depending on configuration, model, and manufacturer. Generally, small crushers cost between 200,000 and 300,000 RMB, medium-sized equipment around 500,000 RMB, while high-end, large-scale, intelligent equipment can cost over 1 million RMB.

When purchasing complete industrial crushing equipment, it is recommended to choose equipment from large manufacturers, ensuring quality and fair pricing. Furthermore, readily available complete sets of equipment can better meet the needs of urgent projects, ensuring smooth production.

Through the above introduction, we hope to help you understand the types, prices, and complete equipment configurations of industrial crushers, allowing you to select suitable equipment for your production line and improve production efficiency and product quality.

Previous: SMP Crusher

Next: SMP Crusher

Shibang Group upgrades 13.5 million-ton-per-year iron ore crushing production line at Nanfen Ore Beneficiation Plant

Shibang Group upgrades 13.5 million-ton-per-year iron ore crushing production line at Nanfen Ore Beneficiation Plant Which crusher manufacturer is the best?

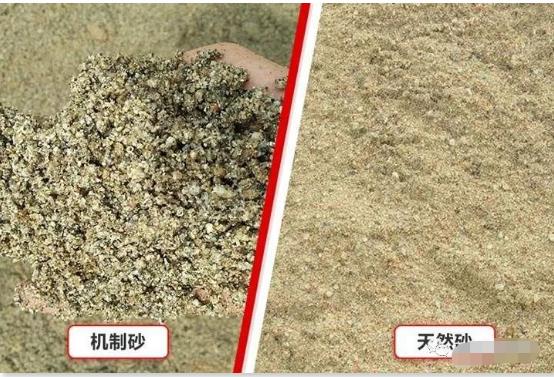

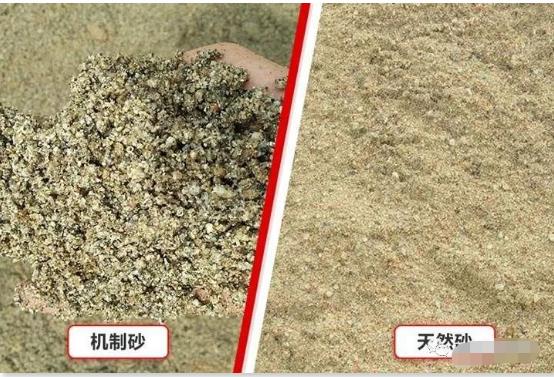

Which crusher manufacturer is the best? Process flow of manufactured sand production line

Process flow of manufactured sand production line How much does a mobile crusher cost?

How much does a mobile crusher cost? How much does a complete set of stone production equipment cost?

How much does a complete set of stone production equipment cost? Shibang Group upgrades 13.5 million-ton-per-year iron ore crushing production line at Nanfen Ore Beneficiation Plant

Shibang Group upgrades 13.5 million-ton-per-year iron ore crushing production line at Nanfen Ore Beneficiation Plant Which crusher manufacturer is the best?

Which crusher manufacturer is the best? Process flow of manufactured sand production line

Process flow of manufactured sand production line How much does a mobile crusher cost?

How much does a mobile crusher cost? How much does a complete set of stone production equipment cost?

How much does a complete set of stone production equipment cost?