Zhejiang Suichang cooperates with Shibang to build a 500-ton river dredging project to improve the water environmentThe 500-ton river dredging project implemented in Zhejiang Suichang aims to deepen the ecological concept of "Gr

Zhejiang Suichang cooperates with Shibang to build a 500-ton river dredging project to improve the water environment

The 500-ton river dredging project implemented in Zhejiang Suichang aims to deepen the ecological concept of "Green water and green mountains are gold and silver mountains", strengthen river management, optimize urban and rural water environment, and enhance the comprehensive benefits of rivers, lakes and reservoirs. In order to achieve the harmonious integration of green ecology and economic benefits, the customer carefully selected and finally cooperated with Shibang to customize the process design plan, purchase advanced crusher equipment, and enjoy professional installation services. This move not only reflects the importance of ecological protection, but also demonstrates the determination to achieve sustainable development.

Process link

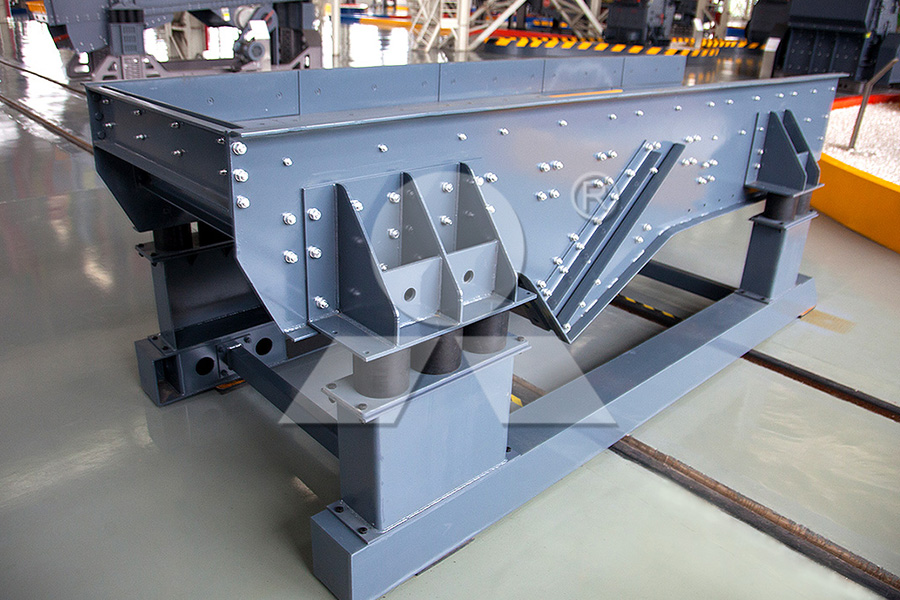

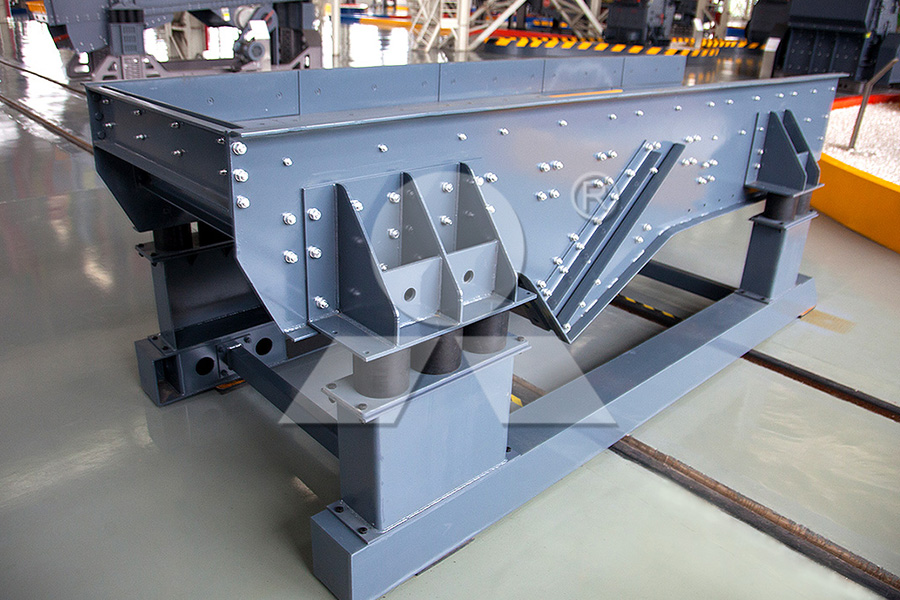

The raw materials are unloaded into the raw material warehouse by dump trucks. After pre-screening, the fine natural sand is stored in the sand workshop. The materials larger than 120mm are crushed in the jaw crusher for primary crushing, and then crushed by the single-cylinder hydraulic cone crusher to ensure the appropriate size of the materials.

After screening, materials larger than 31.5mm are returned to the multi-cylinder hydraulic cone crusher for cyclic crushing. After medium and fine crushing, 5-31.5mm materials are shaped and made into sand by the impact crusher, and then screened to obtain four types of finished materials: 0-5mm, 5-10mm, 10-20mm, and 20-31.5mm.

The sewage generated during the wet production process is uniformly sent to the sludge treatment workshop for purification, ensuring that the production process meets environmental protection standards while achieving resource recycling.

Previous: SMP Crusher

Next: SMP Crusher

Zhejiang Suichang cooperates with Shibang to build a 500-ton river dredging project to improve the water environmentThe 500-ton river dredging project implemented in Zhejiang Suichang aims to deepen the ecological concept of "Gr

Zhejiang Suichang cooperates with Shibang to build a 500-ton river dredging project to improve the water environment

The 500-ton river dredging project implemented in Zhejiang Suichang aims to deepen the ecological concept of "Green water and green mountains are gold and silver mountains", strengthen river management, optimize urban and rural water environment, and enhance the comprehensive benefits of rivers, lakes and reservoirs. In order to achieve the harmonious integration of green ecology and economic benefits, the customer carefully selected and finally cooperated with Shibang to customize the process design plan, purchase advanced crusher equipment, and enjoy professional installation services. This move not only reflects the importance of ecological protection, but also demonstrates the determination to achieve sustainable development.

Process link

The raw materials are unloaded into the raw material warehouse by dump trucks. After pre-screening, the fine natural sand is stored in the sand workshop. The materials larger than 120mm are crushed in the jaw crusher for primary crushing, and then crushed by the single-cylinder hydraulic cone crusher to ensure the appropriate size of the materials.

After screening, materials larger than 31.5mm are returned to the multi-cylinder hydraulic cone crusher for cyclic crushing. After medium and fine crushing, 5-31.5mm materials are shaped and made into sand by the impact crusher, and then screened to obtain four types of finished materials: 0-5mm, 5-10mm, 10-20mm, and 20-31.5mm.

The sewage generated during the wet production process is uniformly sent to the sludge treatment workshop for purification, ensuring that the production process meets environmental protection standards while achieving resource recycling.

Previous: SMP Crusher

Next: SMP Crusher

How to choose a mining crusher manufacturer

How to choose a mining crusher manufacturer Which equipment to choose for a 500 tons per hour sand and gravel production line

Which equipment to choose for a 500 tons per hour sand and gravel production line Cooperate to build a production line of building stone mine with an annual output of 3 million tons

Cooperate to build a production line of building stone mine with an annual output of 3 million tons Over 10 billion yuan sand and gravel project started

Over 10 billion yuan sand and gravel project started Coarse crushing equipment C6X jaw crusher helps efficient production

Coarse crushing equipment C6X jaw crusher helps efficient production How to choose a mining crusher manufacturer

How to choose a mining crusher manufacturer Which equipment to choose for a 500 tons per hour sand and gravel production line

Which equipment to choose for a 500 tons per hour sand and gravel production line Cooperate to build a production line of building stone mine with an annual output of 3 million tons

Cooperate to build a production line of building stone mine with an annual output of 3 million tons Over 10 billion yuan sand and gravel project started

Over 10 billion yuan sand and gravel project started Coarse crushing equipment C6X jaw crusher helps efficient production

Coarse crushing equipment C6X jaw crusher helps efficient production