Soft rock, like limestone, is a common raw material for sand production. So, how should a sand and gravel aggregate production line be designed for soft rock sand production?Click here to learn about sand and gravel aggregate product

Soft rock, like limestone, is a common raw material for sand production. So, how should a sand and gravel aggregate production line be designed for soft rock sand production?

Click here to learn about sand and gravel aggregate production line construction plans.

Sand and gravel aggregate

Primary crushing is typically performed using a jaw crusher or impact crusher, followed by conveyor belt conveyor to an impact crusher for secondary crushing. After vibratory screening, substandard material is returned for re-crushing, while qualified material is sent to the finished product bin. The design of a soft rock sand production line emphasizes environmental protection, and enclosed plant buildings are recommended to reduce dust and noise. Dry production requires dust removal to ensure clean air, while wet production requires a wastewater treatment system to ensure water quality. The overall process aims to achieve efficient sand production while strictly adhering to green production standards.

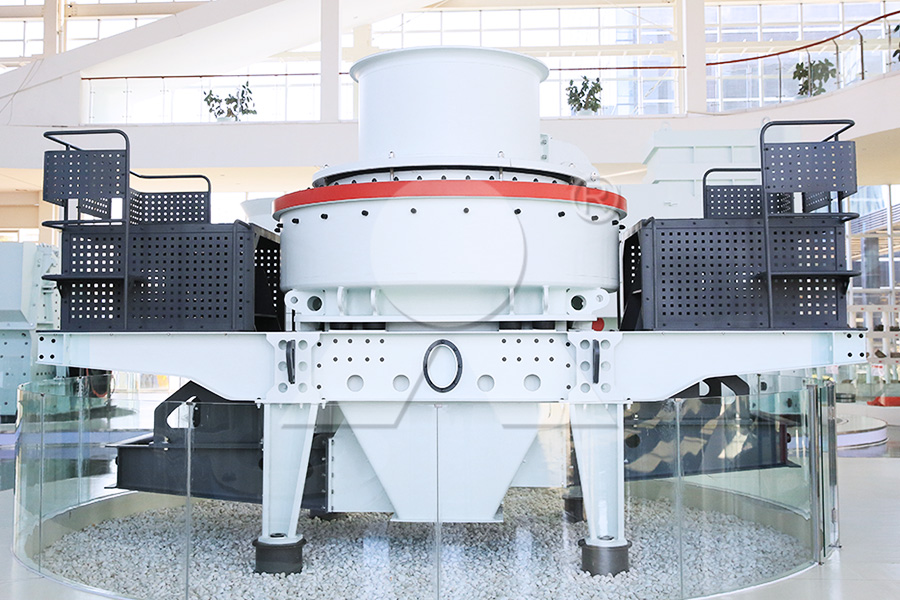

Impact crusher

While hard rock sand production is desirable, it's crucial to select the right equipment and process. How should a sand and gravel aggregate production line be designed for hard rock sand production?

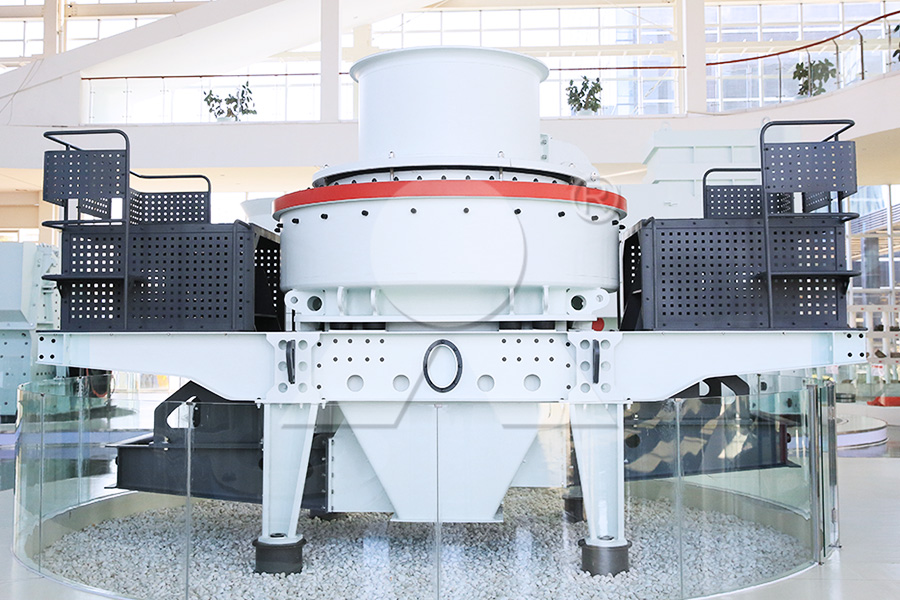

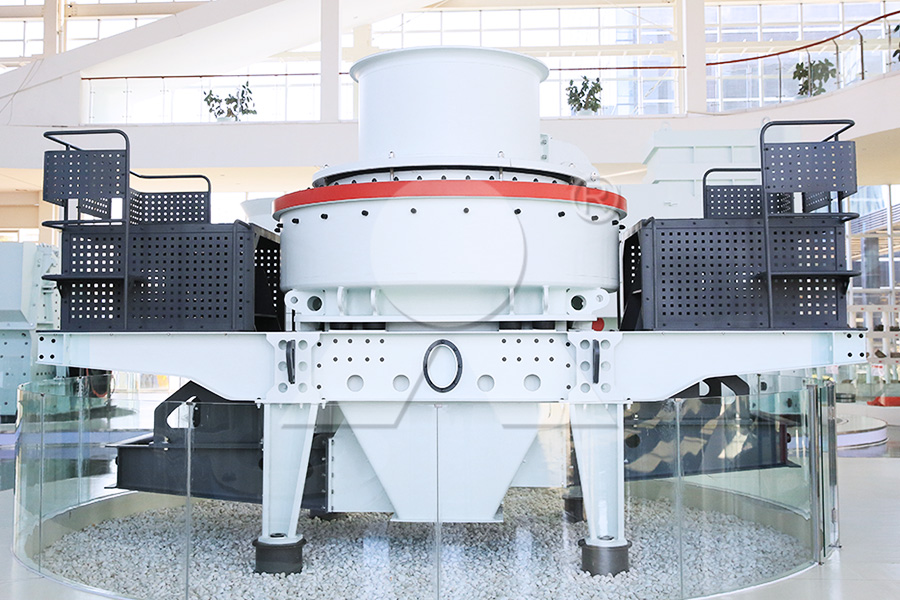

The sand production line

Hard rock sand production utilizes a three-stage crushing process. In the initial coarse crushing stage, a jaw or gyratory crusher is used, depending on the material's characteristics and needs. The material is then conveyed by belt conveyor to the secondary and tertiary crushing stage, where a hydraulic cone crusher, specifically designed for hard rock, is preferred for efficient crushing. After crushing, the material is screened and then processed to the desired particle size using a vertical shaft sand making machine. Finally, the machine-made sand that meets the standards is screened and stored in a finished product warehouse for use in projects. The entire production line design emphasizes environmental friendliness, minimizing dust, noise, and energy consumption at every stage, from crushing to finished product, to achieve sustainable development.

Previous: SMP Crusher

Next: SMP Crusher

Soft rock, like limestone, is a common raw material for sand production. So, how should a sand and gravel aggregate production line be designed for soft rock sand production?Click here to learn about sand and gravel aggregate product

Soft rock, like limestone, is a common raw material for sand production. So, how should a sand and gravel aggregate production line be designed for soft rock sand production?

Click here to learn about sand and gravel aggregate production line construction plans.

Sand and gravel aggregate

Primary crushing is typically performed using a jaw crusher or impact crusher, followed by conveyor belt conveyor to an impact crusher for secondary crushing. After vibratory screening, substandard material is returned for re-crushing, while qualified material is sent to the finished product bin. The design of a soft rock sand production line emphasizes environmental protection, and enclosed plant buildings are recommended to reduce dust and noise. Dry production requires dust removal to ensure clean air, while wet production requires a wastewater treatment system to ensure water quality. The overall process aims to achieve efficient sand production while strictly adhering to green production standards.

Impact crusher

While hard rock sand production is desirable, it's crucial to select the right equipment and process. How should a sand and gravel aggregate production line be designed for hard rock sand production?

The sand production line

Hard rock sand production utilizes a three-stage crushing process. In the initial coarse crushing stage, a jaw or gyratory crusher is used, depending on the material's characteristics and needs. The material is then conveyed by belt conveyor to the secondary and tertiary crushing stage, where a hydraulic cone crusher, specifically designed for hard rock, is preferred for efficient crushing. After crushing, the material is screened and then processed to the desired particle size using a vertical shaft sand making machine. Finally, the machine-made sand that meets the standards is screened and stored in a finished product warehouse for use in projects. The entire production line design emphasizes environmental friendliness, minimizing dust, noise, and energy consumption at every stage, from crushing to finished product, to achieve sustainable development.

Previous: SMP Crusher

Next: SMP Crusher

What kind of crushing equipment is better for processing basalt into machine-made sand?

What kind of crushing equipment is better for processing basalt into machine-made sand? What are the advantages of 300 tons per hour large cone crusher

What are the advantages of 300 tons per hour large cone crusher Process flow and configuration of 200 tons per hour stone crushing production line

Process flow and configuration of 200 tons per hour stone crushing production line What is the price of a concrete crushing and recycling machine? What are the advantages of a concrete crushing and recycling machine?

What is the price of a concrete crushing and recycling machine? What are the advantages of a concrete crushing and recycling machine? Price analysis of complete sets of stone processing equipment

Price analysis of complete sets of stone processing equipment What kind of crushing equipment is better for processing basalt into machine-made sand?

What kind of crushing equipment is better for processing basalt into machine-made sand? What are the advantages of 300 tons per hour large cone crusher

What are the advantages of 300 tons per hour large cone crusher Process flow and configuration of 200 tons per hour stone crushing production line

Process flow and configuration of 200 tons per hour stone crushing production line What is the price of a concrete crushing and recycling machine? What are the advantages of a concrete crushing and recycling machine?

What is the price of a concrete crushing and recycling machine? What are the advantages of a concrete crushing and recycling machine? Price analysis of complete sets of stone processing equipment

Price analysis of complete sets of stone processing equipment