Steel slag can be used as active cementing material to make sand, saving resources and improving the performance of building materials. The steel slag sand making line with an output of 100 tons per hour includes equipment such as vibrating feeding, ha

Steel slag can be used as active cementing material to make sand, saving resources and improving the performance of building materials. The steel slag sand making line with an output of 100 tons per hour includes equipment such as vibrating feeding, hammer crushing, vibrating screening, and hammer shaping. Steel slag sand making is environmentally friendly and economical. Shibang's new sand making machine is efficient, stable and widely used, helping customers create high benefits.

Steel slag is a solid waste generated during the steel production process. Because its chemical composition is similar to that of cement, it can be added to cement as an active cementitious material to improve the properties of cement. The resource utilization of steel slag not only saves a large amount of ore resources, but also significantly improves the performance of building materials. It can be said to kill two birds with one stone. So, how is sand made from steel slag? This article will introduce to you the design scheme and equipment configuration of a steel slag sand making production line with an output of 100 tons per hour.

Steel slag crushing and sand making production line

Advantages and equipment selection of steel slag sand making

Steel slag is brittle and brittle, so when used for sand making, the requirements for processing equipment are relatively low. The following steel slag sand making machines are common choices on the market:

Steel slag hammer sand making machine: It can break large pieces of steel slag into small particles at one time. It has the advantages of high crushing ratio, large output, solid structure and reliable performance, and is very suitable for primary crushing.

Steel slag impact sand making machine: In the secondary crushing, the discharge quality of the impact sand making machine is better than that of the hammer sand making machine. The finished particles are full, with few needles and flakes, and the material is durable, which helps to improve economic benefits.

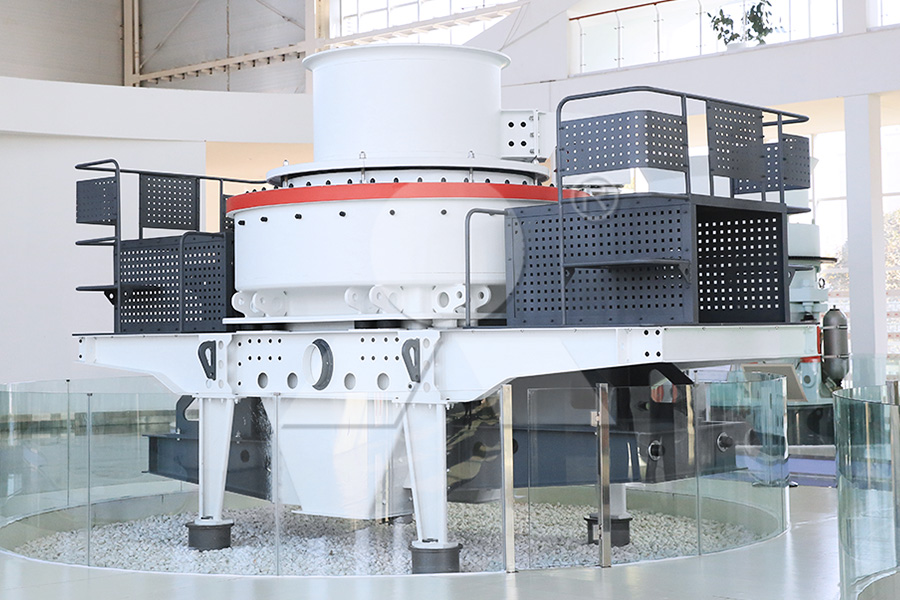

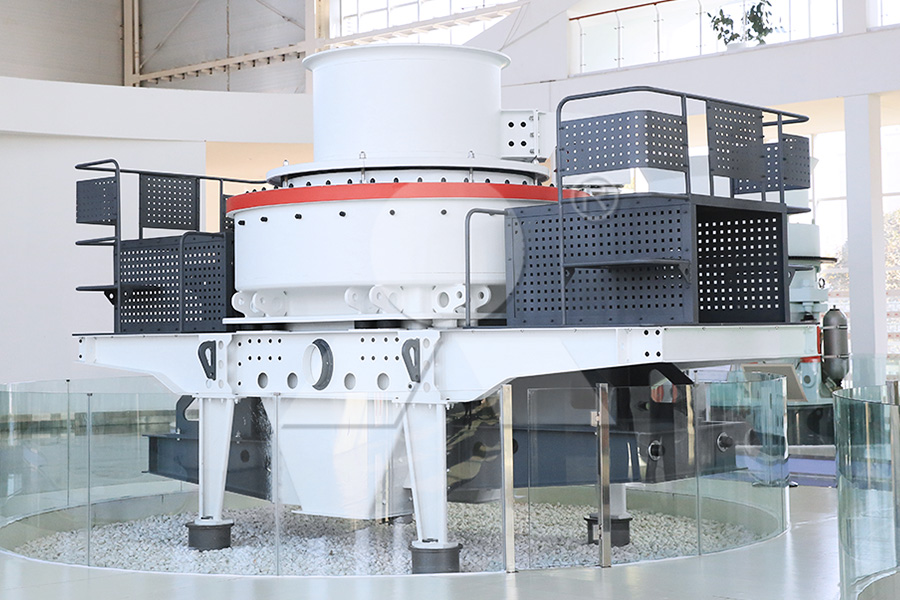

Steel slag fine crushing sand making machine: This equipment is used to make finished sand. The finished sand has reasonable gradation and large output. It is widely used in building concrete and other engineering construction fields.

Design plan of steel slag sand making production line with an output of 100 tons per hour

The steel slag sand making production line with an output of 100 tons per hour mainly includes vibrating feeder, hammer crusher, vibrating screen, hammer shaping crusher and other equipment. The specific equipment configuration is as follows:

Vibrating feeder: used to evenly transport steel slag to the crushing equipment.

Hammer crusher: Responsible for primary crushing, breaking large pieces of steel slag into smaller particles.

Vibrating screen: used to screen the crushed steel slag and separate the finished products that meet the particle size requirements.

Hammer shaping and crushing machine: further shaping and crushing the steel slag to ensure excellent grain shape of the finished product.

Economic and environmental benefits of steel slag sand making

With the gradual improvement of environmental protection policies, waste steel slag has become an important renewable resource with a wide range of applications after crushing. Steel slag can not only be used to produce cement, bricks, construction aggregates, etc., but can also effectively reduce land occupation by waste and eliminate environmental pollution.

Shibang's new steel slag sand making machine adopts advanced technology and is optimized for the characteristics of steel slag. It integrates three crushing modes and is the core equipment of the steel slag sand making industry. It has the characteristics of high wear resistance, long life, stable operation, and convenient operation. The treated steel slag performs well in road paving and asphalt concrete, helping to improve the durability of the road surface and reduce project costs.

As a leading crushing equipment manufacturer in the industry, Shibang Group can provide comprehensive equipment support for steel slag sand making production lines. Advanced equipment can not only process steel slag efficiently, but also ensure the stable quality of finished sand. It is widely used in various engineering constructions to create higher economic benefits for customers.

Previous: SMP Crusher

Next: SMP Crusher

Steel slag can be used as active cementing material to make sand, saving resources and improving the performance of building materials. The steel slag sand making line with an output of 100 tons per hour includes equipment such as vibrating feeding, ha

Steel slag can be used as active cementing material to make sand, saving resources and improving the performance of building materials. The steel slag sand making line with an output of 100 tons per hour includes equipment such as vibrating feeding, hammer crushing, vibrating screening, and hammer shaping. Steel slag sand making is environmentally friendly and economical. Shibang's new sand making machine is efficient, stable and widely used, helping customers create high benefits.

Steel slag is a solid waste generated during the steel production process. Because its chemical composition is similar to that of cement, it can be added to cement as an active cementitious material to improve the properties of cement. The resource utilization of steel slag not only saves a large amount of ore resources, but also significantly improves the performance of building materials. It can be said to kill two birds with one stone. So, how is sand made from steel slag? This article will introduce to you the design scheme and equipment configuration of a steel slag sand making production line with an output of 100 tons per hour.

Steel slag crushing and sand making production line

Advantages and equipment selection of steel slag sand making

Steel slag is brittle and brittle, so when used for sand making, the requirements for processing equipment are relatively low. The following steel slag sand making machines are common choices on the market:

Steel slag hammer sand making machine: It can break large pieces of steel slag into small particles at one time. It has the advantages of high crushing ratio, large output, solid structure and reliable performance, and is very suitable for primary crushing.

Steel slag impact sand making machine: In the secondary crushing, the discharge quality of the impact sand making machine is better than that of the hammer sand making machine. The finished particles are full, with few needles and flakes, and the material is durable, which helps to improve economic benefits.

Steel slag fine crushing sand making machine: This equipment is used to make finished sand. The finished sand has reasonable gradation and large output. It is widely used in building concrete and other engineering construction fields.

Design plan of steel slag sand making production line with an output of 100 tons per hour

The steel slag sand making production line with an output of 100 tons per hour mainly includes vibrating feeder, hammer crusher, vibrating screen, hammer shaping crusher and other equipment. The specific equipment configuration is as follows:

Vibrating feeder: used to evenly transport steel slag to the crushing equipment.

Hammer crusher: Responsible for primary crushing, breaking large pieces of steel slag into smaller particles.

Vibrating screen: used to screen the crushed steel slag and separate the finished products that meet the particle size requirements.

Hammer shaping and crushing machine: further shaping and crushing the steel slag to ensure excellent grain shape of the finished product.

Economic and environmental benefits of steel slag sand making

With the gradual improvement of environmental protection policies, waste steel slag has become an important renewable resource with a wide range of applications after crushing. Steel slag can not only be used to produce cement, bricks, construction aggregates, etc., but can also effectively reduce land occupation by waste and eliminate environmental pollution.

Shibang's new steel slag sand making machine adopts advanced technology and is optimized for the characteristics of steel slag. It integrates three crushing modes and is the core equipment of the steel slag sand making industry. It has the characteristics of high wear resistance, long life, stable operation, and convenient operation. The treated steel slag performs well in road paving and asphalt concrete, helping to improve the durability of the road surface and reduce project costs.

As a leading crushing equipment manufacturer in the industry, Shibang Group can provide comprehensive equipment support for steel slag sand making production lines. Advanced equipment can not only process steel slag efficiently, but also ensure the stable quality of finished sand. It is widely used in various engineering constructions to create higher economic benefits for customers.

Previous: SMP Crusher

Next: SMP Crusher

What are the machines for crushing stones into sand and how much do they cost?

What are the machines for crushing stones into sand and how much do they cost? What are the models of 100 tons per hour stone cone crusher? How much does one cost?

What are the models of 100 tons per hour stone cone crusher? How much does one cost? Equipment selection and production line configuration for crushing and processing bluestone

Equipment selection and production line configuration for crushing and processing bluestone How much does it cost to invest in a 3,000-ton-per-day gravel production line?

How much does it cost to invest in a 3,000-ton-per-day gravel production line? 1200 tons per hour gravel production line configuration

1200 tons per hour gravel production line configuration What are the machines for crushing stones into sand and how much do they cost?

What are the machines for crushing stones into sand and how much do they cost? What are the models of 100 tons per hour stone cone crusher? How much does one cost?

What are the models of 100 tons per hour stone cone crusher? How much does one cost? Equipment selection and production line configuration for crushing and processing bluestone

Equipment selection and production line configuration for crushing and processing bluestone How much does it cost to invest in a 3,000-ton-per-day gravel production line?

How much does it cost to invest in a 3,000-ton-per-day gravel production line? 1200 tons per hour gravel production line configuration

1200 tons per hour gravel production line configuration