Basalt is hard and resistant to compression, making it an ideal raw material for producing high-quality sand and gravel aggregates. As a key facility for processing basalt into sand and gravel for construction, the basalt sand and gravel production lin

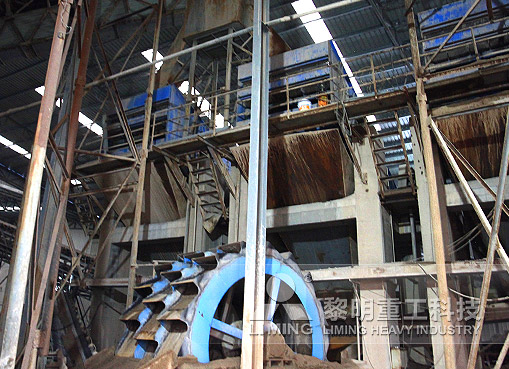

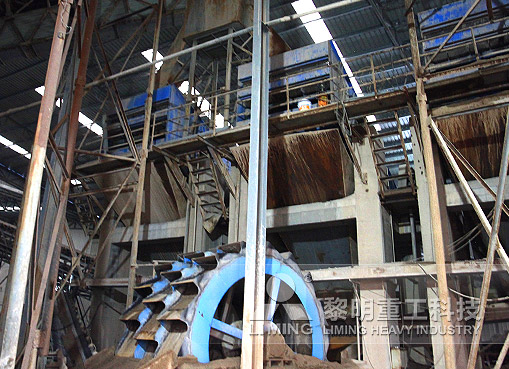

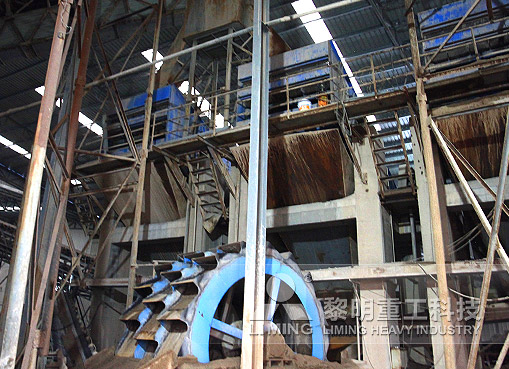

Basalt is hard and resistant to compression, making it an ideal raw material for producing high-quality sand and gravel aggregates. As a key facility for processing basalt into sand and gravel for construction, the basalt sand and gravel production line has attracted much attention for its process and equipment configuration.

The basalt sand and gravel production line generally consists of multiple links. The first is the coarse crushing stage, where the jaw crusher takes on the heavy responsibility. It has a simple structure and is easy to maintain. It can initially crush large pieces of basalt into smaller particles, providing raw materials of suitable particle size for subsequent processing. Then it enters the medium and fine crushing stage, where the cone crusher comes on stage. It adopts the principle of layered crushing, with high crushing strength, large processing capacity, low energy consumption, and uniform product particle size, which can further crush the coarsely crushed basalt.

After that is the sand making and shaping stage. The impact sand making machine uses the two crushing principles of "stone hitting stone" and "stone hitting iron" to make the finely crushed basalt into machine-made sand that meets the standards for construction sand. It not only has a large crushing ratio and a large processing capacity, but also has an adjustable output particle size. The finished products are mostly cubic, with few needle-like shapes and excellent quality.

In addition to these main equipment, auxiliary equipment such as feeders and vibrating screens are also indispensable. The feeder can evenly feed the basalt raw materials into the crushing chamber of the crusher to ensure the continuity and stability of the crushing process. The vibrating screen screens the crushed stones, screens out the stones that do not meet the particle size requirements and crushes them again, and the qualified stones are sent to the finished product area by the belt conveyor.

In actual applications, the equipment configuration of production lines of different sizes will be different. Small production lines may have fewer equipment and lower production capacity, while large production lines will be equipped with more and more advanced equipment, with a production capacity of thousands of tons per hour. Reasonable equipment selection and process configuration can give full play to the advantages of basalt, produce high-quality sand and gravel aggregates, and meet the needs of various infrastructure construction.

Previous: SMP Crusher

Next: SMP Crusher

Basalt is hard and resistant to compression, making it an ideal raw material for producing high-quality sand and gravel aggregates. As a key facility for processing basalt into sand and gravel for construction, the basalt sand and gravel production lin

Basalt is hard and resistant to compression, making it an ideal raw material for producing high-quality sand and gravel aggregates. As a key facility for processing basalt into sand and gravel for construction, the basalt sand and gravel production line has attracted much attention for its process and equipment configuration.

The basalt sand and gravel production line generally consists of multiple links. The first is the coarse crushing stage, where the jaw crusher takes on the heavy responsibility. It has a simple structure and is easy to maintain. It can initially crush large pieces of basalt into smaller particles, providing raw materials of suitable particle size for subsequent processing. Then it enters the medium and fine crushing stage, where the cone crusher comes on stage. It adopts the principle of layered crushing, with high crushing strength, large processing capacity, low energy consumption, and uniform product particle size, which can further crush the coarsely crushed basalt.

After that is the sand making and shaping stage. The impact sand making machine uses the two crushing principles of "stone hitting stone" and "stone hitting iron" to make the finely crushed basalt into machine-made sand that meets the standards for construction sand. It not only has a large crushing ratio and a large processing capacity, but also has an adjustable output particle size. The finished products are mostly cubic, with few needle-like shapes and excellent quality.

In addition to these main equipment, auxiliary equipment such as feeders and vibrating screens are also indispensable. The feeder can evenly feed the basalt raw materials into the crushing chamber of the crusher to ensure the continuity and stability of the crushing process. The vibrating screen screens the crushed stones, screens out the stones that do not meet the particle size requirements and crushes them again, and the qualified stones are sent to the finished product area by the belt conveyor.

In actual applications, the equipment configuration of production lines of different sizes will be different. Small production lines may have fewer equipment and lower production capacity, while large production lines will be equipped with more and more advanced equipment, with a production capacity of thousands of tons per hour. Reasonable equipment selection and process configuration can give full play to the advantages of basalt, produce high-quality sand and gravel aggregates, and meet the needs of various infrastructure construction.

Previous: SMP Crusher

Next: SMP Crusher

A detailed introduction to the overall picture of the basalt sand and gravel production line

A detailed introduction to the overall picture of the basalt sand and gravel production line The basalt stone production line produces nearly 10,000 tons per day, efficiently enabling infrastructure development

The basalt stone production line produces nearly 10,000 tons per day, efficiently enabling infrastructure development The impact of the ratio of basalt to river sand on the project

The impact of the ratio of basalt to river sand on the project 500 tons per hour granite crushing production line equipment unveiled

500 tons per hour granite crushing production line equipment unveiled The secrets of 500 tons per hour limestone crushing production line equipment

The secrets of 500 tons per hour limestone crushing production line equipment A detailed introduction to the overall picture of the basalt sand and gravel production line

A detailed introduction to the overall picture of the basalt sand and gravel production line The basalt stone production line produces nearly 10,000 tons per day, efficiently enabling infrastructure development

The basalt stone production line produces nearly 10,000 tons per day, efficiently enabling infrastructure development The impact of the ratio of basalt to river sand on the project

The impact of the ratio of basalt to river sand on the project 500 tons per hour granite crushing production line equipment unveiled

500 tons per hour granite crushing production line equipment unveiled The secrets of 500 tons per hour limestone crushing production line equipment

The secrets of 500 tons per hour limestone crushing production line equipment