In the field of infrastructure construction such as buildings and roads, gravel is a key raw material, and its quality and supply efficiency are crucial. However, traditional gravel production lines often face difficulties such as low production effici

In the field of infrastructure construction such as buildings and roads, gravel is a key raw material, and its quality and supply efficiency are crucial. However, traditional gravel production lines often face difficulties such as low production efficiency, high equipment failure rate, large fluctuations in product quality, and substandard environmental protection, which makes it difficult to meet the current rapidly developing market demand.

In response to these pain points, a series of effective optimization strategies have emerged. At the equipment level, new high-efficiency crushers, such as hydraulic crushers, are introduced, which have a higher crushing ratio and can reduce energy consumption by about 20%, greatly improving crushing efficiency. With intelligent screening equipment, it can accurately identify and separate gravel of different particle sizes, making screening more efficient. At the same time, equipping the crusher with a hydraulic iron release and cavity cleaning system can effectively reduce the downtime caused by foreign matter jamming and ensure production continuity. In the process link, a multi-stage crushing process is adopted, such as coarse crushing by a jaw crusher first, and then medium and fine crushing by a cone crusher to ensure uniform material particle size. Optimize the material transportation route, adopt a closed transportation channel to reduce dust generation; establish a waste recycling mechanism to improve resource utilization. In terms of management, we formulate strict equipment maintenance plans, regularly inspect equipment, and use intelligent monitoring technology to predict failures. We rationally divide employee positions, carry out regular technical and safety training, establish a scientific performance appraisal mechanism, and fully mobilize employee enthusiasm.

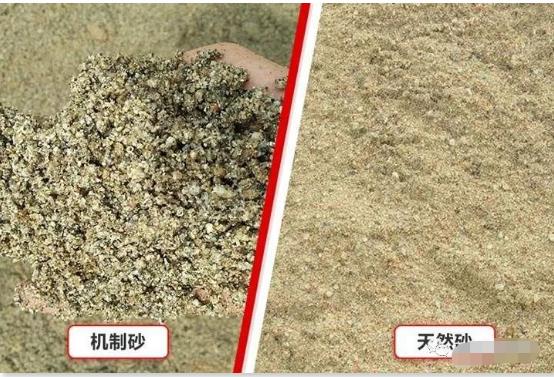

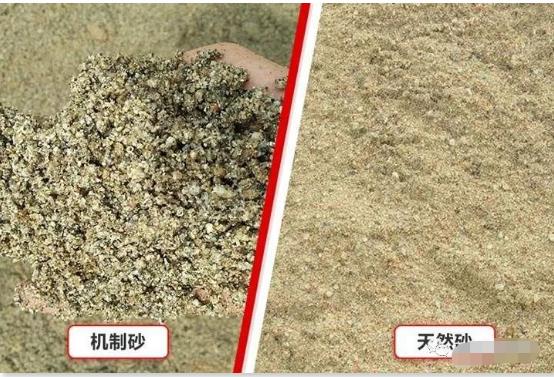

Many successful cases have witnessed the remarkable results after optimization. A high-standard gravel production line in Guizhou uses Shibang's full set of crushing and screening solutions. In the raw material pretreatment stage, the F5X1345 vibrating feeder is used to achieve uniform and stable feeding and pre-screening and soil removal to improve the purity of the raw materials. In the crushing stage, the PEW860 European hydraulic jaw crusher unit completes the first-level crushing, and two PFW1315Ⅲ impact crushers are connected in parallel for medium and fine crushing, and the S5X2760-2 vibrating screen is used for intelligent classification. The production line not only achieves 300-400 tons/hour of fine aggregate continuous output, but also reduces energy consumption by 15%-20% through PLC intelligent control, and the dust emission and noise indicators are better than national standards. The 1,200-ton-per-hour gravel production line of Jiangsu Xuzhou Mingyang Building Materials uses a heavy-duty hammer impact crusher and a complete crusher. The process is simple and efficient, which not only meets the processing needs of various specifications of stone, but also saves the cost of later installation and maintenance. A 600-ton-per-hour granite crushing production line in Fujian, through the reasonable configuration of f5x1660 feeder, c6x145 jaw crusher and other equipment, adopts wet processing technology, achieving a win-win situation of production capacity and environmental protection. Its finished gravel aggregates and machine-made sand accurately meet the diverse needs of different customers at home and abroad.

It can be seen that the optimization and upgrading of the gravel production line is of great significance to enhance the competitiveness of enterprises and promote the progress of the industry.

Previous: SMP Crusher

Next: SMP Crusher

In the field of infrastructure construction such as buildings and roads, gravel is a key raw material, and its quality and supply efficiency are crucial. However, traditional gravel production lines often face difficulties such as low production effici

In the field of infrastructure construction such as buildings and roads, gravel is a key raw material, and its quality and supply efficiency are crucial. However, traditional gravel production lines often face difficulties such as low production efficiency, high equipment failure rate, large fluctuations in product quality, and substandard environmental protection, which makes it difficult to meet the current rapidly developing market demand.

In response to these pain points, a series of effective optimization strategies have emerged. At the equipment level, new high-efficiency crushers, such as hydraulic crushers, are introduced, which have a higher crushing ratio and can reduce energy consumption by about 20%, greatly improving crushing efficiency. With intelligent screening equipment, it can accurately identify and separate gravel of different particle sizes, making screening more efficient. At the same time, equipping the crusher with a hydraulic iron release and cavity cleaning system can effectively reduce the downtime caused by foreign matter jamming and ensure production continuity. In the process link, a multi-stage crushing process is adopted, such as coarse crushing by a jaw crusher first, and then medium and fine crushing by a cone crusher to ensure uniform material particle size. Optimize the material transportation route, adopt a closed transportation channel to reduce dust generation; establish a waste recycling mechanism to improve resource utilization. In terms of management, we formulate strict equipment maintenance plans, regularly inspect equipment, and use intelligent monitoring technology to predict failures. We rationally divide employee positions, carry out regular technical and safety training, establish a scientific performance appraisal mechanism, and fully mobilize employee enthusiasm.

Many successful cases have witnessed the remarkable results after optimization. A high-standard gravel production line in Guizhou uses Shibang's full set of crushing and screening solutions. In the raw material pretreatment stage, the F5X1345 vibrating feeder is used to achieve uniform and stable feeding and pre-screening and soil removal to improve the purity of the raw materials. In the crushing stage, the PEW860 European hydraulic jaw crusher unit completes the first-level crushing, and two PFW1315Ⅲ impact crushers are connected in parallel for medium and fine crushing, and the S5X2760-2 vibrating screen is used for intelligent classification. The production line not only achieves 300-400 tons/hour of fine aggregate continuous output, but also reduces energy consumption by 15%-20% through PLC intelligent control, and the dust emission and noise indicators are better than national standards. The 1,200-ton-per-hour gravel production line of Jiangsu Xuzhou Mingyang Building Materials uses a heavy-duty hammer impact crusher and a complete crusher. The process is simple and efficient, which not only meets the processing needs of various specifications of stone, but also saves the cost of later installation and maintenance. A 600-ton-per-hour granite crushing production line in Fujian, through the reasonable configuration of f5x1660 feeder, c6x145 jaw crusher and other equipment, adopts wet processing technology, achieving a win-win situation of production capacity and environmental protection. Its finished gravel aggregates and machine-made sand accurately meet the diverse needs of different customers at home and abroad.

It can be seen that the optimization and upgrading of the gravel production line is of great significance to enhance the competitiveness of enterprises and promote the progress of the industry.

Previous: SMP Crusher

Next: SMP Crusher

Is it better to choose a single-cylinder or multi-cylinder cone crusher?

Is it better to choose a single-cylinder or multi-cylinder cone crusher? Guide to choosing and avoiding pitfalls in sand and gravel mining equipment: these details determine production efficiency

Guide to choosing and avoiding pitfalls in sand and gravel mining equipment: these details determine production efficiency How to choose the right core equipment for sand and gravel mines under the wave of intelligence

How to choose the right core equipment for sand and gravel mines under the wave of intelligence What crushers are suitable for mining waste rock and tailings?

What crushers are suitable for mining waste rock and tailings? How to choose the crusher for mine waste rock and tailings

How to choose the crusher for mine waste rock and tailings Is it better to choose a single-cylinder or multi-cylinder cone crusher?

Is it better to choose a single-cylinder or multi-cylinder cone crusher? Guide to choosing and avoiding pitfalls in sand and gravel mining equipment: these details determine production efficiency

Guide to choosing and avoiding pitfalls in sand and gravel mining equipment: these details determine production efficiency How to choose the right core equipment for sand and gravel mines under the wave of intelligence

How to choose the right core equipment for sand and gravel mines under the wave of intelligence What crushers are suitable for mining waste rock and tailings?

What crushers are suitable for mining waste rock and tailings? How to choose the crusher for mine waste rock and tailings

How to choose the crusher for mine waste rock and tailings