In the process of mining and comprehensive resource utilization, the treatment of waste rock and tailings has always been a key link. Reasonable selection of crushers can not only improve resource recovery efficiency, but also reduce the risk of enviro

In the process of mining and comprehensive resource utilization, the treatment of waste rock and tailings has always been a key link. Reasonable selection of crushers can not only improve resource recovery efficiency, but also reduce the risk of environmental pollution. So, which crushers are suitable for the crushing of mine waste rock and tailings?

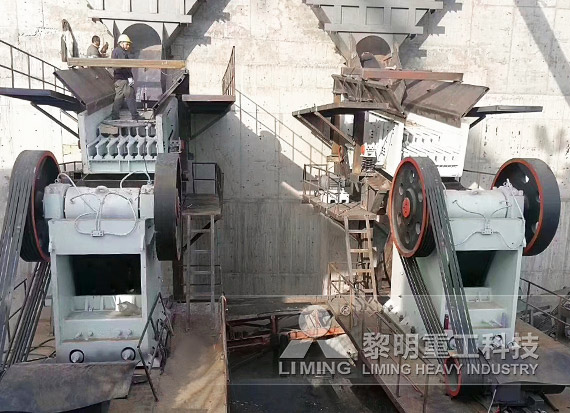

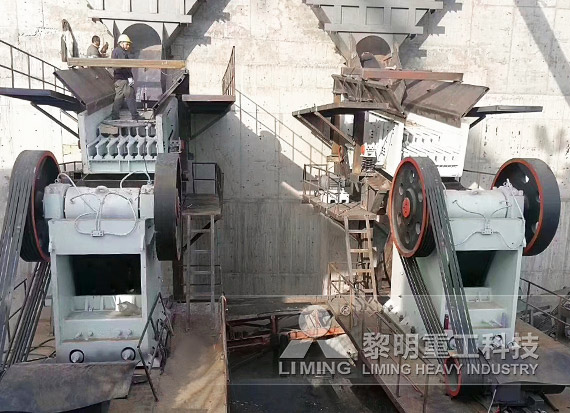

As the preferred equipment for primary crushing, the jaw crusher performs well in the treatment of mine waste rock and tailings. It has a simple structure and reliable operation. It can crush all kinds of waste rock and tailings with low compressive strength, with a large crushing ratio and uniform particle size, providing high-quality raw materials for subsequent processing.

The impact crusher is also suitable for such scenarios. It uses impact energy to crush materials. After crushing, the finished product is cubic, without tension and cracks, and has excellent particle shape. Whether it is waste rock with low hardness or tailings with high water content, the impact crusher can handle it efficiently, and the discharge particle size can be flexibly adjusted.

The cone crusher focuses on medium and fine crushing operations, especially for hard waste rock and tailings with medium hardness or above. It achieves efficient crushing through multiple squeezing and impacting of the moving cone and the fixed cone. It has strong crushing capacity, high operating efficiency, less consumption of wearing parts and low operating cost.

The mobile crusher integrates crushing, screening, conveying and other functions, and can be flexibly adjusted according to on-site needs. It is suitable for mobile operations, such as tailings pond management and waste rock field cleaning, and can quickly complete crushing tasks and improve resource utilization.

When choosing a crusher, it is necessary to comprehensively consider factors such as material characteristics, processing scale, and finished product requirements. Only by choosing a suitable crusher can efficient processing and resource utilization of mine waste rock and tailings be achieved.

Previous: SMP Crusher

Next: SMP Crusher

In the process of mining and comprehensive resource utilization, the treatment of waste rock and tailings has always been a key link. Reasonable selection of crushers can not only improve resource recovery efficiency, but also reduce the risk of enviro

In the process of mining and comprehensive resource utilization, the treatment of waste rock and tailings has always been a key link. Reasonable selection of crushers can not only improve resource recovery efficiency, but also reduce the risk of environmental pollution. So, which crushers are suitable for the crushing of mine waste rock and tailings?

As the preferred equipment for primary crushing, the jaw crusher performs well in the treatment of mine waste rock and tailings. It has a simple structure and reliable operation. It can crush all kinds of waste rock and tailings with low compressive strength, with a large crushing ratio and uniform particle size, providing high-quality raw materials for subsequent processing.

The impact crusher is also suitable for such scenarios. It uses impact energy to crush materials. After crushing, the finished product is cubic, without tension and cracks, and has excellent particle shape. Whether it is waste rock with low hardness or tailings with high water content, the impact crusher can handle it efficiently, and the discharge particle size can be flexibly adjusted.

The cone crusher focuses on medium and fine crushing operations, especially for hard waste rock and tailings with medium hardness or above. It achieves efficient crushing through multiple squeezing and impacting of the moving cone and the fixed cone. It has strong crushing capacity, high operating efficiency, less consumption of wearing parts and low operating cost.

The mobile crusher integrates crushing, screening, conveying and other functions, and can be flexibly adjusted according to on-site needs. It is suitable for mobile operations, such as tailings pond management and waste rock field cleaning, and can quickly complete crushing tasks and improve resource utilization.

When choosing a crusher, it is necessary to comprehensively consider factors such as material characteristics, processing scale, and finished product requirements. Only by choosing a suitable crusher can efficient processing and resource utilization of mine waste rock and tailings be achieved.

Previous: SMP Crusher

Next: SMP Crusher

Does the selection of crusher have anything to do with the size of the mine?

Does the selection of crusher have anything to do with the size of the mine? Does the brand of the crusher matter?

Does the brand of the crusher matter? Is the brand and price of the crusher proportional?

Is the brand and price of the crusher proportional? With an investment of 180 million yuan, Liming Heavy Industry enables Henan to build an environmentally friendly sand and gravel base with an annual output of 6.5 million tons

With an investment of 180 million yuan, Liming Heavy Industry enables Henan to build an environmentally friendly sand and gravel base with an annual output of 6.5 million tons With an investment of 230 million yuan, Liming Heavy Industry helps Jiangxi build an intelligent sand and gravel comprehensive park with an annual output of 8 million tons

With an investment of 230 million yuan, Liming Heavy Industry helps Jiangxi build an intelligent sand and gravel comprehensive park with an annual output of 8 million tons Does the selection of crusher have anything to do with the size of the mine?

Does the selection of crusher have anything to do with the size of the mine? Does the brand of the crusher matter?

Does the brand of the crusher matter? Is the brand and price of the crusher proportional?

Is the brand and price of the crusher proportional? With an investment of 180 million yuan, Liming Heavy Industry enables Henan to build an environmentally friendly sand and gravel base with an annual output of 6.5 million tons

With an investment of 180 million yuan, Liming Heavy Industry enables Henan to build an environmentally friendly sand and gravel base with an annual output of 6.5 million tons With an investment of 230 million yuan, Liming Heavy Industry helps Jiangxi build an intelligent sand and gravel comprehensive park with an annual output of 8 million tons

With an investment of 230 million yuan, Liming Heavy Industry helps Jiangxi build an intelligent sand and gravel comprehensive park with an annual output of 8 million tons