Phosphogypsum is a kind of solid waste produced during the production of wet process phosphoric acid. The reasonable utilization of phosphogypsum can reduce the waste of resources and realize the sustainable development of resources. The main component

Phosphogypsum is a kind of solid waste produced during the production of wet process phosphoric acid. The reasonable utilization of phosphogypsum can reduce the waste of resources and realize the sustainable development of resources. The main components of apatite include calcium sulfate dihydrate, phosphate ore, residual phosphoric acid, fluoride, acid insoluble matter, organic matter, etc.

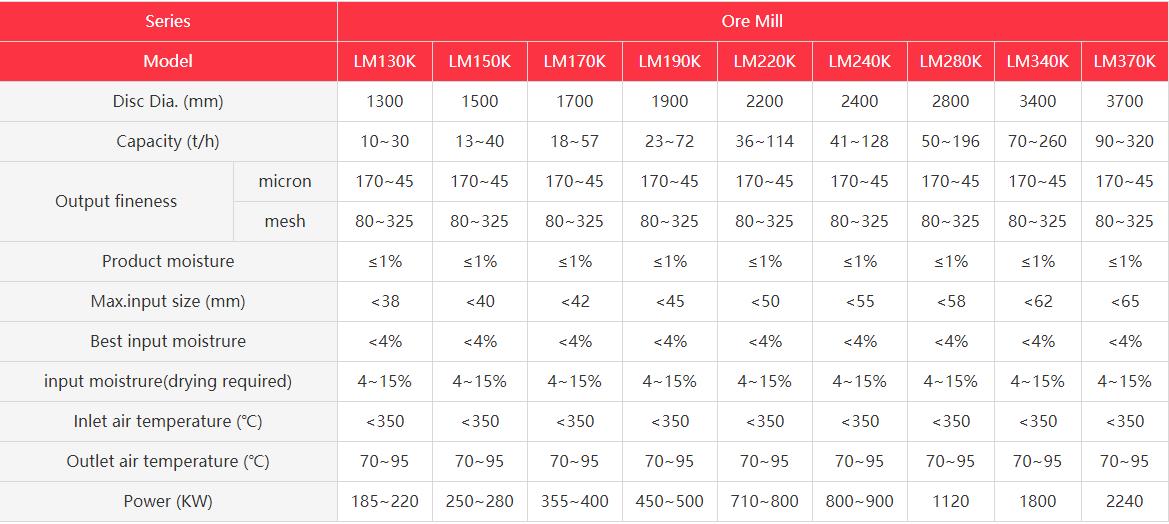

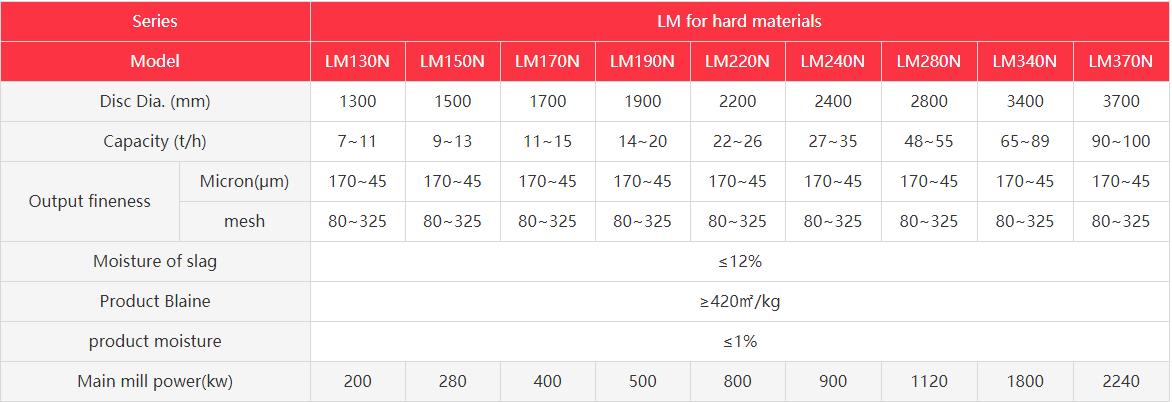

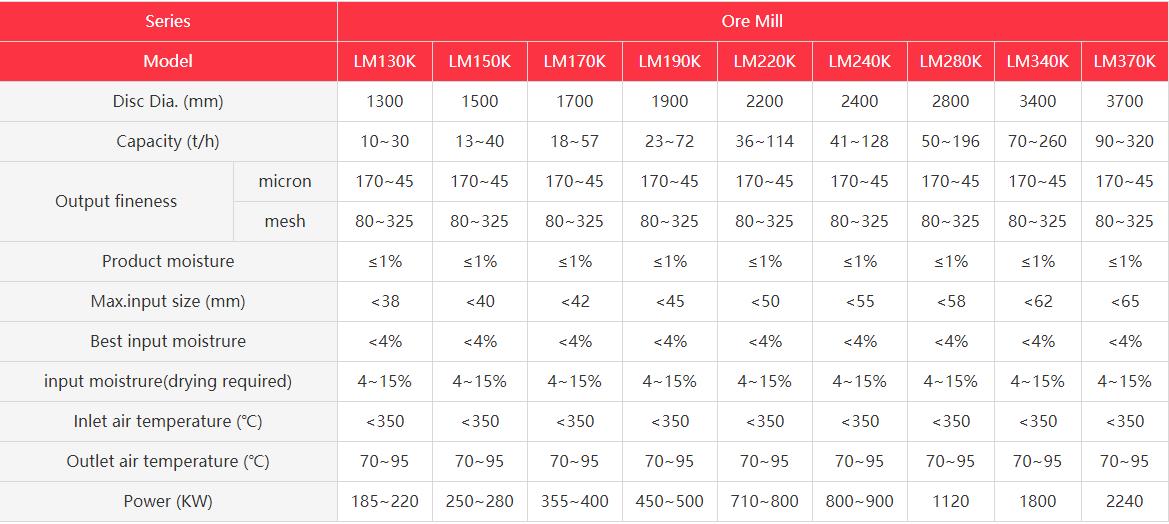

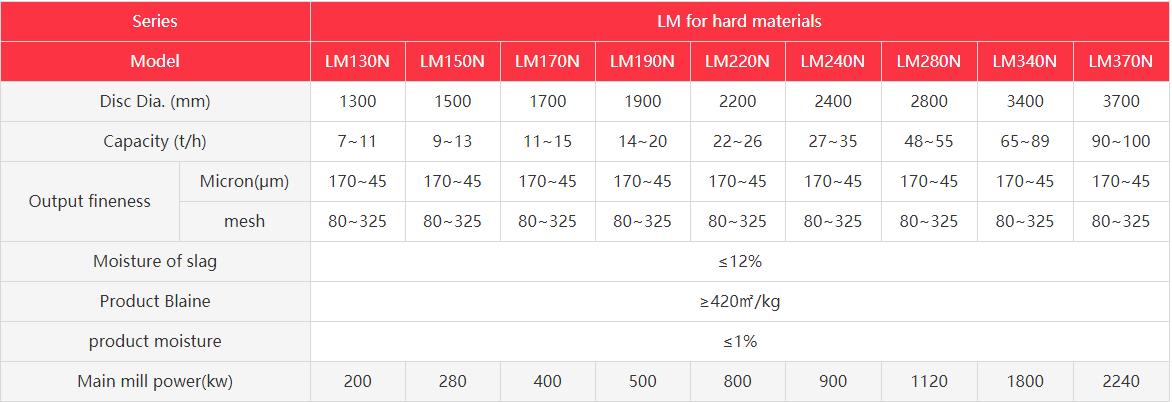

In the process of processing apatite into powder, LM vertical mill is a common powder making equipment. LM vertical mill is an advanced equipment which integrates crushing, drying, grinding, classifying and conveying. It has the advantages of simple process flow, compact structure, small footprint and high degree of automation. In addition, it adopts fully closed system and full negative pressure operation, no dust overflow, energy saving and environmental protection.The phosphatic limestone powder produced by LM vertical mill has uniform particle size, good fluidity and adaptability, which can improve production efficiency and product quality.

Apatite powder has a wide range of applications. The following are some common applications:

Sulfuric acid and cement raw materials: Apatite powder can be used as raw materials for the production of sulfuric acid and cement. By mixing apatite powder with other raw materials through suitable process treatment, high quality sulfuric acid and cement can be produced to meet the needs of industrial production.

Cement retarder: Apatite powder mixed with gypsum dihydrate can be used as a retarder for cement. The properties of this mixture are basically the same as those of natural gypsum, which can effectively control the setting speed of cement and improve the process performance of cement.

Chemical raw materials: Since phosphogypsum is rich in calcium and sulfide, it can be used as chemical raw materials after proper processing. These chemical raw materials can be widely used in the chemical industry for the production of various chemical products.

Through the rational use of apatite, we can realize the resourceful use of waste and reduce the dependence on natural resources while promoting sustainable development. The processing and application of apatite brings a variety of viable options for industrial production and chemistry, promoting the recycling of resources and environmental protection.

Previous: SMP Crusher

Next: SMP Crusher

Phosphogypsum is a kind of solid waste produced during the production of wet process phosphoric acid. The reasonable utilization of phosphogypsum can reduce the waste of resources and realize the sustainable development of resources. The main component

Phosphogypsum is a kind of solid waste produced during the production of wet process phosphoric acid. The reasonable utilization of phosphogypsum can reduce the waste of resources and realize the sustainable development of resources. The main components of apatite include calcium sulfate dihydrate, phosphate ore, residual phosphoric acid, fluoride, acid insoluble matter, organic matter, etc.

In the process of processing apatite into powder, LM vertical mill is a common powder making equipment. LM vertical mill is an advanced equipment which integrates crushing, drying, grinding, classifying and conveying. It has the advantages of simple process flow, compact structure, small footprint and high degree of automation. In addition, it adopts fully closed system and full negative pressure operation, no dust overflow, energy saving and environmental protection.The phosphatic limestone powder produced by LM vertical mill has uniform particle size, good fluidity and adaptability, which can improve production efficiency and product quality.

Apatite powder has a wide range of applications. The following are some common applications:

Sulfuric acid and cement raw materials: Apatite powder can be used as raw materials for the production of sulfuric acid and cement. By mixing apatite powder with other raw materials through suitable process treatment, high quality sulfuric acid and cement can be produced to meet the needs of industrial production.

Cement retarder: Apatite powder mixed with gypsum dihydrate can be used as a retarder for cement. The properties of this mixture are basically the same as those of natural gypsum, which can effectively control the setting speed of cement and improve the process performance of cement.

Chemical raw materials: Since phosphogypsum is rich in calcium and sulfide, it can be used as chemical raw materials after proper processing. These chemical raw materials can be widely used in the chemical industry for the production of various chemical products.

Through the rational use of apatite, we can realize the resourceful use of waste and reduce the dependence on natural resources while promoting sustainable development. The processing and application of apatite brings a variety of viable options for industrial production and chemistry, promoting the recycling of resources and environmental protection.

Previous: SMP Crusher

Next: SMP Crusher

How to deal with the uneven size of the mill discharge

How to deal with the uneven size of the mill discharge Essential equipment for efficient processing of quartz sand

Essential equipment for efficient processing of quartz sand How to choose stone to stone and stone to iron two kinds of crushing method

How to choose stone to stone and stone to iron two kinds of crushing method What are the production processes of sand and gravel aggregates

What are the production processes of sand and gravel aggregates How to distinguish sand as coarse or fine aggregate

How to distinguish sand as coarse or fine aggregate How to deal with the uneven size of the mill discharge

How to deal with the uneven size of the mill discharge Essential equipment for efficient processing of quartz sand

Essential equipment for efficient processing of quartz sand How to choose stone to stone and stone to iron two kinds of crushing method

How to choose stone to stone and stone to iron two kinds of crushing method What are the production processes of sand and gravel aggregates

What are the production processes of sand and gravel aggregates How to distinguish sand as coarse or fine aggregate

How to distinguish sand as coarse or fine aggregate