How to choose crushing equipment for building a stone production line in Linyi, Shandong?Linyi, Shandong has rich mineral resources, such as granite, limestone, etc., so how to choose equipment for building a limestone crushing produ

How to choose crushing equipment for building a stone production line in Linyi, Shandong?

Linyi, Shandong has rich mineral resources, such as granite, limestone, etc., so how to choose equipment for building a limestone crushing production line? The following mainly introduces how to configure the crusher production line:

800t/h-900t/h limestone crushing production line case:

Feed size: 0-600mm

Discharge size: 0-6mm, 6-11mm, 11-21mm, 21-41mm

Equipment selection: jaw crusher, European version jaw crusher, European version impact crusher

The main process is as follows:

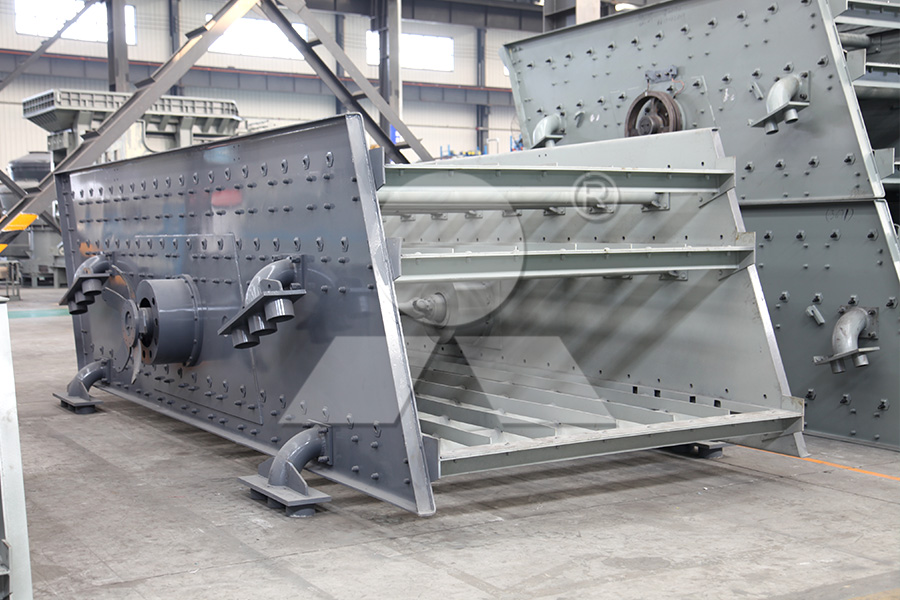

Introduction to main equipment:

1. Jaw crusher: This is a large jaw crusher, especially suitable for coarse crushing operations. It has high crushing efficiency and long service life, and can handle ores and rocks of various hardness.

2. European version jaw crusher: This jaw crusher also focuses on coarse crushing operations, especially suitable for the crushing of small and medium-sized ores. Its output size is about 130-270 mm, and its output can reach 280-600 tons per hour. It is an efficient choice for crushing limestone, diabase and other materials.

3. European impact crusher: As an impact crusher, it is mainly used for medium and fine crushing operations. The equipment has a long service life and low maintenance cost. The processing capacity is between 200-300 tons/hour and is suitable for ores and rocks of various hardness.

Previous: SMP Crusher

Next: SMP Crusher

How to choose crushing equipment for building a stone production line in Linyi, Shandong?Linyi, Shandong has rich mineral resources, such as granite, limestone, etc., so how to choose equipment for building a limestone crushing produ

How to choose crushing equipment for building a stone production line in Linyi, Shandong?

Linyi, Shandong has rich mineral resources, such as granite, limestone, etc., so how to choose equipment for building a limestone crushing production line? The following mainly introduces how to configure the crusher production line:

800t/h-900t/h limestone crushing production line case:

Feed size: 0-600mm

Discharge size: 0-6mm, 6-11mm, 11-21mm, 21-41mm

Equipment selection: jaw crusher, European version jaw crusher, European version impact crusher

The main process is as follows:

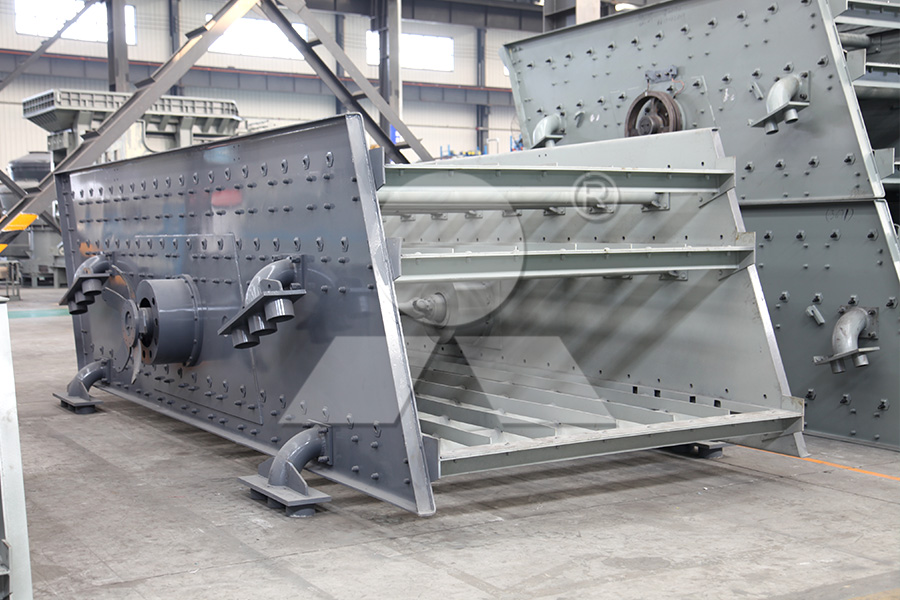

Introduction to main equipment:

1. Jaw crusher: This is a large jaw crusher, especially suitable for coarse crushing operations. It has high crushing efficiency and long service life, and can handle ores and rocks of various hardness.

2. European version jaw crusher: This jaw crusher also focuses on coarse crushing operations, especially suitable for the crushing of small and medium-sized ores. Its output size is about 130-270 mm, and its output can reach 280-600 tons per hour. It is an efficient choice for crushing limestone, diabase and other materials.

3. European impact crusher: As an impact crusher, it is mainly used for medium and fine crushing operations. The equipment has a long service life and low maintenance cost. The processing capacity is between 200-300 tons/hour and is suitable for ores and rocks of various hardness.

Previous: SMP Crusher

Next: SMP Crusher

High-efficiency and environmentally friendly limestone sand production line with an annual output of 1.2 million tons

High-efficiency and environmentally friendly limestone sand production line with an annual output of 1.2 million tons How to choose a jaw crusher manufacturer

How to choose a jaw crusher manufacturer Manganese ore crushing solution with a daily processing capacity of 4,000 tons

Manganese ore crushing solution with a daily processing capacity of 4,000 tons Granite and basalt cone crusher models introduction

Granite and basalt cone crusher models introduction How much does a large sand making machine cost

How much does a large sand making machine cost High-efficiency and environmentally friendly limestone sand production line with an annual output of 1.2 million tons

High-efficiency and environmentally friendly limestone sand production line with an annual output of 1.2 million tons How to choose a jaw crusher manufacturer

How to choose a jaw crusher manufacturer Manganese ore crushing solution with a daily processing capacity of 4,000 tons

Manganese ore crushing solution with a daily processing capacity of 4,000 tons Granite and basalt cone crusher models introduction

Granite and basalt cone crusher models introduction How much does a large sand making machine cost

How much does a large sand making machine cost